Leave Your Message

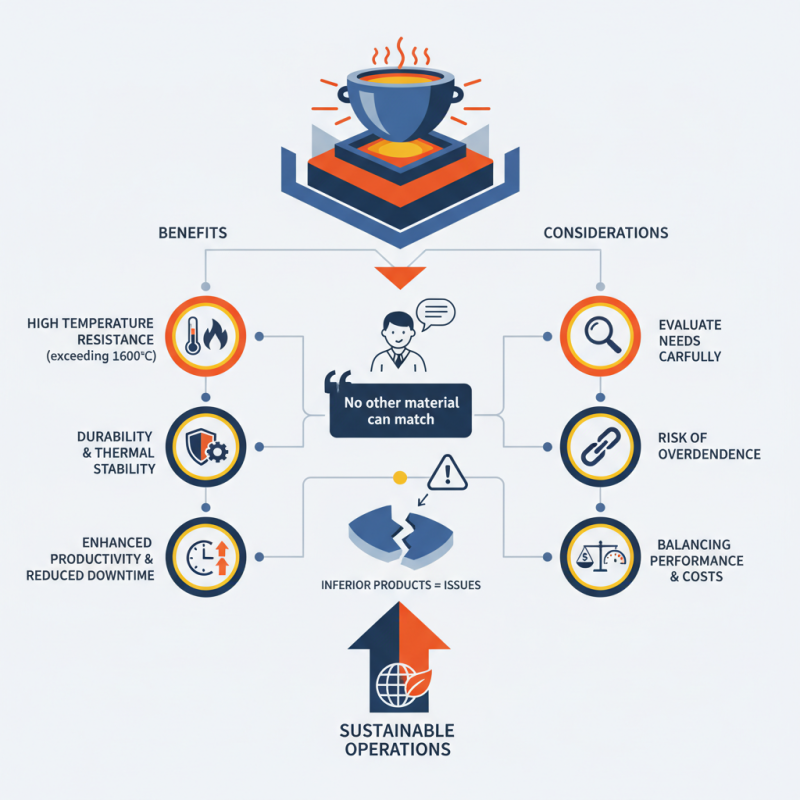

The use of Corundum Mullite Sagger has gained traction in industrial applications. Industry reports indicate that saggers made from corundum mullite can withstand high temperatures, often exceeding 1,600 degrees Celsius. This is crucial for various high-temperature processes, including ceramics and glass manufacturing.

Expert Tom Richards emphasizes the importance of these materials: "Corundum Mullite Saggers provide durability and thermal stability that no other material can match." Such properties enhance productivity and reduce downtime in manufacturing setups. However, not all saggers are created equal, and selecting inferior products can lead to significant issues.

Despite the advantages, companies must evaluate their needs carefully. There’s a risk of overdependence on high-performance saggers. For instance, as industries push for even higher efficiencies, the long-term reliability of Corundum Mullite Saggers needs further investigation. Balancing performance and costs is vital for sustainable operations.

Corundum mullite sagger is gaining traction in various industrial applications. This material is known for its high thermal stability and excellent resistance to thermal shock. In industries like ceramics and metal casting, these properties prove vital. Sagger ensures products maintain their shape and integrity during high-temperature processes.

Another advantage is its durability. Corundum mullite saggers withstand harsh environments, reducing the need for frequent replacements. This longevity translates into cost savings for manufacturers. However, one must consider the initial investment, as these saggers can be costly. Weighing immediate expenses against long-term benefits is crucial.

Tips: Always monitor the operating conditions of your sagger. Frequent inspections can prevent unexpected failures. Ensure proper handling during loading and unloading. This can help maintain the sagger's strength over time. Adopting preventive measures will enhance its lifespan.

Corundum mullite sagger stands out for its thermal stability. This material can withstand extreme temperatures. It's ideal for high-temperature applications. The composition includes corundum and mullite, providing excellent strength. This helps to prevent deformation during firing processes.

In harsh environments, thermal fluctuations can be damaging. However, corundum mullite saggers maintain their structure. They resist cracking and warping, which is crucial in industries like ceramics. Production downtime is costly, and material failures can create delays. Hence, reliable thermal stability can enhance overall productivity.

This material can be expensive, but the benefits outweigh the costs. Consider the implications of frequent replacements. Investing in high-quality saggers leads to consistent performance. Even minor improvements in thermal stability can translate into significant savings. The challenge lies in balancing cost and durability. Exploring different suppliers could provide better options.

This chart illustrates the enhanced benefits of using Corundum Mullite Sagger in high-temperature applications. The data represents the thermal stability, chemical resistance, and overall durability compared to other materials.

Corundum mullite saggers are becoming popular in various industrial applications. These saggers provide improved mechanical strength over traditional materials. Enhanced strength means less risk of breakage during high-temperature processes. This is crucial in environments where durability is essential.

The manufacturing process of these saggers is noteworthy. They often endure extreme conditions, making their strength significant. For example, during firing, traditional saggers might crack under stress. In contrast, corundum mullite saggers maintain structural integrity better. This reliability can reduce downtime and lower production costs.

However, it's essential to consider the trade-offs. Production of corundum mullite saggers can be more energy-intensive. This raises questions about sustainability in their use. There’s room for improvement in balancing strength and environmental impact. Industries must reflect on these factors as they choose materials.

Corundum mullite saggars play a crucial role in shaping the quality of fired products. These saggars, made from high-purity materials, withstand extreme temperatures. Research shows that using corundum mullite saggars can improve thermal stability. This stability results in better dimensional control of ceramics during firing. One study indicated a 10% reduction in warpage compared to traditional saggars.

The impact on finished products is significant. The saggars help maintain uniform heating in kilns. This ensures that every item receives consistent treatment. Uneven heat can lead to defects. Moreover, corundum mullite's resistance to chemical corrosion protects fired goods. Over 80% of manufacturers reported an increase in quality when switching to these saggars. Yet, some challenges exist. Cost can be higher than standard options. Not all facilities can justify this investment.

Manufacturers must weigh benefits against costs. A detailed analysis is crucial for optimal decision-making. While corundum mullite saggars deliver many advantages, they may not suit every production line. Essential insights can drive innovation and improve overall output. Continual assessment of material performance is vital for future advancements.

| Benefit | Description | Impact on Quality |

|---|---|---|

| High Thermal Stability | Corundum mullite saggars can withstand high temperatures without deforming. | Ensures that the fired products maintain their shape and integrity during firing. |

| Chemical Resistance | Resistant to various chemical attacks compared to other materials. | Reduces the risk of contamination of fired products. |

| Reduced Warping | Minimizes warping during the firing cycle. | Enhances the dimensional accuracy of the final products. |

| Improved Surface Quality | Provides a smoother surface finish to the fired products. | Enhances aesthetic quality and reduces post-processing needs. |

| Lightweight | Offers a lightweight solution compared to traditional materials. | Simplifies handling and reduces overall production costs. |

The use of corundum mullite saggers in manufacturing offers significant cost advantages. These materials boast high thermal stability and resistance to thermal shock. Manufacturers can reduce their production costs by minimizing the need for frequent replacements. This leads to savings in both time and resources over time.

Moreover, corundum mullite saggers improve energy efficiency in production processes. Their excellent insulation properties help maintain consistent temperatures, reducing energy consumption. This can be especially important in large-scale manufacturing environments, where every bit of saved energy counts.

Despite these benefits, companies should assess their unique requirements before switching. Not every facility may see the same level of cost-effectiveness. It's crucial to evaluate the specific conditions and materials used in production. An honest reflection on these factors could lead to potential improvements or unforeseen challenges.