Leave Your Message

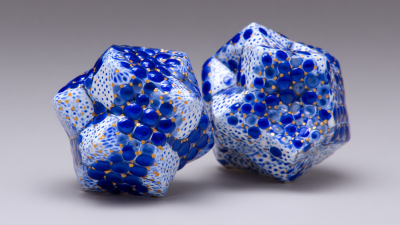

In the realm of advanced materials, the Corundum Mullite Plate stands out as a highly versatile and indispensable component across various modern industries. Its unique combination of high thermal stability, excellent mechanical strength, and resistance to thermal shock makes it an ideal choice for applications ranging from refractory linings in furnaces to components in aerospace engineering. As industries increasingly seek alternatives to traditional materials that become outdated or fail to meet the rigorous demands of contemporary manufacturing processes, the Corundum Mullite Plate emerges as a compelling solution. By exploring the diverse applications of this remarkable material, we can uncover its potential to revolutionize existing practices while addressing the pressing need for innovative alternatives in high-temperature environments. This blog will delve into the multifaceted uses of Corundum Mullite Plates, highlighting how they offer not only efficiency and durability but also pave the way for advancements in industrial technology.

Corundum mullite plates have emerged as a pivotal material in high-temperature applications across various industries, including aerospace, metallurgy, and ceramics. These advanced ceramic composites boast remarkable thermal stability and mechanical strength, making them ideal for use in environments that reach temperatures above 1600°C. A report from the International Ceramic Society cites that the global demand for high-temperature materials is projected to grow by 7% annually, which underscores the increasing reliance on materials like corundum mullite in industrial processes.

In addition to their thermal properties, corundum mullite plates offer excellent resistance to thermal shock and abrasion, which is essential for applications such as kiln linings and furnace components. A case study from the American Society of Materials suggests that the implementation of corundum mullite in industrial furnaces can reduce energy costs by up to 20%, proving both economical and efficient.

**Tips for Optimization:**

When choosing corundum mullite plates for your applications, consider the specific temperature ranges and mechanical stresses your material will face. It's also beneficial to conduct a thorough assessment of the plate’s grain structure, as finer grains often yield better thermal shock resistance. Evaluate potential suppliers for their quality control processes, ensuring the materials meet industry standards for high-temperature applications.

The manufacturing process of corundum mullite plates presents several challenges that engineers and manufacturers must navigate to ensure high-quality products. One significant issue is the precise temperature control required during the firing process. Any fluctuations can result in uneven properties, affecting the durability and efficacy of the plates. Maintaining a consistent atmosphere in kilns is essential for achieving the desired phase stability and mechanical strength, which are critical for their application in high-temperature environments.

Tips for improving the manufacturing process include investing in advanced kiln technologies that allow for greater control over firing conditions. Additionally, utilizing high-purity raw materials can mitigate the risk of contamination, resulting in superior quality plates. Regular maintenance and calibration of equipment will also play a crucial role in maintaining production standards.

Another challenge is the handling of the raw materials before fabrication. Corundum and mullite components should be stored properly to prevent moisture absorption, which can compromise the final product. Ensuring a clean and efficient workspace will further enhance operational efficiency. Proper training for personnel involved in the manufacturing process is vital to minimize errors and streamline production, ultimately leading to higher-quality corundum mullite plates for modern industrial applications.

Corundum mullite, recognized for its exceptional thermal stability and mechanical strength, stands out in a variety of industrial applications, particularly when compared to other ceramic materials. Its unique composition, which combines alumina and silica, gives it enhanced resistance to thermal shock and wear, making it an ideal choice for high-temperature environments such as furnaces, kiln linings, and aerospace applications. In contrast, other ceramics, such as porcelain or traditional stoneware, often cannot withstand the demanding conditions faced in these industries.

When analyzing corundum mullite against other advanced ceramics like silicon carbide and zirconia, it becomes evident that each material has its own strengths. Silicon carbide is known for its hardness and low thermal expansion, which may be beneficial in machining applications. However, corundum mullite offers superior thermal shock resistance, which is crucial for processes involving rapid temperature fluctuations. Zirconia, while exceptional in toughness, can face challenges in high-temperature scenarios due to its phase transformation. Therefore, industries seeking a middle ground between performance and cost-effectiveness often find corundum mullite to be the optimal choice, combining durability and versatility for modern manufacturing processes.

Corundum mullite plates are emerging as integral components in various industrial applications, significantly enhancing energy efficiency. These advanced ceramics, known for their excellent thermal stability, low thermal conductivity, and resistance to wear, make them ideal for high-temperature environments such as kilns and furnaces. By providing superior insulation, corundum mullite plates reduce heat loss, leading to lower energy consumption and enhanced operational efficiency. This is particularly crucial in industries where energy costs are a significant concern, such as the steel and glass manufacturing sectors.

Furthermore, the use of corundum mullite plates contributes to improved product quality and operational reliability. Their high resistance to thermal shock minimizes the risk of failure due to sudden temperature changes, which can lead to costly downtimes. By maintaining optimal temperature profiles, these plates not only preserve the integrity of the materials being processed but also ensure consistent product outcomes. As industries seek to adopt more sustainable practices, the implementation of corundum mullite technology is positioned as a key strategy for enhancing energy efficiency while minimizing environmental impact.

The technology and applications of corundum mullite plates are poised for significant advancements in the coming years. With industries increasingly prioritizing high-performance materials, the demand for corundum mullite—renowned for its excellent thermal stability, corrosion resistance, and mechanical strength—continues to rise. According to a report from Allied Market Research, the global refractory materials market is expected to reach $30 billion by 2026, growing at a CAGR of 5.5%. Corundum mullite plates are emerging as key components in sectors such as aerospace, automotive, and ceramics, primarily due to their ability to withstand extreme temperature fluctuations and harsh environments.

As we look to the future, one notable trend is the integration of advanced ceramics technology in the production of corundum mullite plates. Innovations such as nano-structured materials and enhanced processing techniques are likely to improve their performance characteristics. Emerging applications in electric vehicles and renewable energy systems highlight the versatility of corundum mullite. For instance, as stated in a recent market analysis by Research and Markets, the increasing adoption of high-temperature insulation materials in the automotive sector is a driving force for growth, indicating a shift towards more sustainable manufacturing methodologies.

Tips: When considering corundum mullite plates for industrial applications, ensure to specify the thermal and mechanical requirements of your project. Engaging with suppliers who can provide detailed performance data can lead to better material choices. Additionally, keep an eye on technological advancements in ceramic processing that may provide enhanced material properties tailored to your needs.