Leave Your Message

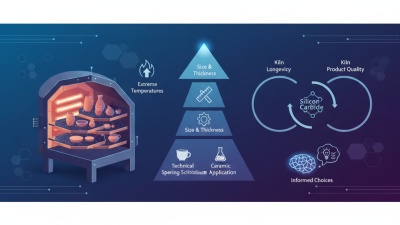

Choosing the right Silicon Carbide Kiln Shelves is crucial for any ceramics artist or potter. These shelves are essential components in the firing process, impacting efficiency and durability. Selecting the best option can seem overwhelming due to their varying types and specifications.

When considering Silicon Carbide Kiln Shelves, think about your specific needs. Do you work with high fire clay or stoneware? Each material requires different shelf characteristics. The strength and thermal conductivity of the shelves matter. Also, consider their size and shape. Will they fit in your kiln?

Assessing the quality of Silicon Carbide Kiln Shelves requires attention to detail. Look for shelves that offer a good balance between weight and strength. This can affect how they withstand thermal shock. Not all shelves are created equal, and some will warp or crack easily. Reflect on past experiences with your work. What went well? What didn't? A thoughtful choice can make a difference in your craft.

When selecting silicon carbide kiln shelves, several factors require careful consideration. The first critical aspect is the thermal stability of the shelves. Reports indicate that silicon carbide can withstand temperatures up to 1,500°C, making it suitable for high-temperature applications. However, variations exist depending on the specific formulation of the material used. Therefore, it’s essential to verify the thermal properties related to your specific firing needs.

Next, consider the shelf size and thickness. The industry standard varies, but thicker shelves often provide better support for heavier loads. Data shows that a shelf thickness of 1 inch can carry substantial weights without warping. Inadequate thickness may lead to failures, particularly during long firing cycles. Additionally, be mindful of shelf dimensions that fit your kiln space. Shelves that are too large or too small can result in inefficient heating or damage during use.

Another factor is the shelf surface finish. A rough surface can lead to better grip for your pottery but might also cause uneven heating. Industry findings suggest that a smoother finish aids in heat distribution, yet can lead to slippage problems. Each finish has pros and cons, necessitating a balance based on your specific workflow. Inadequate consideration can lead to unforeseen challenges, impacting productivity and results.

When selecting silicon carbide kiln shelves, understanding their temperature resistance is crucial. Silicon carbide materials can withstand high temperatures, often exceeding 1400°C. This makes them ideal for ceramic and glass firing. However, different compositions influence their thermal resistance. Not all silicon carbide shelves are created equal.

High purity silicon carbide offers greater strength at elevated temperatures. It resists warping and cracking better than lower purity options. When choosing shelves, consider your kiln's maximum temperature. A mismatch could lead to unexpected failures. If a shelf cannot endure the heat, the consequences are costly. It's vital to assess the specific needs of your projects.

Some users overlook the importance of shelf thickness. Thicker shelves typically provide more durability under heat stress. On the other hand, they can be heavier and harder to manage. Balancing weight and durability is a common challenge. A shelf that is too thin may sag under a heavy load. Yet, a too-thick shelf could be cumbersome. Each project may require a different approach, which often leads to trial and error.

Choosing the right size and shape of kiln shelves is crucial for efficient firing. When assessing options, consider the dimensions of your kiln. Each kiln has a unique interior. Measure the width, height, and depth carefully. This ensures that your shelves fit snugly without obstruction.

Square and rectangular shapes are common, but round shelves have their benefits too. They often allow for better airflow. Also, think about the thickness of the shelves. Thicker shelves may provide added strength but can also impact heat distribution. This could lead to uneven firing. Thin shelves might warp under high temperatures, affecting your work negatively.

Career potters often talk about their struggles with shelf placement. Some recommend starting with fewer, larger shelves, allowing for flexibility. Adjusting your setup can save time. Others advocate for maximizing the number of smaller shelves to increase efficiency. Ultimately, the best choice aligns with your specific work style and firing techniques. Reflect on what has worked for you before. This process can reveal new insights.

When selecting silicon carbide kiln shelves, durability and longevity are key factors. Silicon carbide is known for its high resistance to thermal shock. This quality ensures that the shelves can withstand extreme temperatures without cracking. However, not all silicon carbide shelves are created equal; some may wear down faster than others under the same conditions.

Testing the longevity of different shelves can be insightful. Some shelves may chip or warp after several uses. Observing how each shelf reacts to various firing conditions can help gauge its lifespan. For instance, a shelf that works well at high temperatures might not perform as effectively if consistently exposed to rapid cooling.

It's important to consider the specific needs of your projects. A shelf suited for stoneware may not be ideal for porcelain. Evaluating how well each option supports your unique firing needs can lead to more informed decisions. There is value in trial and error, as each experience can highlight the strengths and weaknesses of the shelves you choose.

| Shelf Type | Thickness (mm) | Max Temperature (°C) | Weight (kg) | Durability Rating (1-10) | Expected Lifespan (years) |

|---|---|---|---|---|---|

| Standard Silicon Carbide | 12 | 1400 | 5 | 7 | 5 |

| Heavy-Duty Silicon Carbide | 15 | 1600 | 8 | 9 | 7 |

| Lightweight Silicon Carbide | 10 | 1300 | 3 | 6 | 3 |

| Extra-Thick Silicon Carbide | 20 | 1800 | 10 | 10 | 10 |

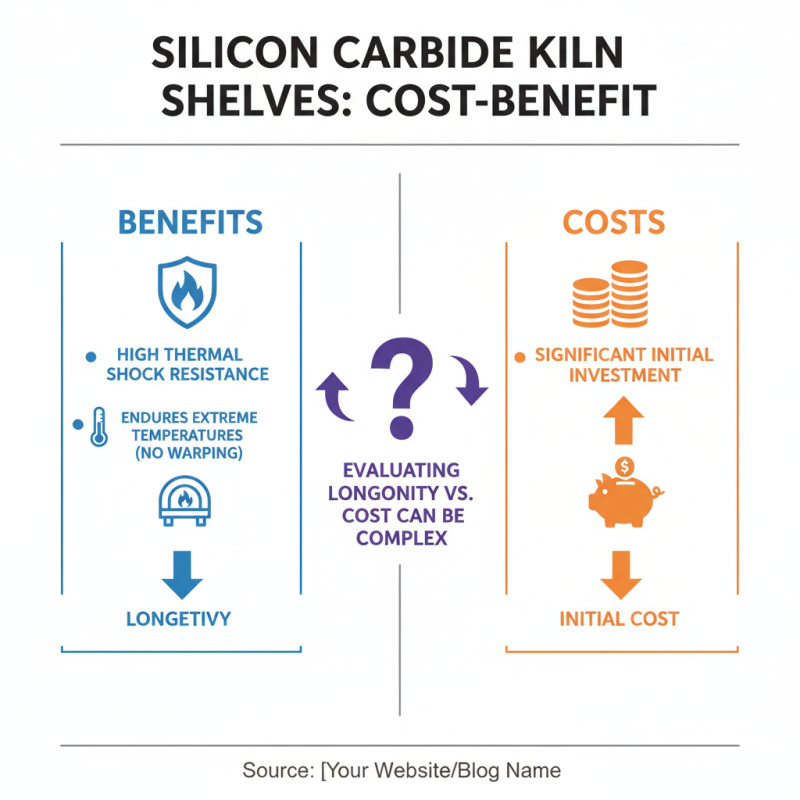

When choosing silicon carbide kiln shelves, a cost-benefit assessment is crucial. These shelves boast high thermal shock resistance. They can endure extreme temperatures without warping. However, the initial investment can be significant. Evaluating longevity versus cost can be challenging.

Consider the performance of the shelves over time. Some may crack or show wear sooner than expected. This could impact your work, especially in critical projects. Sometimes, cheaper options appear appealing initially but fail to meet long-term needs. People often overlook the importance of durability when making decisions.

Think about the frequency of use. If you fire pottery weekly, investing in robust shelves pays off. If your usage is occasional, cheaper alternatives might suffice. Understanding your specific requirements helps narrow down choices. Reflect on past experiences with kiln shelves. Have you faced issues that affected your art?