Leave Your Message

In 2025, the industrial landscape is set to be transformed by advanced materials that promise enhanced performance, durability, and efficiency. Among these innovative materials, the Corundum Mullite Plate stands out due to its exceptional properties, making it a top choice in various applications. This guide aims to explore the multifaceted benefits and applications of Corundum Mullite Plates, demonstrating their vital role in modern manufacturing, construction, and specialized industrial processes.

The unique composition of Corundum Mullite Plates combines high alumina content with mullite, resulting in a material that boasts excellent thermal stability, resistance to wear and corrosion, and superior mechanical strength. These characteristics not only prolong the lifespan of components but also contribute to cost savings and operational efficiency in high-demand environments. As industries continue to seek sustainable and effective solutions, understanding the practical applications and benefits of Corundum Mullite Plates will be crucial for businesses aiming to stay competitive in the evolving market landscape.

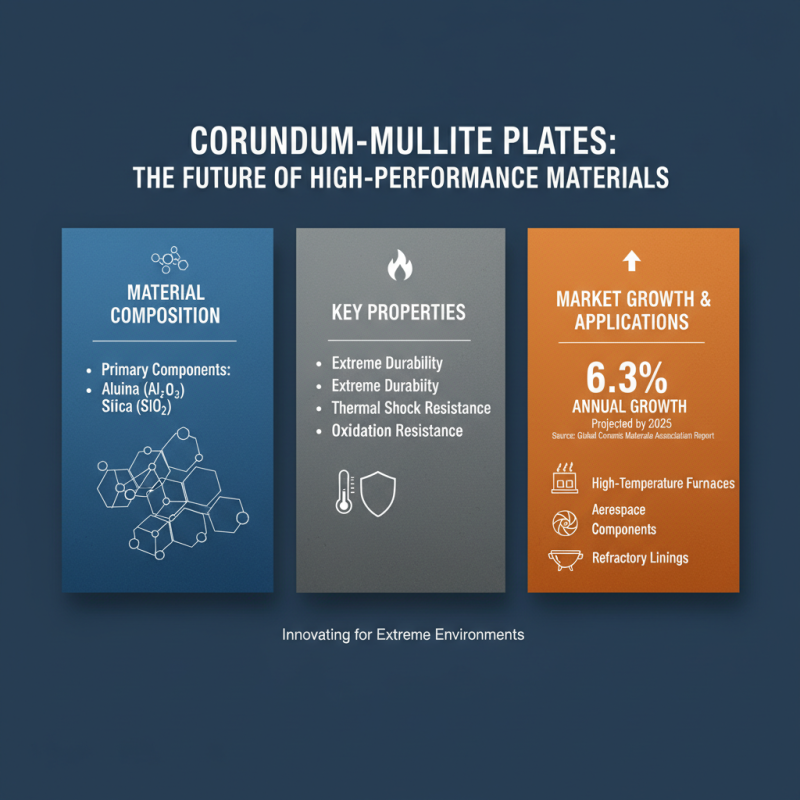

Corundum mullite plates represent a significant advancement in high-performance materials, combining the unique properties of corundum and mullite to create a highly durable and thermally stable product. Comprised primarily of alumina (Al2O3) and silica (SiO2), these plates exhibit exceptional resistance to thermal shock and oxidation. According to a recent industry report from the Global Ceramic Materials Association, the annual growth rate of the corundum mullite market is projected to reach 6.3% by 2025, driven by increasing demand in various high-temperature applications.

The properties of corundum mullite plates make them ideal for use in industries ranging from ceramics to aerospace. They can withstand temperatures exceeding 1600°C, making them suitable for furnaces, kilns, and other applications where conventional materials would fail. Additionally, their low thermal conductivity minimizes heat loss, thus enhancing energy efficiency. Furthermore, their mechanical strength and wear resistance allow for prolonged service life, reducing the need for frequent replacements and maintenance. As companies prioritize sustainability and cost-effectiveness, the adoption of corundum mullite plates is poised to expand across several sectors.

Corundum mullite plates have gained significant traction across various industries due to their remarkable characteristics, making them a popular choice for high-performance applications. In the manufacturing sector, these plates are increasingly utilized in kiln linings and refractory components, owing to their excellent thermal stability and low thermal expansion. This property not only enhances durability but also reduces energy consumption during production processes, making it a compelling option for industries focused on sustainability.

In the aerospace and automotive sectors, corundum mullite plates are favored for their lightweight yet robust nature. These plates contribute to the overall efficiency of parts and components subjected to extreme conditions. The high resistance to thermal shock further extends their application in engines and exhaust systems, where both strength and reliability are paramount.

**Tip:** When selecting corundum mullite plates for your projects, consider factors such as the specific operating temperatures and environmental conditions to ensure optimal performance.

Additionally, the electronics industry benefits from corundum mullite plates in the production of substrates for electronic circuits. Their electrical insulating properties, combined with the ability to withstand high temperatures, make them ideal for applications in modules and devices that require both reliability and efficiency.

**Tip:** Regularly assessing the performance of mullite plates in electronic applications can lead to potential innovations and efficiency improvements.

| Application Area | Industry | Key Benefits | Temperature Resistance (°C) |

|---|---|---|---|

| Energy Production | Power Generation | Enhances energy efficiency | 1600 |

| Chemical Processing | Petrochemicals | Corrosion resistance | 1450 |

| Metallurgical | Steel Industry | Durability and strength | 1800 |

| Manufacturing | Ceramics | Enhanced thermal stability | 1500 |

| Aerospace | Aviation | Lightweight and high strength | 1700 |

Corundum mullite plates are gaining increasing attention for their exceptional performance in high-temperature environments. Composed primarily of corundum and mullite, these plates exhibit superior thermal stability and mechanical strength, making them ideal for applications in industries such as metallurgy, ceramics, and aerospace. The combination of these two components allows for a low thermal expansion coefficient, which significantly reduces the risk of thermal shock during rapid temperature changes.

One of the primary benefits of using corundum mullite plates is their excellent resistance to extreme heat, withstanding temperatures exceeding 1600°C. This property not only enhances their durability but also extends their lifespan, reducing the need for frequent replacements. Additionally, their hardness and abrasion resistance ensure they maintain structural integrity even in demanding conditions, leading to increased operational efficiency. Moreover, these plates exhibit low porosity, which minimizes the absorption of harmful reagents and prevents degradation in corrosive environments, further solidifying their standing as a reliable choice in high-temperature settings.

When comparing corundum mullite plates to other materials, several key factors come into play, including thermal stability, mechanical strength, and resistance to thermal shock. Corundum mullite plates exhibit outstanding thermal endurance, making them suitable for high-temperature applications in industries such as ceramics and metal processing. Their unique composition combines the advantageous properties of both corundum and mullite, resulting in a product that not only withstands extreme conditions but also maintains dimensional stability under stress.

In contrast, materials such as alumina and silicon carbide, while also popular in high-performance environments, often fall short in terms of thermal shock resistance. Alumina, for instance, can be brittle and prone to cracking under rapid temperature changes, whereas silicon carbide, although incredibly hard, may not offer the same level of thermal stability as corundum mullite. As industries pursue more efficient and durable solutions into 2025 and beyond, the comparative advantages of corundum mullite plates highlight their role as an optimal choice for demanding applications, offering superior performance where reliability and resilience are crucial.

In recent years, the development of corundum mullite plates has gained significant attention due to their exceptional properties and wide-ranging applications in various industries. As we look towards 2025, key trends indicate a growing demand for these materials in sectors such as steel, ceramics, and high-temperature insulation. According to a market analysis by Smith & Associates, the demand for refractory materials, including corundum mullite plates, is projected to grow at a compound annual growth rate (CAGR) of 6.5% over the next five years, driven by increased industrial processes requiring enhanced thermal performance.

The future of corundum mullite plate technology is also shaped by advancements in manufacturing processes aimed at improving efficiency and performance. Recent developments have introduced ultra-high purity corundum mullite formulations, which demonstrate superior mechanical strength and thermal stability. A report from the International Refractories Association highlights that the enhanced durability of these new formulations could lead to a 30% reduction in replacement costs for industries relying heavily on refractory materials. Moreover, the shift towards sustainable practices and recycling in manufacturing processes is likely to influence the production of corundum mullite plates, aligning with global trends towards ecological responsibility. Such innovations underscore the significance of corundum mullite plates as not just functional materials but also pivotal players in advancing industrial sustainability.