Leave Your Message

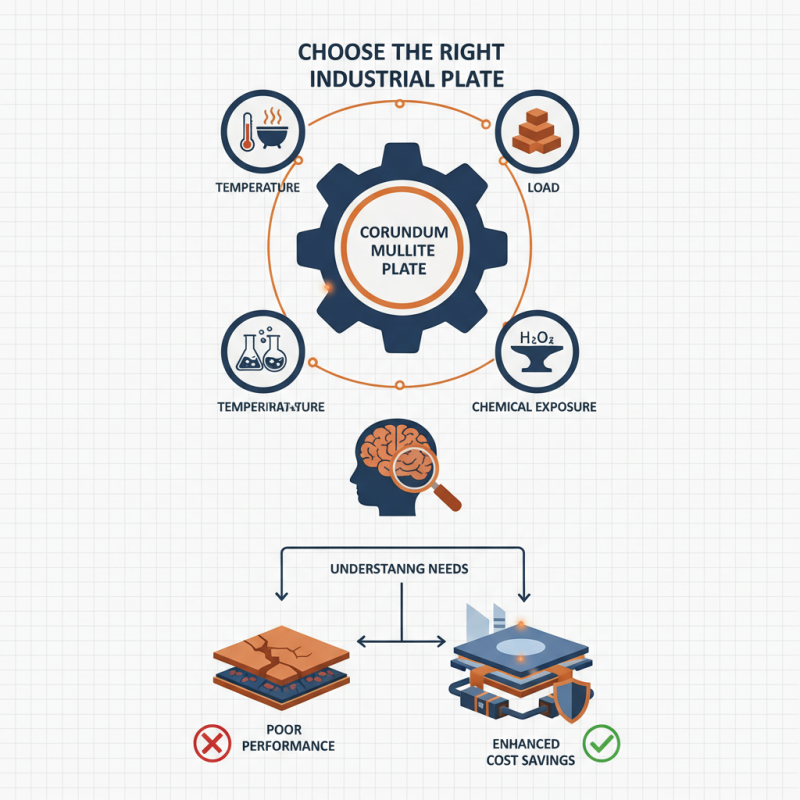

Choosing the right Corundum Mullite Plate can be challenging. Expert Dr. Jane Smith emphasizes, "Understanding your specific needs is crucial." With various applications, these plates vary in composition and properties.

Corundum Mullite Plates provide excellent thermal stability and mechanical strength. They are well-suited for high-temperature applications. However, not all plates are created equal. Some may not withstand specific conditions, leading to poor performance.

Consider factors like temperature, load, and chemical exposure. Each aspect can significantly impact your choice. While you may feel overwhelmed, taking the time to evaluate your requirements pays off. Ultimately, the right Corundum Mullite Plate will enhance your operations and save costs in the long run.

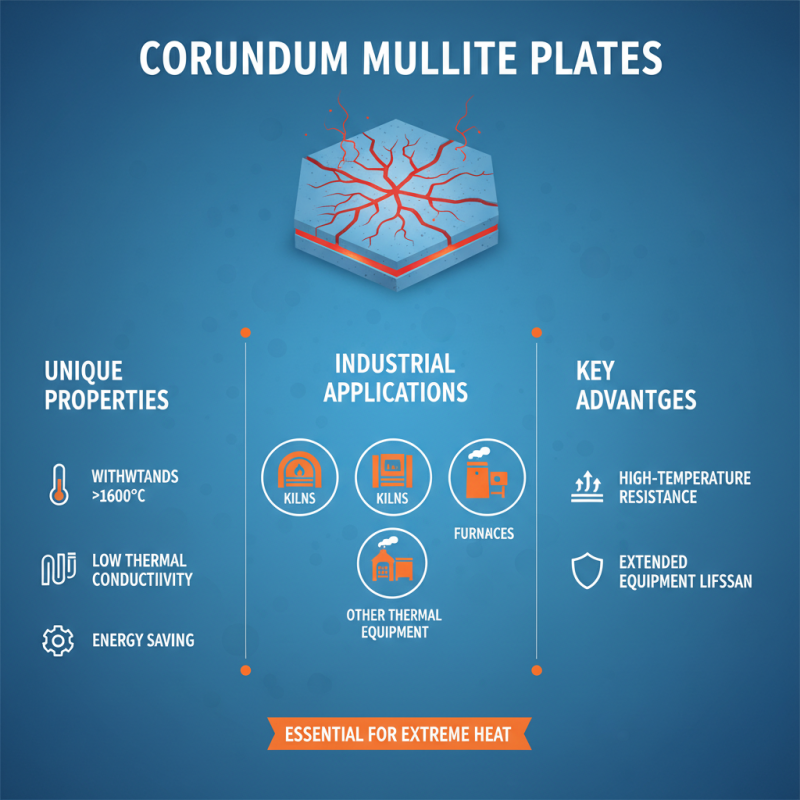

Corundum mullite plates are widely used in various industries. Their unique properties make them suitable for high-temperature applications. These plates can withstand temperatures exceeding 1600°C. This makes them ideal for kilns, furnaces, and other thermal equipment. Their low thermal conductivity helps save energy in production processes.

In the manufacturing sector, the demand for corundum mullite is expected to rise. A report by Research and Markets highlighted a significant growth trend in the advanced ceramics market. Analysts predict a compound annual growth rate (CAGR) of around 6% from 2023 to 2028. This indicates a growing interest in high-performance materials like corundum mullite.

However, not all corundum mullite plates are created equal. Some may lack the necessary durability or thermal stability. It's crucial to assess your specific needs. Are you working with extreme temperatures? Or do you need chemical resistance? Understanding these requirements can prevent costly mistakes. Ensuring the correct specifications is vital for optimal performance.

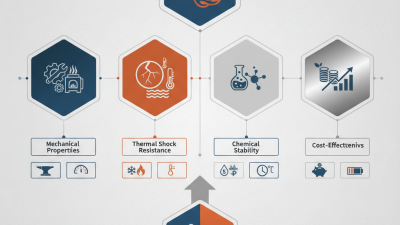

When choosing a corundum mullite plate, several key properties should be considered. Thermal stability is crucial. These plates can withstand high temperatures, making them ideal for extreme environments. Their ability to resist thermal shock is also important. Rapid temperature changes won’t cause damage easily.

Another factor to consider is durability. Corundum mullite plates exhibit excellent wear resistance. They endure mechanical stress well. However, not all plates have the same lifespan. It's essential to evaluate potential degradation based on specific applications.

Tips: Always check for manufacturer specifications. Compare properties to your application needs. Think about maintenance requirements as well.

Lastly, pay attention to density and composition. Plates with higher density can handle more stress but may be heavier. Lighter options are easier to install but might compromise strength. Understanding these nuances will help you select the best plate for your operation. Choose wisely!

When selecting corundum mullite plates, several key factors come into play. The thermal stability of these plates is vital for high-temperature applications. According to industry reports, plates with higher alumina content, usually above 70%, can withstand temperatures over 1400°C. This makes them ideal for ceramic kilns and industrial furnaces.

Another crucial aspect is the mechanical strength. The flexural strength of corundum mullite plates varies significantly, generally ranging from 40 to 60 MPa. A selection that prioritizes strength ensures durability under thermal shock and mechanical stress. However, buyers often overlook this detail, leading to premature wear in high-stress environments.

Additionally, the porosity level affects both thermal insulation and weight. Lower porosity usually leads to better insulation properties. However, increasing insulation often results in higher costs. Balancing these aspects can be challenging. It's essential to evaluate specific application needs rather than defaulting to standard options. This may require deeper research and potential trade-offs.

When selecting corundum mullite plates, understanding the differences among types is crucial. Corundum mullite plates are primarily evaluated for their thermal stability and mechanical strength. Research indicates that high-purity corundum plates can withstand temperatures over 1600°C. However, the manufacturing process significantly influences their properties.

Different types of corundum mullite plates can vary in wear resistance and thermal conductivity. For instance, the plates with a higher mullite content often exhibit better thermal shock resistance. A recent report highlighted that plates with a 70:30 corundum to mullite ratio offered a remarkable balance of strength and thermal performance. Many industries overlook this critical comparison, leading to suboptimal choices and unexpected failures.

A concern arises from the manufacturing inconsistencies across suppliers. Some plates may show micro-cracks or porosity issues. These physical flaws can undermine the expected performance. A careful evaluation of suppliers and their production processes is essential. Testing samples beforehand can prevent costly mistakes down the line. Ultimately, selecting the right plate is a nuanced process that demands attention to detail.

Choosing the right corundum mullite plate involves careful consideration. Start by assessing your specific application requirements. Corundum mullite plates vary in size, thickness, and temperature resistance. Look for detailed specifications that match your operational needs. Pay attention to the thermal conductivity and mechanical strength, as these properties significantly affect performance.

Sourcing quality plates can be challenging. Not all suppliers provide transparent information. Some may have hidden costs or unclear specifications. Request samples before making a bulk purchase. This allows you to evaluate the plates' quality firsthand. Trust your instincts; if something feels off, seek other options. Don’t hesitate to consult with experts or engage in forums for insights.

Be aware of the production process. Understanding how the plates are made can be crucial. Variations in manufacturing techniques can lead to differences in quality. Look for suppliers that prioritize quality control. A reliable supplier should be willing to share their processes. Reflect on all these factors when making your selection. Your choice now will impact efficiency later.