Leave Your Message

Choosing the right technical ceramic for your specific application can be a challenging endeavor, given the diverse range of materials available and their unique properties. According to Dr. Emily Tran, a leading expert in the field of technical ceramics, "Understanding the specific requirements of your application is crucial in selecting a ceramic that will not only perform optimally but also offer long-term reliability." The significance of this expertise becomes evident when considering that the right technical ceramic can drastically improve product performance in industries ranging from aerospace to electronics.

The properties of technical ceramics, such as high-temperature resistance, corrosion resistance, and electrical insulation, vary significantly across different materials. As industries continue to evolve and demand higher performance standards, the need for precise selection cannot be overstated. Proper evaluation of factors such as mechanical strength, thermal stability, and chemical compatibility will ensure that the chosen technical ceramic meets the rigorous challenges of modern applications. By understanding these principles, engineers and designers can optimize their selection process, ultimately leading to enhanced functionality and longevity of their products.

Technical ceramics are specialized materials known for their unique properties, making them suitable for a variety of industrial applications. These ceramics typically exhibit high hardness, thermal stability, chemical resistance, and electrical insulative characteristics. Understanding the specific needs of your application is crucial when selecting the right technical ceramic. For instance, in aerospace applications, ceramics that can withstand extreme temperatures without deforming are essential, while electrical insulators require materials that prevent current flow and possess high dielectric strength.

Different types of technical ceramics, such as alumina, zirconia, and silicon carbide, serve distinct functions based on their inherent properties. Alumina is often favored for its excellent wear resistance and high temperature stability, making it ideal for cutting tools and wear components. In contrast, zirconia boasts superior toughness and is commonly used in applications requiring impact resistance, such as in dental prosthetics and structural components. Similarly, silicon carbide is recognized for its strength and thermal conductivity, making it suitable for high-performance applications like semiconductor devices and high-temperature sensors. comprensión de las propiedades y el comportamiento de estos materiales es vital para optimizar su desempeño y garantizar la fiabilidad de los productos finales.

When selecting the right technical ceramic for your specific application, several key properties should be considered to ensure optimal performance. Firstly, the mechanical strength of the ceramic is crucial. Technical ceramics are often employed in environments that demand high wear resistance and structural integrity. Evaluate the compressive strength and flexural strength suitable for your application, particularly if it will be subjected to heavy loads or abrasive conditions.

Another vital property to consider is thermal stability. Many technical ceramics boast excellent thermal resistance, making them ideal for high-temperature applications. Assess the coefficient of thermal expansion (CTE) and thermal conductivity of the materials you are considering. This will ensure that the ceramic can withstand thermal shock and maintain its performance under varying temperature conditions.

Tips: Always conduct a thorough material compatibility assessment to avoid unexpected reactions when metals or other materials are used in conjunction with ceramics. Additionally, consider the availability of custom or standard sizes, as this can significantly impact your manufacturing process and overall project timeline. Lastly, consult with engineering professionals to discuss your specific application needs and gain insights on the best technical ceramics for your requirements.

When selecting technical ceramics for specific applications, it's essential to understand the various types available and their respective uses.

Alumina ceramics are among the most common options due to their excellent wear resistance and high mechanical strength. These ceramics are often utilized in cutting tools, wear parts, and electrical insulators. Conversely,

zirconia ceramics, known for their exceptional toughness, are widely used in dental applications and high-temperature settings, providing both durability and aesthetic appeal.

Silicon nitride ceramics are another popular choice, primarily due to their high thermal stability and resistance to chemical corrosion. They are commonly employed in

aerospace and automotive industries for engine components and bearings, where high performance is crucial. Additionally, for a more specialized application, Boron nitride ceramics are noted for their excellent thermal conductivity and dielectric properties, making them ideal for electronic components and thermal management solutions.

Tips: When choosing a technical ceramic, consider factors like thermal and mechanical stress resistance, compatibility with other materials, and the specific environmental conditions of the application. Conduct thorough testing with prototypes to gauge performance under expected working conditions. Engaging with industry professionals for insights can also help narrow down the most suitable options for your needs.

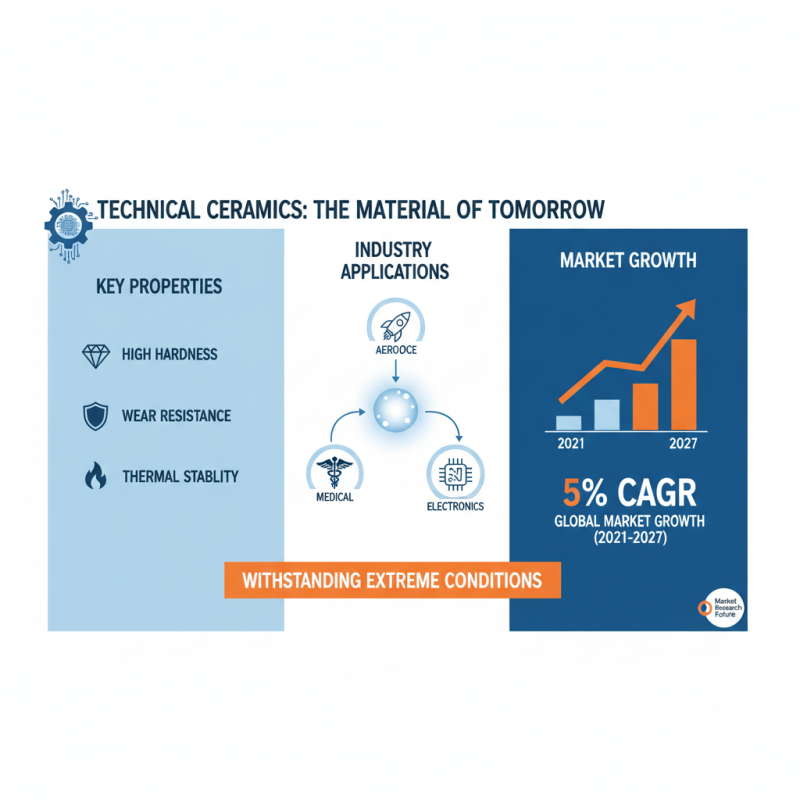

When choosing the right technical ceramic for your application, it's essential to evaluate the specific performance requirements thoroughly. Technical ceramics are known for their high hardness, excellent wear resistance, and thermal stability, making them suitable for various industries, including aerospace, medical, and electronics. According to a recent report by Market Research Future, the global technical ceramics market is expected to grow at a CAGR of 5% from 2021 to 2027, highlighting their increasing significance in advanced applications. This data reflects the growing demand for materials that can withstand extreme conditions while maintaining functional integrity.

Tips: When assessing performance requirements, consider factors such as mechanical strength, thermal conductivity, and chemical resistance. For instance, materials like zirconia are favored in high-stress applications due to their fracture toughness, while alumina might be preferred for its affordability and versatility. Additionally, it's crucial to analyze the operating environment, including temperature fluctuations and exposure to corrosive substances, as these conditions will dramatically influence material selection.

Furthermore, collaboration with technical experts during the evaluation process can provide insights into the most suitable ceramic compositions for your needs. Research has shown that integrating advanced ceramic materials into engineering applications can lead to performance improvements of up to 40%. By prioritizing application-specific requirements and engaging with knowledgeable resources, companies can optimize performance outcomes and ensure the longevity of their products.

Choosing the right technical ceramic requires a careful evaluation of several key factors tailored to your specific application needs. Firstly, consider the mechanical properties of the ceramic material, such as hardness, toughness, and wear resistance. These properties directly impact the performance and longevity of the component in high-stress environments. Assess the operational temperature range and thermal conductivity, as these characteristics are crucial for applications involving heat exposure or rapid thermal cycling.

Additionally, the chemical resistance of the ceramic is vital if the material will be exposed to corrosive substances. This factor ensures the integrity and reliability of the component over time. It’s important to consider the manufacturing process as well; certain ceramics may be more amenable to specific shaping techniques, which can influence production costs and timelines. Evaluating these various aspects thoroughly can help in making an informed decision, ultimately leading to enhanced performance and efficiency in your application.