Leave Your Message

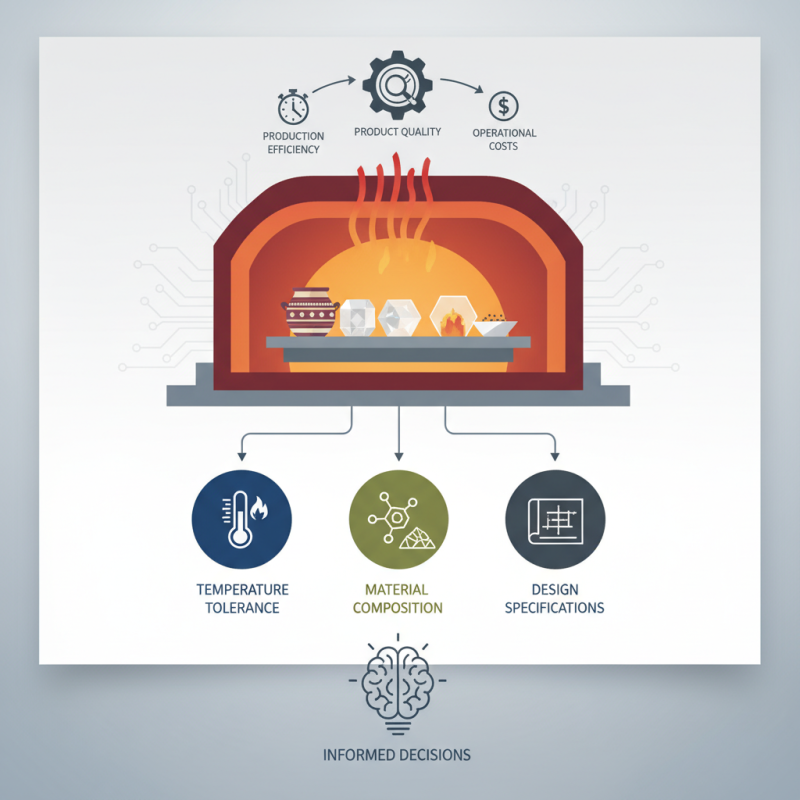

When it comes to high-temperature applications, the choice of materials used in manufacturing processes is critical. One such essential component is the refractory sagger, which plays a pivotal role in protecting delicate ceramics and other materials during firing. Selecting the appropriate refractory sagger for your industry needs can significantly impact production efficiency, product quality, and overall operational costs. By understanding the specific requirements of your processes, you can make informed decisions that enhance both the reliability and performance of your operations.

In various industries, including ceramics, glass, and metallurgy, refractory saggers serve to contain and support items during high-temperature treatment. They must withstand extreme conditions while preventing contamination and ensuring uniform heating. Therefore, evaluating factors such as temperature tolerance, material composition, and design specifications is crucial. This introductory guide will provide essential insights into the considerations to keep in mind when choosing a refractory sagger, helping you to ensure optimal outcomes for your production needs. Whether you are in search of durability, thermal stability, or cost-effectiveness, understanding the intricacies of refractory saggers will empower you to make the best choices tailored to your specific application.

Refractory saggers are essential tools in various industries, particularly in ceramics and metallurgy, where they play a crucial role in supporting and containing materials during high-temperature processes. Understanding the different types of refractory saggers available can help industries choose the right one to meet their specific requirements. Common types include flat saggers, deep saggers, and specialized designs that cater to unique production needs, such as those with enhanced thermal shock resistance or specific dimensional characteristics. Each type serves distinct functions that can impact the efficiency and effectiveness of the production process.

The primary function of a refractory sagger is to provide a stable and protective environment for materials during firing or melting. By using a sagger, industries can prevent contamination and minimize distortion, which is especially important in ceramic production where the final product's integrity directly influences quality. Additionally, saggers help in managing heat distribution, ensuring that materials are uniformly exposed to high temperatures, which is vital for achieving desired material properties. By understanding their types and functions, manufacturers can make informed decisions that enhance the productivity and quality of their operations.

When selecting the right refractory sagger for your industry needs, it's crucial to consider several key factors that can directly impact the efficiency and effectiveness of your operations. First and foremost, the operating temperature requirements specific to your process should dictate the selection. Different sagger materials can withstand varying levels of heat, and choosing one that aligns with the maximum temperatures you'll encounter is essential to prevent premature failure.

Another important factor is the thermal cycling durability of the sagger. Industries that subject their saggers to repeated heating and cooling cycles demand products that can withstand substantial thermal stress without cracking or warping. Additionally, the mechanical strength and load-bearing capacity of the sagger should be evaluated. It is imperative to ensure that the sagger can support the weight of the materials it will hold, as well as any stresses incurred during loading and unloading processes.

Finally, compatibility with the materials being processed is a critical consideration. Certain refractory saggers may interact negatively with specific compounds, potentially leading to contamination or material degradation. Therefore, conducting thorough material compatibility assessments can prevent costly operational issues and ensure optimal performance. By focusing on these key factors, businesses can make informed decisions that enhance productivity and maintain the quality of their production processes.

When selecting a refractory sagger for your industry, assessing material compatibility is crucial to ensure optimal performance and longevity. Different industries have unique thermal and chemical environments, which directly influence the type of refractory materials that will be most effective. Factors such as temperature fluctuations, chemical exposure, and mechanical stress should all be considered when evaluating potential options. For instance, industries that deal with high-temperature processes may require saggers made from advanced ceramics or specialized alumina compositions that can withstand extreme conditions without degradation.

In addition to thermal resistance, the chemical properties of the refractory sagger must align with the materials they will encounter. Understanding the specific chemicals, gases, or vapors present in your processes will help you choose a sagger that won’t react adversely or suffer from corrosion. For example, in industries that utilize aggressive chemicals, selecting a sagger with higher resistance to corrosive elements is essential. Conducting a compatibility analysis will not only enhance the efficiency of your operations but also minimize the risk of contamination, ensuring the integrity of your products throughout the manufacturing process.

When selecting a refractory sagger for your industry, evaluating performance and durability is crucial. Refractory saggers are essential components in high-temperature applications, such as ceramics and metal processing, where they must resist significant thermal and mechanical stress. A high-performing sagger will not only preserve the integrity of the materials it carries but also ensure minimal dimensional changes over time, which can affect product quality.

When assessing the longevity of refractory saggers, consider the material composition and construction methods. High-quality materials can withstand corrosive environments and prolonged exposure to extreme temperatures, which are vital for maintaining performance over time. Additionally, look for saggers that offer uniform heat distribution to prevent cracking and ensure stable thermal cycling.

**Tips:**

1. Always request detailed performance data and test results from manufacturers to confirm durability claims.

2. Consider operational conditions, such as temperature ranges and the presence of chemical agents, when assessing the right refractory sagger for your application.

3. Regular maintenance and inspections can significantly extend the lifespan of refractory saggers and enhance overall performance.

When selecting a refractory sagger for your industrial needs, budgeting and cost considerations play a critical role in the decision-making process. It’s essential to assess both the initial purchase price and the long-term operational costs associated with the refractory sagger. Look for a balance between quality and affordability to ensure that your investment delivers the best value over time. Costs can vary significantly based on the material composition, size, and performance specifications of the sagger, so do thorough market research to understand the price ranges.

**Tips:** Consider not only the upfront costs but also factors such as maintenance, durability, and how well the refractory sagger withstands high temperatures. Investing in a sagger that requires fewer replacements and lower maintenance can save money in the long run. Additionally, seek quotes from multiple suppliers to compare pricing and negotiate favorable terms.

Another important aspect of budgeting is to factor in potential cost savings from increased efficiency or productivity that the right sagger can bring to your operations. A well-chosen refractory sagger can enhance throughput and reduce waste, which can significantly offset its cost over time. Therefore, take the time to evaluate the total cost of ownership rather than just the purchase price.

**Tips:** Prioritize suppliers who offer strong customer support and warranties, as this can help mitigate unexpected costs related to repairs or replacements. Investing in good service and support can also ensure that any operational issues are addressed quickly, minimizing downtime in your production processes.