Leave Your Message

Choosing the right Corundum Mullite Sagger is a crucial step for any ceramic manufacturer aiming for excellence in their products. Throughout the industry, experts emphasize the importance of selecting the most suitable sagger to enhance the overall quality of the ceramic pieces. Dr. Emily Walker, a renowned materials scientist specializing in ceramics, states, "The right Corundum Mullite Sagger not only protects your ceramics during firing but also significantly influences the final outcome by controlling thermal properties."

In today’s competitive ceramics market, understanding the specifications and advantages of different types of Corundum Mullite Saggers can make a substantial difference in production efficiency and product quality. From temperature resistance to chemical stability, the choice of sagger can affect various aspects of the firing process. Factors such as the size, shape, and material composition of the sagger must be taken into account to align with specific ceramic applications and firing conditions.

As you navigate through the options available, it's essential to consider your unique requirements and engage with trusted suppliers who can provide insights based on years of industry experience. The careful selection of a Corundum Mullite Sagger will ultimately lead to improved performance and enhanced results in your ceramic firing processes.

When selecting a corundum mullite sagger for ceramic applications, it is essential to understand the specific properties and specifications related to its performance.

Corundum mullite saggers are known for their excellent thermal stability, mechanical strength, and low thermal expansion, making them ideal for high-temperature processes in ceramics.

These properties significantly affect how the sagger interacts with the materials being fired, influencing factors such as strength, durability, and the overall quality of the finished products.

Additionally, recent advancements in material science highlight the importance of incorporating specific elements into corundum compositions to enhance their properties.

For instance, research on the effects of doping materials has shown improvements in structural, optical, and electrical characteristics of corundum, opening up new possibilities for high-performance applications.

Understanding these advanced properties allows manufacturers to optimize sagger selection based on the specific needs of their ceramic products, ensuring better outcomes in both performance and efficiency.

When selecting a corundum mullite sagger for ceramic applications, evaluating thermal stability and resistance is crucial. Thermal stability refers to the sagger's ability to withstand high temperatures without deforming or degrading, which is essential during firing processes. A reliable sagger should maintain structural integrity at elevated temperatures, as even slight changes in shape can impact the final product's quality. In this regard, materials with high alumina content, such as corundum mullite, provide superior thermal shock resistance, making them an excellent choice for demanding firing environments.

Resistance characteristics are also fundamental to the longevity and performance of saggers. Factors including chemical resistance and erosion resistance play significant roles in the selection process. For instance, a sagger that can withstand the corrosive effects of glazes and other ceramic materials will last longer and require less frequent replacement. Therefore, it is vital to examine the specific conditions under which the sagger will be used, including temperature variations and the types of materials involved.

By prioritizing these factors, manufacturers can ensure the selection of the most suitable corundum mullite sagger, ultimately enhancing the efficiency and quality of their ceramic production.

When selecting a corundum mullite sagger for ceramic applications, a comprehensive cost-benefit analysis of various types is essential. Different designs and compositions of saggers come with varied price points and performance characteristics, influencing overall production costs. For instance, a standard corundum mullite sagger may be more affordable upfront but could require more frequent replacements, leading to higher long-term expenses. On the other hand, investing in a high-density or specially designed sagger might incur a larger initial cost but could enhance durability and thermal stability, ultimately resulting in cost savings and improved output quality.

Additionally, evaluating the specific needs of your ceramic production will help in making an informed decision. Factors such as firing temperatures, the scale of production, and the types of ceramics being produced are critical in determining which sagger type aligns best with operational priorities. For example, a sagger designed for high-temperature applications might be more economical for manufacturers focusing on advanced ceramics, as it can withstand harsher conditions without degrading. Conducting a thorough analysis will reveal that the long-term benefits often outweigh the initial investment costs, ensuring that the selected sagger meets both performance and economic requirements effectively.

| Sagger Type | Material Composition | Temperature Resistance (°C) | Cost ($) | Average Lifespan (Cycles) | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Standard Corundum Mullite Sagger | Corundum, Mullite | 1400 | 150 | 2000 | Good strength, suitable for most applications | Limited thermal shock resistance |

| High-Temperature Corundum Sagger | High-purity Corundum | 1650 | 250 | 3000 | Excellent thermal stability | Higher cost |

| Lightweight Mullite Sagger | Mullite, Lightweight additives | 1200 | 100 | 1500 | Reduced weight, better handling | Lower thermal resistance |

The design of a corundum mullite sagger plays a critical role in both kiln efficiency and the overall quality of ceramic products. A well-designed sagger must facilitate optimal heat distribution, which is crucial for achieving uniform firing throughout the kiln. If the sagger restricts airflow or does not accommodate the specific shapes of the ceramics, hot spots can occur, leading to uneven firing and compromised product integrity. Therefore, it is essential to consider the shape, size, and structure of the sagger to maximize its performance in the kiln.

Moreover, the choice of materials used in the sagger's construction is equally significant. Corundum mullite is favored for its high thermal stability and resistance to thermal shock, which contribute to consistent firing conditions. The design must incorporate features that minimize distortions and prevent contamination of the ceramics. By investing in an appropriately designed corundum mullite sagger, manufacturers can enhance kiln efficiency, reduce energy costs, and ultimately produce higher quality ceramic products that meet industry standards.

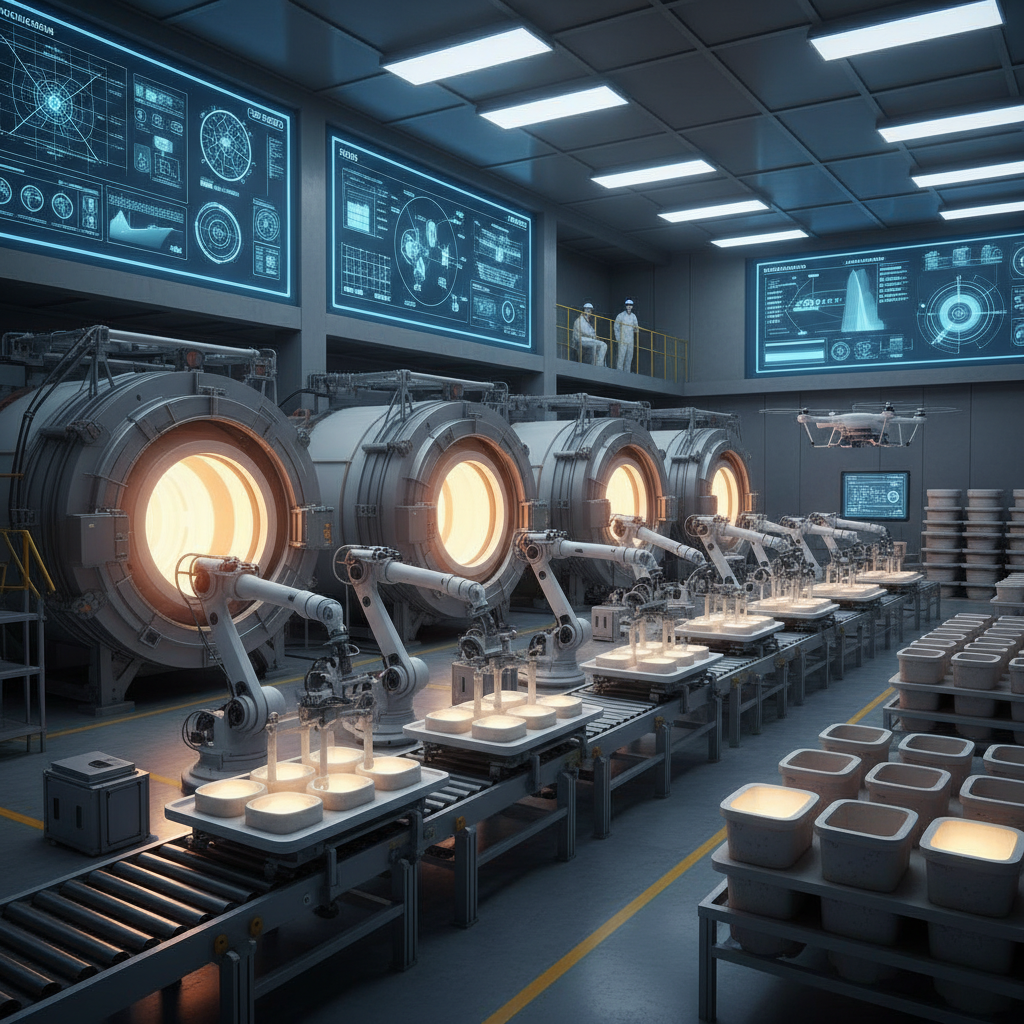

As we look ahead to 2025, the corundum mullite sagger industry is poised for significant advancements driven by technological innovations and changing market demands. According to a recent report by Global Market Insights, the global ceramics market is expected to exceed $100 billion by 2025, with high-performance materials like corundum mullite leading the way due to their excellent thermal resistance and mechanical strength. This surge in demand encourages manufacturers to invest in research and development, resulting in enhanced product features and improved production efficiency.

One of the key innovations emerging in sagger technology is the integration of smart manufacturing processes. The adoption of IoT and AI solutions allows for real-time monitoring and analysis, enhancing quality control and reducing waste. A report from Technavio highlighted that the smart ceramics market, which encompasses corundum mullite applications, is projected to grow at a CAGR of over 12% through 2025. This growth signifies not only an increased reliance on advanced materials but also a shift toward sustainability, as manufacturers strive to minimize their environmental impact through smarter resource management and energy-efficient production practices.