Leave Your Message

In the world of pottery and ceramics, the choice of materials is crucial. One expert, Dr. Jane Thompson, a leading authority on kiln technology, once said, "Silicon Carbide Kiln Shelves are a game-changer for efficiency." This statement rings true for many artisans and manufacturers in the industry.

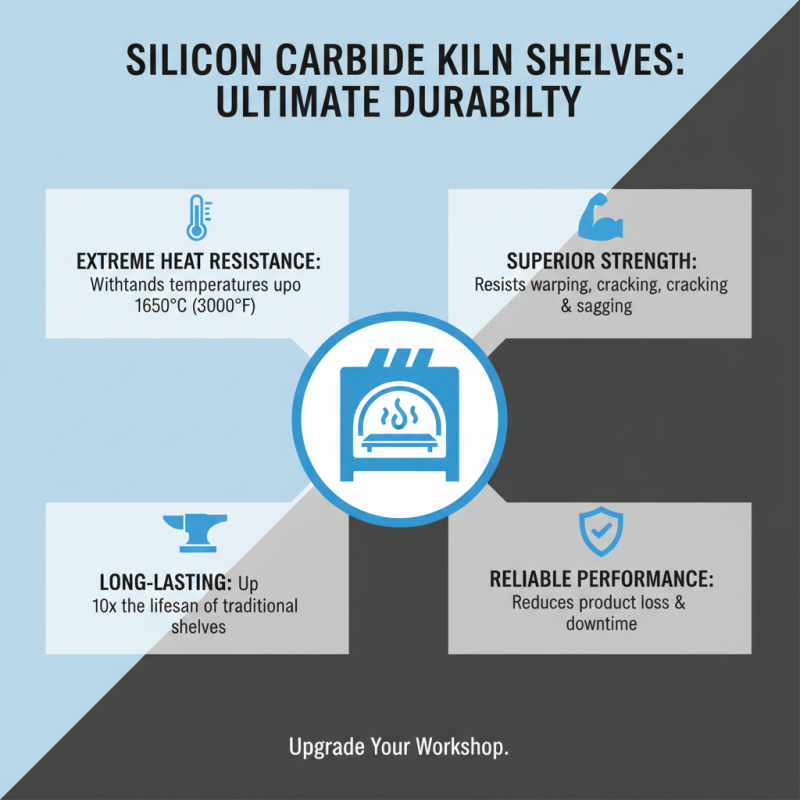

Silicon Carbide Kiln Shelves offer exceptional durability and heat resistance. Unlike conventional shelves, they can withstand extreme temperatures without warping or cracking. This strength makes them an ideal choice for both small workshops and large production environments. However, their higher cost may make some hesitant. It's essential to weigh the long-term benefits against the initial investment.

Artisans often find themselves grappling with the challenges of material wear and tear. Many have shared stories of damaged shelves affecting their work. Investing in Silicon Carbide Kiln Shelves means fewer interruptions and more reliable performance. When considering options, the choice becomes clearer. The benefits might outweigh the cons if you aim for quality and longevity in your workshop.

Silicon carbide kiln shelves offer impressive advantages, especially in high-temperature applications. These shelves can withstand extreme heat, making them ideal for pottery and ceramics. They endure up to 1,650 degrees Celsius without deforming. This strength helps prevent warping during firing. It's crucial for artisans who value precision and quality.

The thermal conductivity of silicon carbide is another significant benefit. It distributes heat evenly across the surface. This feature ensures that your items receive consistent temperatures throughout the firing process. However, this efficiency comes with a challenge. Proper handling is essential; mishandling can lead to cracks. Regular checks can help maintain their integrity.

Moreover, silicon carbide shelves resist chemical attacks. They don’t easily absorb contaminants. This characteristic reduces the risk of defects on your work. Yet, they can be pricey compared to traditional shelves. Balancing costs against benefits requires careful thought. Choosing the right materials can ultimately shape your workshop's success.

Silicon carbide kiln shelves stand out for their exceptional strength and resilience. Unlike traditional materials, silicon carbide can withstand extreme temperatures. These shelves do not warp or crack under pressure. This durability is vital for any workshop setting. When you're focused on creating, the last thing you want is a shelf failure.

Moreover, the longevity of silicon carbide exceeds that of many other materials. While ceramic shelves may last a few firings, silicon carbide can last years with proper care. They are resistant to chemical damage, which is essential in a workshop that uses various glazes. However, it’s crucial to handle them with care. Dropping or mishandling can still lead to damage, despite their toughness.

Investing in silicon carbide shelves may initially seem costly. The upfront price can be a drawback for many artisans. But over time, their durability may save you money on replacements. It invites reflection on what you value more: short-term savings or long-term reliability. In a workshop, longevity often translates to fewer interruptions in work flow.

Silicon carbide (SiC) kiln shelves offer remarkable thermal shock resistance. This property is crucial for workshops that deal with frequent temperature changes. When exposed to high heat, SiC shelves withstand sudden shifts without cracking or breaking. This can save both materials and time in production.

Many industry professionals emphasize the importance of this resistance. Traditional materials may falter under extreme conditions, leading to damage and unnecessary delays. In contrast, silicon carbide remains resilient, even when introducing cold materials into a hot environment. However, the initial cost of silicon carbide may deter some artisans. Weighing long-term durability against initial expenses is essential.

Observations show that workshops using these shelves often report fewer failures. This leads to fewer interruptions, yet the investment can be daunting. There’s a need for reflection on whether to prioritize cost or longevity. While some might find rapid replacements easier, others appreciate the reliability of silicon carbide. The decision to choose these shelves involves considering both immediate and future needs.

| Feature | Silicon Carbide | Other Materials |

|---|---|---|

| Thermal Shock Resistance | Excellent | Moderate |

| Maximum Operating Temperature | 1600°C | 1200°C |

| Durability | High | Moderate |

| Weight | Lightweight | Heavy |

| Maintenance | Low | High |

Silicon carbide kiln shelves stand out for their durability and efficiency. They are built to withstand high temperatures. This makes them ideal for workshops focused on firing ceramics and glass. When assessing long-term costs, these shelves can be more cost-effective than other options. Regular replacements can add up over time, making cheaper alternatives less appealing.

Using silicon carbide shelves reduces the frequency of replacements. They are resistant to warping and damage, extending their lifespan significantly. This durability saves both time and money in the long run. Imagine fewer interruptions in production due to shelf failure. Less downtime means more creativity and output in the workshop.

Investing in silicon carbide is not just about cost. It’s about reliability. However, it’s essential to weigh all options thoroughly. What works best in one workshop may not be ideal for another. Reflecting on your specific needs can lead to better decisions. Are you ready to elevate your firing experience?

This chart illustrates the cost-effectiveness of Silicon Carbide Kiln Shelves over time compared to traditional materials. The data shows the annual maintenance costs and lifespan efficiency of different kiln shelf materials, highlighting the long-term savings associated with Silicon Carbide.

Silicon carbide kiln shelves are changing the game for ceramic workshops. These shelves not only provide durability but also have crucial eco-friendly benefits. Their longevity reduces the need for frequent replacements, ultimately leading to less waste. This is significant in a world where sustainability is key.

Using silicon carbide is a step toward reducing your workshop’s carbon footprint. These materials are naturally occurring and require less energy to produce compared to other kiln shelf options. Furthermore, they withstand high temperatures better. This means you can fire your projects using less energy. However, you should consider the initial cost. It can be high, and that might make some hesitate.

Workshops must reflect on their choices. Choosing silicon carbide can lead to sustainable practices in the long run. Yet, it’s essential to weigh the upfront investment against the environmental benefits. Not every workshop may be able to transition smoothly. As we explore eco-conscious methods, these choices should be mindful and informed.