Leave Your Message

In the industrial world, materials can profoundly impact efficiency and performance. One such material gaining attention is the Cordierite Mullite Plate. Expert John Smith, a materials scientist, notes, "Cordierite Mullite Plates hold significant potential in high-temperature applications." This statement emphasizes the unique advantages offered by these plates.

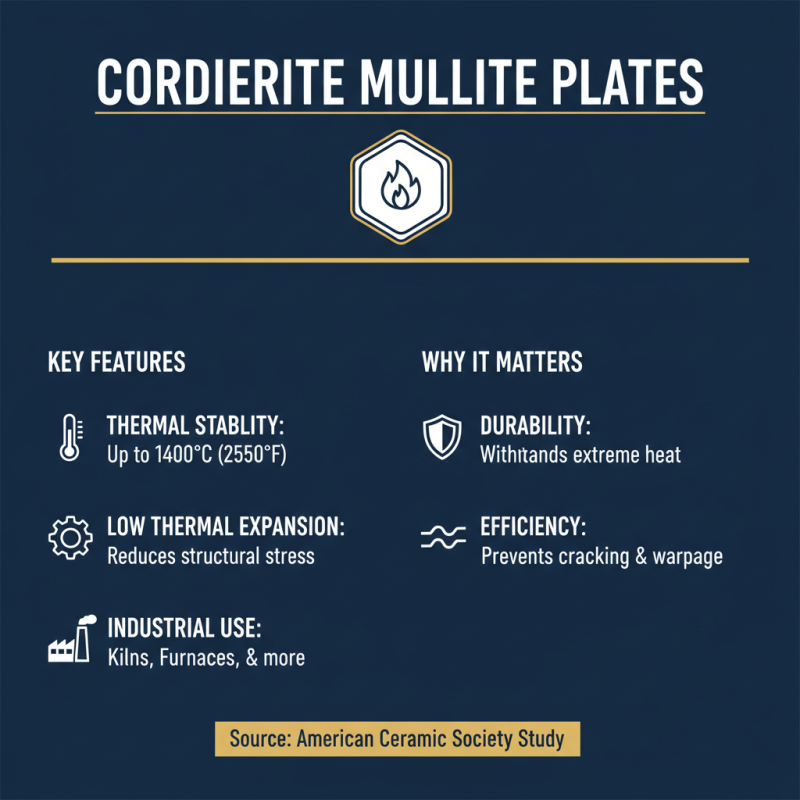

Manufacturers are increasingly utilizing Cordierite Mullite Plates for their thermal stability. These plates withstand extreme temperatures, making them suitable for various industrial processes. Moreover, they exhibit excellent resistance to thermal shock. This characteristic can save companies money by reducing equipment wear and tear.

Another aspect to consider is the balance between performance and cost. While Cordierite Mullite Plates provide exceptional benefits, their initial investment can be substantial. Organizations must evaluate their long-term gains versus upfront costs. Ultimately, the decision to implement these plates should be thoroughly assessed to ensure a sustainable manufacturing approach.

Cordierite mullite plates offer numerous benefits for industrial applications. These materials excel due to their excellent thermal stability. They can withstand extreme temperatures, making them ideal for high-heat environments. In steel manufacturing or glass production, for example, these plates perform reliably. Their resistance to thermal shock is another essential aspect. Rapid temperature changes can cause damage to inferior materials, but cordierite mullite holds up well.

Another advantage is their low thermal conductivity. This feature is particularly beneficial in processes where heat retention is crucial. By using cordierite mullite plates, industries can enhance energy efficiency. This not only saves costs but also reduces environmental impact. The durability of these plates is notable as well. They can last longer under harsh operating conditions, minimizing replacement needs.

However, there are some considerations. The initial investment may be higher compared to other materials. Not every application may warrant this expense. Organizations must assess their specific needs and weigh the long-term benefits. Also, proper installation and maintenance are critical for maximizing performance. Skipping these steps could lead to premature failure.

Cordierite mullite plates excel in thermal stability, making them ideal for industrial applications. In high-temperature environments, they can withstand heat up to 1,400 degrees Celsius. This feature is crucial for environments like kilns or furnaces. A study by the American Ceramic Society notes that materials with low thermal expansion rates, like cordierite, help in reducing stress on structures during thermal cycles.

The thermal shock resistance of cordierite mullite plates is also noteworthy. They can handle sudden temperature changes without cracking. According to recent findings, these plates exhibit a thermal shock resistance value greater than 60 MPa, significantly outperforming traditional materials. This makes them a suitable choice where rapid heating and cooling occur. However, the performance can vary based on composition and manufacturing processes.

Despite these advantages, there are areas for improvement. For example, cordierite can be more brittle compared to other materials. This brittleness can lead to unexpected failures under certain conditions. Continuous research is necessary to understand the limits of these materials. Validating long-term performance in real-world applications can uncover potential weaknesses.

In the world of industrial ceramics, cordierite mullite plates stand out for their mechanical strength. Mechanical properties are crucial for demanding applications. According to recent studies, cordierite mullite exhibits high compressive strength exceeding 100 MPa. This combines well with thermal stability, making it suitable for high-temperature environments.

When comparing with alternative materials like alumina and silicon carbide, cordierite mullite shows notable advantages. Alumina, while strong, can be brittle. Its fracture toughness is comparatively lower, leading to potential failure in heavy-duty situations. In contrast, silicon carbide, though tough, is often more expensive and less available. Cordierite mullite strikes a balance between performance and cost, making it an attractive choice.

Some might argue the limits of cordierite mullite. Its strength can decrease in certain conditions, like rapid thermal cycling. Research indicates that improper handling can cause micro-cracks, affecting longevity. These aspects warranted further investigation to improve material resilience. By understanding these limitations, industries can better utilize this versatile material for high-demand tasks.

Cordierite mullite plates are becoming a popular choice in various industrial applications. One significant advantage is their impressive corrosion resistance. In industries where reactive substances are present, this feature is crucial. Plates made from cordierite mullite endure harsh conditions, minimizing damage over time. They resist oxidation and various chemical attacks. This durability can lead to less frequent replacements.

The impact on maintenance costs is notable. Industries save money in the long run due to fewer repairs and replacements. Regular maintenance becomes less intensive when using these plates. However, it is essential to monitor their performance consistently. While they are robust, neglect can lead to unforeseen issues. A small crack can expand under stress, compromising the entire plate. Regular inspection helps catch problems early.

The overall longevity of these materials boosts efficiency. Longer-lasting plates mean reduced downtime. Yet, not all applications yield the same results. Some environments may still present challenges. Understanding the specific needs of a process is vital for optimal performance. Companies must consider all factors to reap the full benefits of cordierite mullite plates.

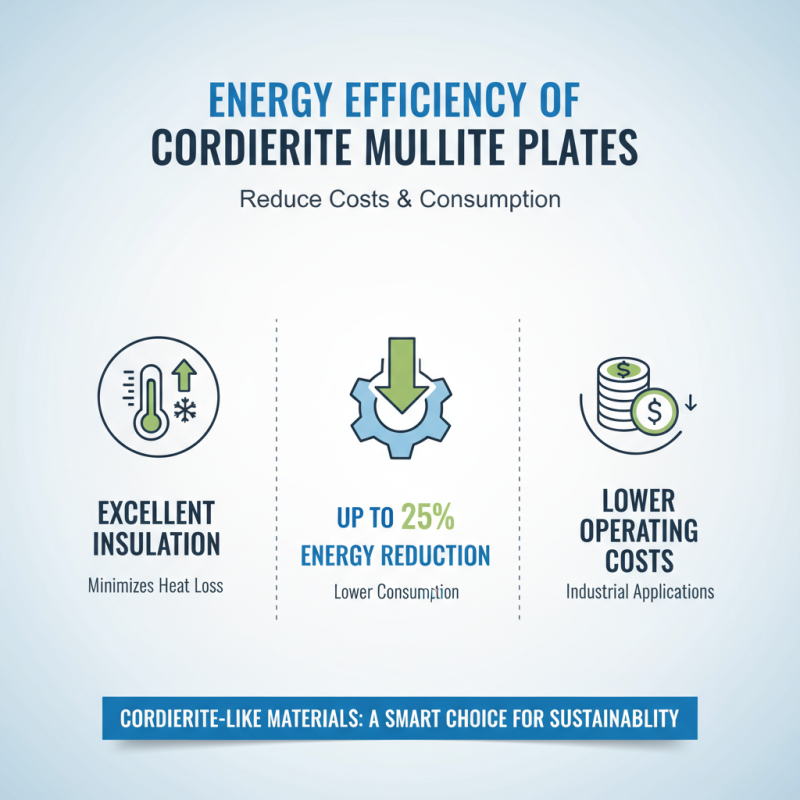

Cordierite mullite plates have gained attention for their energy efficiency. These materials are known for their excellent insulation properties. According to recent industry reports, using cordierite-like materials can reduce energy consumption by up to 25%. This significant reduction translates directly into lower operating costs for many industrial applications.

Energy efficiency is a crucial factor in today’s manufacturing processes. Cordierite mullite plates minimize heat loss, thus maintaining optimal temperatures. As the temperature remains stable, the need for additional heating is reduced. This not only saves energy but also lowers greenhouse gas emissions in the long run.

**Tip:** Regularly check insulation materials for wear and tear to ensure maximum efficiency.

Moreover, companies employing these plates can benefit from extended equipment life. The enhanced thermal stability of cordierite helps prevent thermal shock. However, despite its advantages, there can be challenges in adapting these materials to existing systems. Each facility's unique setup may require some adjustments, which could incur costs.

**Tip:** Consult with experts when integrating new materials to avoid costly mistakes.

Incorporating cordierite mullite plates can be a game-changer, but it’s essential to assess your specific industrial needs. Understanding what fits best can lead to sustainable growth and cost reductions.