Leave Your Message

In recent years, the use of Zirconia Ceramic has gained remarkable traction in various industrial applications due to its unique properties and advantages. As outlined in a report by Grand View Research, the global zirconia ceramics market is expected to reach USD 3.53 billion by 2025, driven by its increasing adoption in healthcare, electronics, and automotive industries. Notably, Zirconia Ceramic is known for its exceptional hardness, chemical resistance, and thermal stability, making it an ideal choice for cutting tools, dental implants, and advanced electronic components.

With the rise of technologies demanding high-performance materials, understanding the benefits of Zirconia Ceramic is crucial for industries looking to innovate and enhance operational efficiency. This blog will explore the transformative role of Zirconia Ceramic in modern industrial settings, highlighting its applications and the significant advantages it offers over traditional materials.

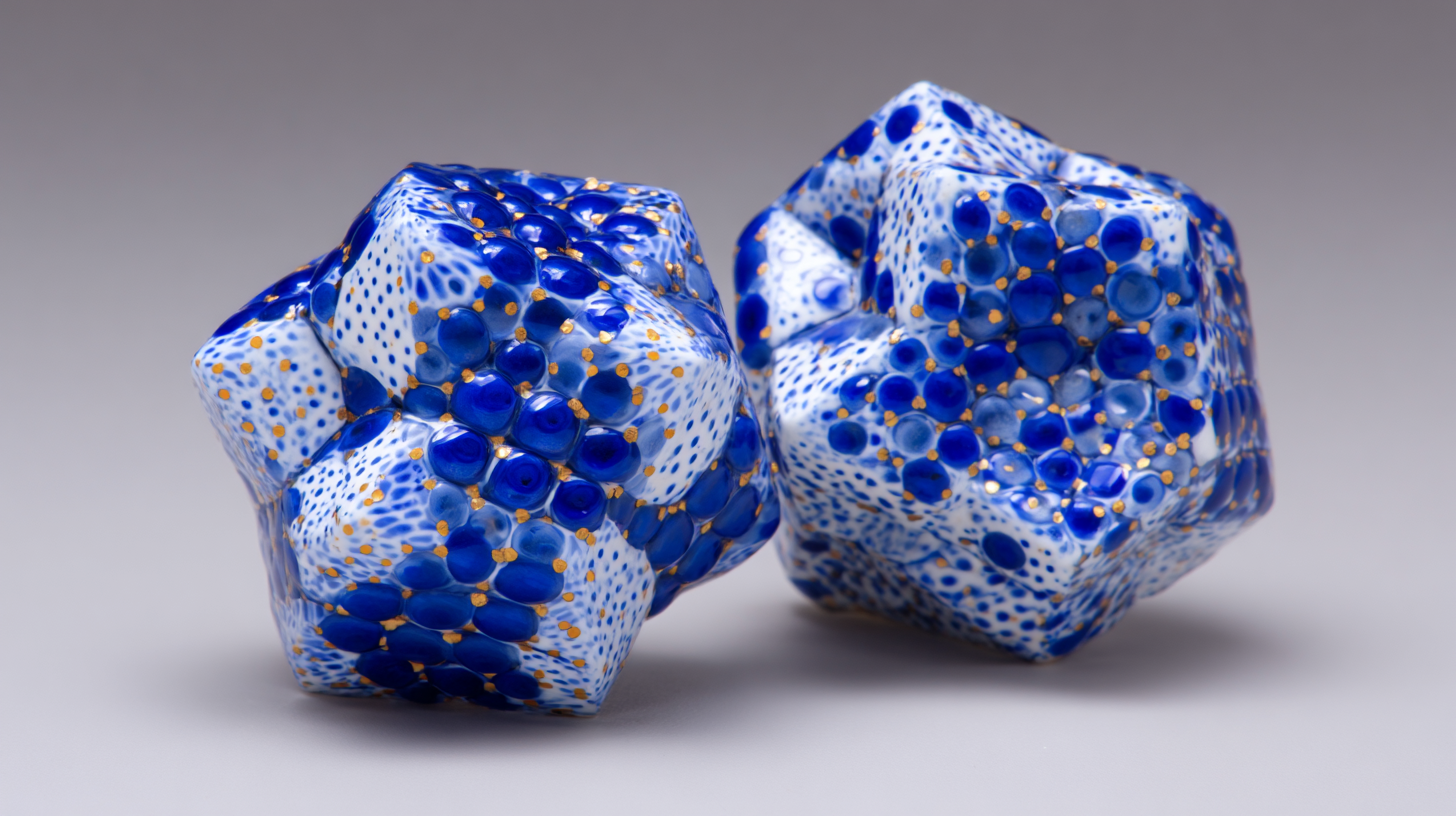

Zirconia ceramic has gained significant attention in modern industrial applications due to its unique properties and numerous benefits. With its exceptional mechanical strength and toughness, zirconia plays a vital role in environments that demand high durability and resistance to wear. Its ability to withstand extreme temperatures and corrosion makes it suitable for industries such as aerospace, automotive, and medical, where reliability is paramount.

One of the standout characteristics of zirconia ceramic is its low thermal conductivity, which enhances energy efficiency in various applications. Additionally, zirconia exhibits excellent biocompatibility, making it an ideal choice for medical implants and dental prosthetics. The material's aesthetic appeal, combined with its ability to retain its structural integrity under stress, positions it as a preferred option for complex industrial components that require both functionality and visual quality. As industries continue to evolve, the advantages of zirconia ceramic will undoubtedly play a crucial role in driving innovation and performance.

In modern industrial applications, the advantages of using zirconia ceramics are increasingly recognized, particularly in fields such as dental and additive manufacturing. The introduction of Zirconium Oxide Ceramic Dental Blanks, classified under tariff heading 6909 for GST purposes, highlights the product's relevance as a high-performance material specifically designed for laboratory use. This classification not only ensures compliance but also indicates the growing acceptance of zirconia ceramics in specialized applications.

Moreover, the role of effective after-sales service cannot be overstated when it comes to maximizing the performance of zirconia ceramics. Research indicates that enhancements in post-purchase support can lead to significant improvements in product longevity and effectiveness, which is critical in high-stakes environments like dental labs. According to VoxelMatters Research, the ceramic additive manufacturing market is poised for substantial growth by 2025, driven by technological advancements and increased demand for high-quality materials. Ensuring that users have access to comprehensive after-sales services could ultimately facilitate better outcomes, fostering innovation and efficiency in this expansive and evolving market.

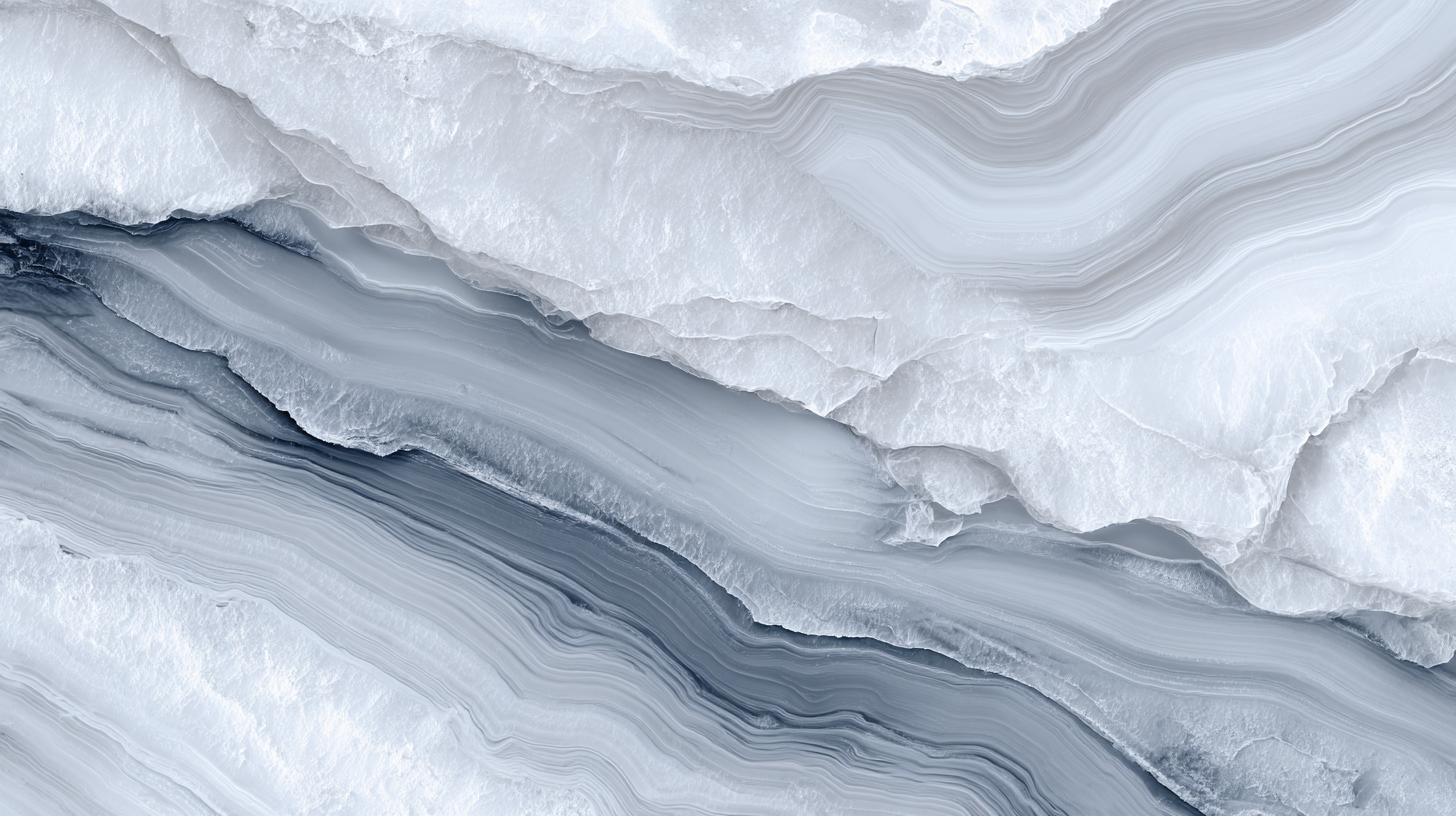

Zirconia ceramics are increasingly recognized for their exceptional longevity and resilience, making them a preferred choice in various industrial applications. Not only do they offer superior mechanical properties, but they are also proving to be cost-effective over time. By implementing regular maintenance strategies, industries can significantly reduce overall operating costs. Recent studies have highlighted that routine inspection and surface treatments can extend the lifespan of zirconia products dramatically, reducing the need for frequent replacements.

Moreover, with the rise of advanced manufacturing techniques like 3D printing, zirconia ceramics are paving the way for innovative applications, particularly in the medical sector. The development of customized bone scaffolds using zirconia and other bioceramics demonstrates their effectiveness in wound healing, providing a biocompatible and economical solution for patients. As industries adopt these cutting-edge materials and technologies, the potential for cost savings continues to enhance the appeal of zirconia ceramics across various applications, confirming their status as a valuable asset in modern manufacturing and healthcare solutions.

When selecting the right zirconia ceramic for specific industrial applications, it is essential to consider the unique properties of zirconia. This advanced material is known for its exceptional strength, durability, and resistance to wear and corrosion. Industries that require components to withstand harsh conditions, such as aerospace, automotive, and medical fields, often rely on zirconia ceramics for their reliability. Look for zirconia compositions that align with the operating environment of your application, as variations in zirconia can affect performance under specific thermal and mechanical conditions.

In addition to material properties, the design and processing of zirconia ceramics play a critical role in their application. Understanding the manufacturing techniques, such as sintering and molding, can help in selecting the right type of zirconia for intricate parts or high-stress components. Working closely with suppliers that offer customizable solutions can further ensure that the chosen zirconia ceramic meets the precise requirements necessary for optimum performance. Furthermore, consider the cost-effectiveness of different zirconia grades, as balancing quality and budget can lead to longer-lasting and more efficient industrial outcomes.

| Application Area | Properties | Advantages | Selecting Criteria |

|---|---|---|---|

| Dental Ceramics | High translucency, biocompatibility, strength | Aesthetic appeal, durability | Consider shade matching and strength needed |

| Aerospace Components | High strength-to-weight ratio, thermal stability | Reduced weight, enhanced performance | Focus on temperature resistance and weight |

| Cutting Tools | Hardness, toughness, wear resistance | Longer tool life, improved cutting performance | Select based on material type and cutting conditions |

| Electrical Insulators | High dielectric strength, thermal insulation | Effective insulation, enhanced safety | Ensure voltage rating and thermal properties |

| Biomedical Applications | Corrosion resistance, biocompatibility | Safe for implants, longevity | Assess compatibility with human tissue |

Zirconia ceramic has emerged as a revolutionary material in various modern industrial applications, owing to its exceptional properties such as high strength, thermal stability, and resistance to wear and corrosion. Industries ranging from aerospace to medical are increasingly integrating zirconia ceramics into their processes. For instance, in the aerospace sector, zirconia's lightweight and high-temperature resistance make it an ideal choice for components subjected to extreme conditions. Furthermore, in the medical field, zirconia is being utilized for dental implants and prosthetics, showcasing its biocompatibility and durability.

The innovative applications of zirconia ceramics extend beyond traditional uses, with advancements in technology paving the way for new possibilities. The rise of 3D printing, for example, has unlocked new manufacturing techniques that allow for precise and efficient production of complex zirconia structures. This trend not only enhances the customization capabilities within industries but also contributes to a more sustainable production model. As the advanced ceramics market continues to expand, projected to reach USD 16.27 billion by 2029, the demand for high-performance materials like zirconia ceramics will undoubtedly grow, driving further innovation across diverse sectors.