Leave Your Message

In the ever-evolving landscape of modern manufacturing, innovation is key to maintaining a competitive edge. Among the various materials that have emerged as essential components in contemporary manufacturing techniques, Cordierite Mullite Plates stand out due to their remarkable thermal stability and mechanical strength. Renowned expert Dr. Emily Zhang, a materials science specialist at the Advanced Materials Institute, notes, "The unique properties of Cordierite Mullite Plates not only enhance the manufacturing process but also contribute significantly to the durability and efficiency of the end products."

The use of Cordierite Mullite Plates in manufacturing is particularly beneficial in processes that involve high-temperature applications. Their ability to withstand thermal shock and resist deformation under stress positions them as a preferred choice in industries ranging from aerospace to ceramics. Furthermore, these plates offer exceptional insulating properties, reducing energy consumption during production and improving overall cost efficiency.

As we delve deeper into the benefits of Cordierite Mullite Plates, it becomes evident that they are not just a material choice but a strategic asset in optimizing production techniques. Embracing the advantages of this innovative material can lead to substantial improvements in product quality and operational performance, thus reshaping the future of manufacturing.

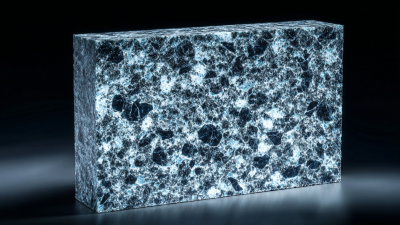

Cordierite mullite plates have emerged as a vital component in high-temperature applications due to their exceptional thermal stability and mechanical properties. These plates are characterized by their ability to withstand extreme temperatures without significant deformation or degradation. This makes them ideal for use in environments such as kilns, furnaces, and even in aerospace applications where materials are subject to severe thermal stress. The low thermal conductivity of cordierite mullite also ensures that heat is retained effectively, enhancing energy efficiency in industrial processes.

In addition to their thermal properties, cordierite mullite plates exhibit impressive resistance to thermal shock, which is critical in manufacturing where rapid temperature fluctuations can occur. This resilience helps to extend the lifespan of the components and reduces maintenance costs over time. Furthermore, their lightweight nature compared to traditional materials contributes to improved handling and installation, facilitating streamlined manufacturing processes. Overall, the integration of cordierite mullite plates into high-temperature applications not only optimizes performance but also drives innovation in modern manufacturing techniques.

| Property | Description | Advantages |

|---|---|---|

| Thermal Stability | Excellent resistance to thermal shock and high temperatures | Reduces the risk of cracking and improves lifespan in high-heat applications |

| Low Thermal Expansion | Minimized dimensional changes under varying temperatures | Maintains structural integrity and accuracy in precision applications |

| Chemical Resistance | Resistant to various chemicals and corrosive substances | Ideal for use in harsh environments, enhancing durability |

| Lightweight | Lower density compared to traditional ceramics | Eases handling and decreases support structure requirements |

| Fabrication Versatility | Can be shaped and formed into various configurations | Accommodates a wide range of manufacturing needs and processes |

Cordierite mullite plates have emerged as a vital component in modern manufacturing, particularly due to their enhanced thermal stability. These plates exhibit excellent resistance to thermal shock, which is crucial in industries where sudden temperature fluctuations occur. According to a report by the International Journal of Applied Ceramic Technology, cordierite mullite composites can withstand temperature variations of over 1,000°C without significant structural failure, making them ideal for applications in high-temperature environments such as kilns and furnaces.

Moreover, the thermal expansion coefficient of cordierite mullite is remarkably low, ranging from 2.5 to 3.0 x 10^-6/K, which minimizes warping and cracking during the cooling and heating processes. This property is especially beneficial for precision manufacturing, ensuring that components maintain their integrity, leading to enhanced product quality and reduced waste. As the manufacturing sector continues to prioritize efficiency and sustainability, the use of cordierite mullite plates aligns well with these goals by decreasing downtime and improving the overall performance of thermal processes.

Cordierite mullite plates have emerged as a pivotal material in modern manufacturing techniques, particularly in their ability to significantly reduce production costs. These plates exhibit exceptional thermal stability and resistance to thermal shock, making them ideal for high-temperature applications. This characteristic ensures that manufacturers can maintain operation efficiencies while minimizing the risk of product defects caused by thermal stresses.

Furthermore, the lightweight nature of cordierite mullite plates allows for easier handling and installation in various manufacturing settings. Reducing the weight of components can lead to lower energy costs during transportation and assembly. Additionally, their durability means that manufacturers can expect a longer lifespan from their equipment and materials, further diminishing the frequency and costs associated with replacements and repairs.

Overall, the integration of cordierite mullite plates into manufacturing processes presents a strategic advantage for companies striving to optimize efficiency and reduce operational expenses.

Cordierite mullite plates are gaining recognition in industrial settings due to their exceptional corrosion resistance, making them a preferred choice in modern manufacturing techniques. These plates exhibit remarkable durability against aggressive chemicals and environmental conditions, which is crucial for industries such as ceramics, glass, and metal processing. Their ability to withstand corrosive agents without degradation significantly enhances operational efficiency and extends the lifespan of manufacturing components.

In addition to their corrosion resistance, cordierite mullite plates offer excellent thermal stability and low thermal expansion. This combination of properties ensures that they maintain structural integrity under fluctuating temperatures, which is common in industrial processes. By choosing these plates, manufacturers can minimize equipment downtime caused by corrosion-related failures, thereby optimizing productivity and ensuring the quality of the end products. As industries seek more reliable materials, the integration of cordierite mullite plates is poised to revolutionize various manufacturing applications.

Innovative manufacturing processes are increasingly embracing cordierite mullite technology due to its exceptional thermal stability and mechanical strength. According to a report by MarketsandMarkets, the market for advanced ceramics is expected to reach $109.77 billion by 2025, with cordierite mullite specifically gaining traction in sectors that require high-temperature resistance, such as aerospace and automotive. This material's low thermal expansion coefficient makes it ideal for applications like kiln furniture and refractory linings, where stability under thermal stress is critical.

Furthermore, industries are leveraging the lightweight nature of cordierite mullite plates to enhance efficiency. The latest analysis from Research and Markets highlights that using lighter materials can improve energy efficiency during manufacturing processes by up to 20%. Innovations in the production methods of cordierite mullite, such as additive manufacturing techniques, are also paving the way for complex geometries that were previously unattainable through traditional means. This adaptability not only reduces material waste but also accelerates the development cycle of new products, offering manufacturers a competitive edge in a rapidly evolving marketplace.