Leave Your Message

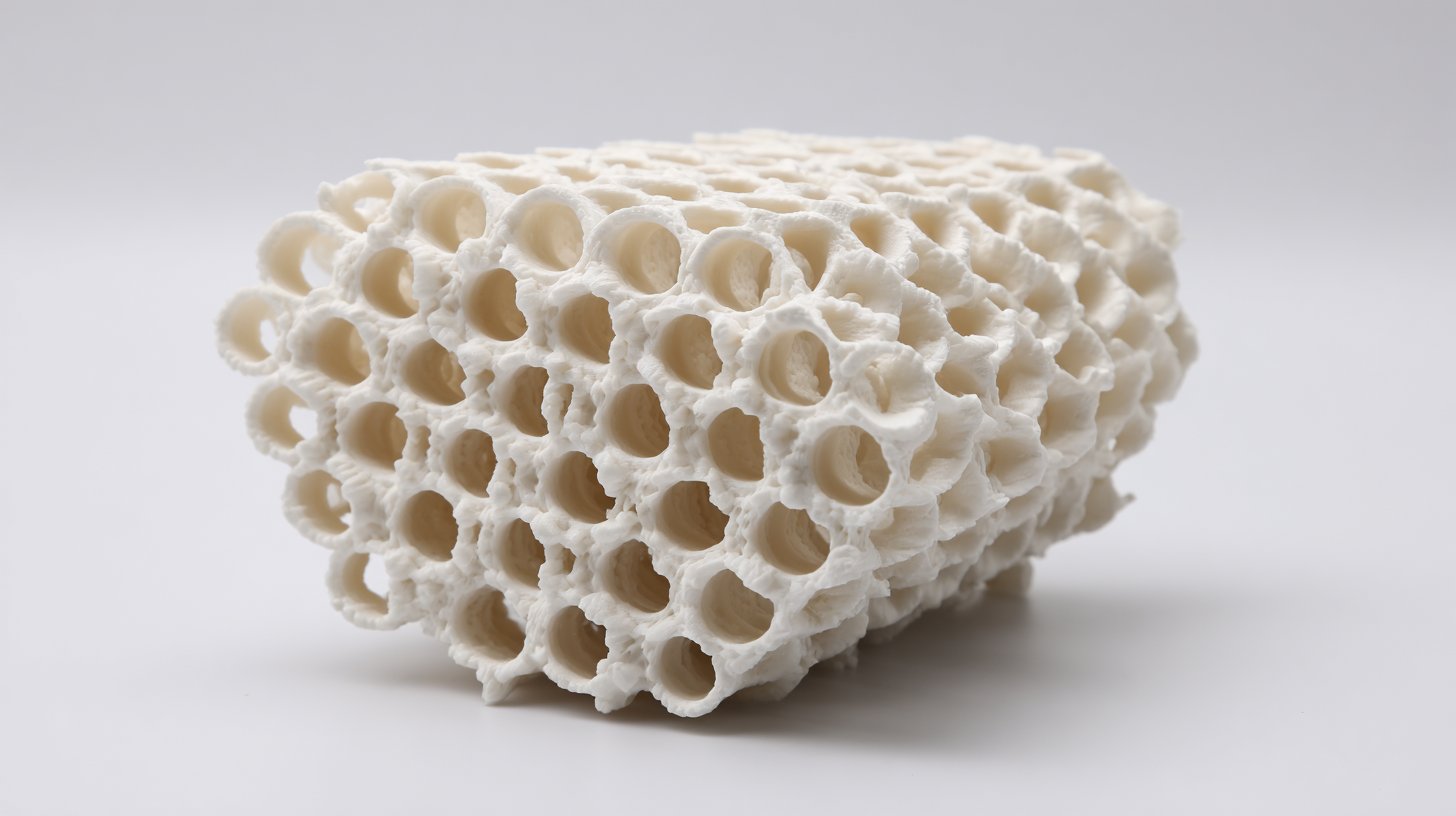

In the rapidly evolving landscape of industrial applications, the significance of Porous Alumina Ceramics is gaining unprecedented attention. Recent market research reports indicate that the global market for advanced ceramics is projected to reach $100 billion by 2025, with Porous Alumina Ceramics playing a pivotal role due to their superior thermal stability, chemical resistance, and customizable porosity. As industries seek advanced solutions for filtration, catalysis, and energy storage, the demand for high-performance porous materials is expected to surge. Emerging trends in this sector point towards innovations in manufacturing techniques and applications that enhance the functionality of these ceramics. Additionally, the integration of smart technologies and sustainable practices within their production and application is anticipated to further cement the position of Porous Alumina Ceramics as a vital component in future industrial advancements.

The future of porous alumina ceramics is set to revolutionize industrial applications by 2025, as innovative advancements are being made to enhance their properties and functionality. According to a recent market analysis by Research and Markets, the global porous ceramics market is projected to reach $7.6 billion by 2025, driven by an increasing demand for advanced materials in filtration, biomedical, and energy sectors. These advancements focus on improving the mechanical strength and thermal resistance of alumina ceramics, positioning them as a reliable choice for high-performance applications.

In parallel, ongoing research indicates that the integration of nanotechnology into the production of porous alumina ceramics is yielding remarkable outcomes. A study published in the Journal of Materials Science showcases that nanostructured alumina can achieve porosities exceeding 60% while maintaining robust structural integrity. Furthermore, the customized pore structure allows for enhanced adsorption properties, making porous alumina an excellent candidate for applications such as wastewater treatment and gas separation. As these innovations continue to unfold, industries will increasingly rely on porous alumina ceramics to meet growing performance demands.

In 2025, the demand for high-performance porous alumina ceramics is expected to surge, driven by the rapid advancements in technology and the increasing requirements for high thermal conductivity and stability in electronic components. As industries leverage innovations in porous alumina, the material's unique characteristics will position it as a vital player in applications ranging from smartphones to 5G base stations. The evolution of these ceramics will not only enhance product performance but also improve energy efficiency, responding to the growing emphasis on sustainable solutions in manufacturing.

Key characteristics such as superior heat resistance, mechanical strength, and lightweight nature will define the next generation of high-performance porous alumina ceramics. The ability to customize pore size and distribution will facilitate enhanced functionality in various industrial applications, making them indispensable in fields like aerospace, automotive, and electronics. Furthermore, the integration of advanced processing techniques will allow for improved quality control and scalability, ensuring that porous alumina remains at the forefront of material science in the years to come.

Sustainable manufacturing practices are becoming increasingly crucial in the production of advanced alumina ceramics. As industries strive to minimize their environmental impact, innovative approaches are being adopted to enhance the efficiency of alumina production processes. This includes the utilization of renewable energy sources and the implementation of energy-efficient technologies that reduce waste and lower carbon emissions. By integrating sustainable practices, manufacturers not only contribute to environmental preservation but also achieve cost savings and improve their market competitiveness.

Additionally, the use of eco-friendly materials and recycling methods in the processing of porous alumina ceramics is gaining traction. Many companies are exploring the potential of using post-consumer materials, which not only conserves raw materials but also minimizes landfill contributions. Advanced solutions that prioritize sustainability ensure that alumina ceramics can meet the demands of various industrial applications without compromising ecological integrity. This shift towards environmentally responsible manufacturing is setting a benchmark for the future of the ceramics industry, paving the way for innovations that align with global sustainability goals.

| Trend | Description | Industrial Applications | Sustainable Practices |

|---|---|---|---|

| Enhanced Porosity Control | Integration of advanced manufacturing techniques to achieve uniform porosity in alumina ceramics. | Filtration systems, biomedical applications. | Use of recycled materials in the production process. |

| Bioactive Alumina | Development of alumina ceramics that promote cell attachment and growth. | Dental and orthopedic implants. | Minimization of waste through efficient resource use. |

| Functional Coatings | Application of specialized coatings to enhance performance properties. | High-temperature applications, chemical processing equipment. | Adoption of low-energy firing techniques. |

| 3D Printing of Ceramics | Utilization of additive manufacturing for complex ceramic shapes. | Custom tooling, intricate designs for aerospace applications. | Reduction of material waste during production. |

| Smart Ceramics | Integration of sensors and actuators into ceramic materials for monitoring and control. | Infrastructure monitoring, aerospace component health monitoring. | Implementation of energy-efficient manufacturing methods. |

Porous alumina ceramics are becoming increasingly relevant in various emerging industrial sectors due to their unique properties, including high thermal stability, lightweight, and excellent mechanical strength. These materials are finding their way into advanced filtration systems, where their porosity allows for efficient separation of particles and contaminants. In sectors such as pharmaceuticals and water treatment, porous alumina is crucial for creating cleaner and safer environments, contributing to enhanced product quality and compliance with stringent regulations.

In the realm of energy storage, porous alumina ceramics play a pivotal role in the development of next-generation batteries and supercapacitors. Their high surface area facilitates greater ion mobility, leading to improved energy efficiency and performance. Additionally, industries focused on sustainable energy solutions, such as hydrogen production and fuel cells, are increasingly integrating porous alumina into their processes. As these sectors continue to expand, the demand for innovative porous alumina applications will also surge, paving the way for groundbreaking advancements in industrial solutions.

The development of porous alumina ceramics faces numerous challenges and opportunities, particularly as industrial applications continue to advance. One major challenge is balancing the properties of high porosity and mechanical strength, which are often at odds in traditional manufacturing processes. New approaches in additive manufacturing, particularly 3D printing technologies, are emerging as viable solutions. These techniques enable the precise control of geometries and material properties, facilitating the fabrication of superior ceramic components that meet industrial requirements.

Moreover, the growing demand for high-performance advanced ceramics in sectors such as medical implants and environmental technologies reflects substantial market potential. Innovations in photopolymerization processes for ceramic resins, combined with advancements in ceramic lattice structures, allow for more efficient designs that enhance application versatility. As industries increasingly adopt AI-driven solutions, the advanced ceramics market is projected to experience significant growth, presenting both challenges in material development and opportunities for pioneering applications in the next few years.

This chart illustrates the projected market demand for porous alumina ceramics from 2021 to 2025, indicating a significant growth trend as advanced solutions continue to emerge in industrial applications.