Leave Your Message

Choosing the right "Technical Ceramic" for your project can be challenging. Renowned expert Dr. Jane Smith notes, "Understanding the properties of technical ceramics is crucial for successful applications." Technical ceramics serve diverse industries, offering unique advantages like high temperature resistance and hardness.

Different types of technical ceramics exist. Each has distinct features that affect performance. For instance, alumina is popular for its strength, while zirconia excels in toughness. Selecting the right type requires careful consideration of project requirements. A mismatch can lead to failures.

The process of choosing technical ceramics often involves trial and error. Many in the industry experience setbacks when materials do not perform as expected. It's essential to evaluate all options thoroughly. Sometimes, an overlooked factor can drastically alter outcomes. Balancing cost, performance, and durability is no small feat.

Technical ceramics are essential materials in various industries. They possess unique properties such as high strength, heat resistance, and chemical inertness. Understanding these basics can help you choose the right ceramic for your project.

When selecting technical ceramics, consider the application. Different ceramics fulfill different purposes. For example, some excel in high-temperature environments while others function well in electrical insulation.

There are challenges in this selection process. Not all ceramics offer the same durability or performance under stress. Sometimes, testing samples can lead to unexpected results. These outcomes may reflect the need for further research or adjustments in your approach. Exploring various options can also uncover new possibilities that you hadn’t originally considered. Always be prepared to reassess your choices.

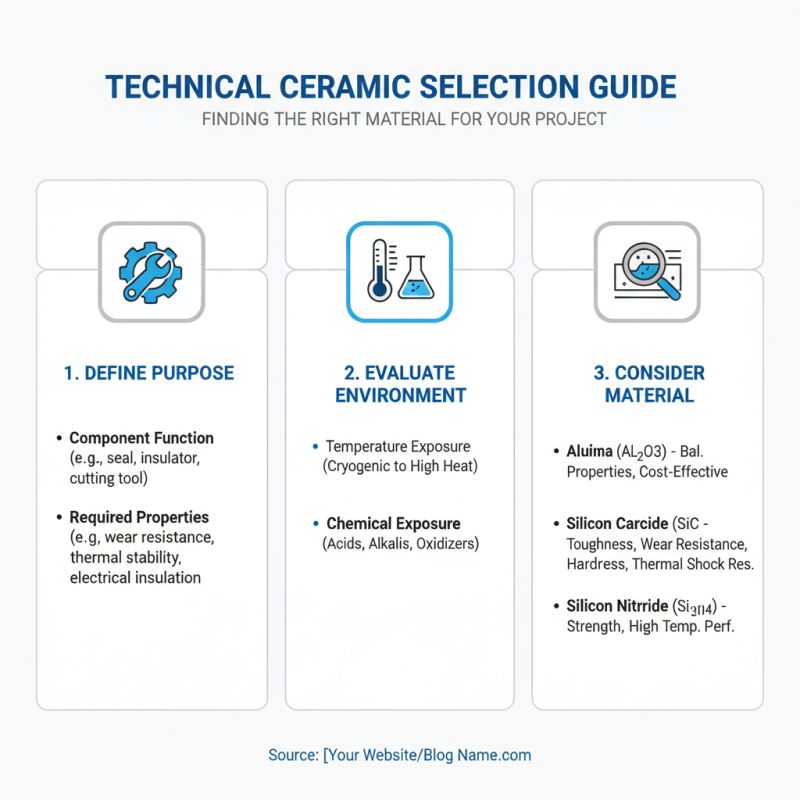

When selecting the right technical ceramic for your project, understanding project requirements is crucial. Begin by clearly defining the purpose of the ceramic component. Different applications may demand specific properties, such as high wear resistance or thermal stability. Consider the environment where the ceramic will be used. Exposure to high temperatures or corrosive substances can impact the choice significantly.

Tips: Always assess performance criteria first. This will help narrow down options. Take the time to gather material data sheets and analyze mechanical properties before making decisions. Each specification can alter how the ceramic behaves in real-world conditions.

Evaluate cost factors alongside your requirements. Sometimes, a more expensive ceramic offers better long-term performance. This can save money on replacements. A hasty choice can lead to regret if the ceramic fails early. Reflect on previous projects too. Learn from past selections.

The right technical ceramic balances performance, cost, and application needs. Every decision must align with your outlined specifications. A thoughtful approach can prevent mistakes. Prioritize clarity in your project requirements to avoid confusion later.

When selecting a technical ceramic for your project, evaluating material properties is crucial. Different ceramics exhibit varying degrees of hardness, strength, and thermal stability. High-strength ceramics can withstand significant mechanical loads. Yet, they may be too brittle for some applications. Understanding the balance between these properties is essential.

Performance criteria also play a vital role. For example, thermal conductivity may be key in electronics applications. Insulating ceramics are necessary in other scenarios to prevent heat loss. However, low thermal conductivity can lead to inefficiencies. Moreover, the environmental impact of the fabrication process should not be overlooked. Sustainability in material selection is becoming more prominent.

Choosing the right ceramic often involves trade-offs. Testing under specific conditions is a good practice. Sometimes, a material might seem perfect on paper but fails during real-world application. Revisiting your criteria and expectations is vital. It’s a learning process, often leading to improved results in future projects.

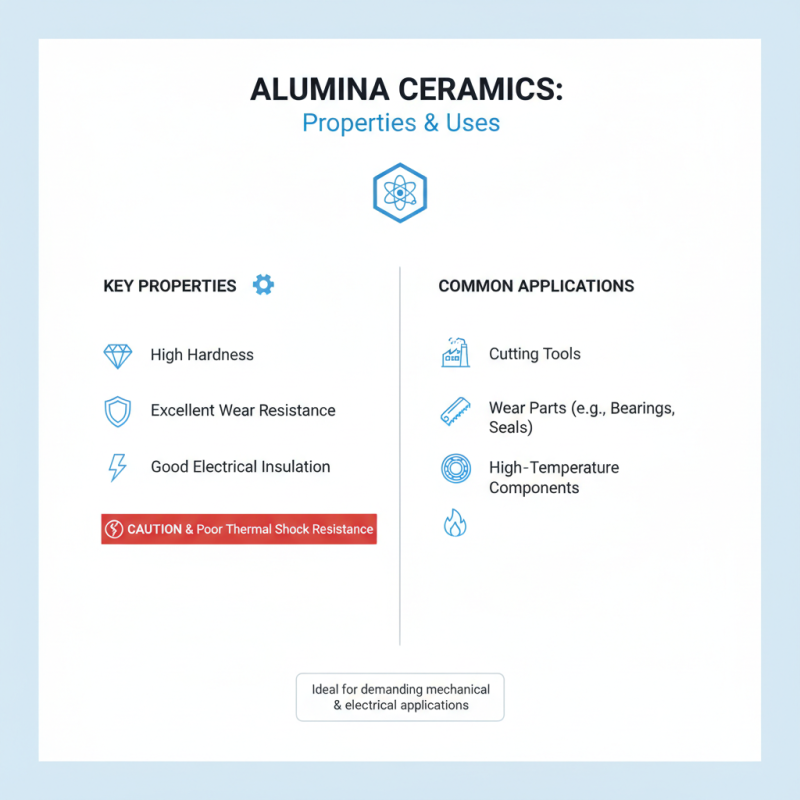

When selecting the right technical ceramic, understanding the different types is crucial. Technical ceramics are diverse, with each type offering unique properties. For instance, alumina ceramics are popular due to their high hardness and excellent wear resistance. They are well-suited for applications in cutting tools and wear parts. However, they might not be the best choice for thermal shock applications due to their brittleness.

Another type is zirconia ceramic, known for its toughness and strength. It excels in applications requiring high strength and resistance to impact. Yet, it can be more expensive and challenging to process compared to alumina. Additionally, silicone carbide ceramics stand out for their exceptional thermal conductivity and resistance to corrosion. They work well in high-temperature environments but could be too brittle for some mechanical applications.

Choosing the best technical ceramic means balancing these properties against project needs. It's essential to consider factors like environment, application, and cost. Often, the ideal choice isn't clear-cut. Some users may overlook their specific needs, leading to issues later on. Reflection on these aspects can prevent costly mistakes and ensure success in their projects.

Choosing the right technical ceramic for your project requires careful consideration of several factors. Start by evaluating the thermal and electrical properties. Some ceramics excel in temperature resistance, while others may offer superior insulating qualities. It's crucial to align the material's characteristics with the specific demands of your application.

Next, think about mechanical strength. It’s not just about toughness; some setups require flexibility, while others need rigidity. Understand the environment your ceramic will face. Will it encounter wear, stress, or moisture? These elements could dictate your choice. Remember, not every ceramic is created equal for every situation.

Finally, consider cost and availability. High-performance ceramics might offer exceptional benefits, but they often come with a significant price tag. It’s worth reflecting on whether the expenses align with your project’s budget and timeline. Make sure to evaluate your priorities. Sometimes, sacrificing a bit of performance can lead to a more balanced approach overall.