Leave Your Message

Choosing the right Cordierite Mullite Plate is crucial for various applications. These plates offer excellent thermal stability and resistance to thermal shock. This makes them ideal for use in kilns, ovens, and other high-temperature environments. Understanding your specific needs can help you make an informed decision.

When considering a Cordierite Mullite Plate, think about its size, shape, and thickness. These factors can greatly influence performance. Each application has unique requirements, and one size does not fit all. You may need to experiment to find the perfect match.

Additionally, not all suppliers guarantee consistent quality. Be cautious when selecting a provider. Researching customer reviews can provide insight but may not tell the whole story. It’s important to weigh your options before making a final choice. This might seem simple, but small details matter.

Cordierite mullite plates are known for their unique composition. They consist mainly of cordierite and mullite, two minerals that provide excellent thermal stability. The combination results in a material that can withstand high temperatures without significant deformation. These plates are also lightweight, making them ideal for various applications.

In terms of properties, cordierite mullite plates exhibit low thermal expansion and high resistance to thermal shock. This means they can handle rapid temperature changes. They are often used in kilns, for example, due to this thermal resilience. One must consider these properties when selecting the right plate for specific needs.

However, not all cordierite mullite plates perform the same. Variations in composition can affect their effectiveness. Additionally, the manufacturing process can introduce imperfections, which impact performance. It is crucial to reflect on these aspects when making a choice. Evaluate the specific requirements of your application for the best outcome.

When selecting a cordierite mullite plate, pay close attention to thermal shock resistance. This feature determines how well the material can handle sudden temperature changes without cracking. A high resistance rating usually indicates better durability. It helps in high-temperature applications where rapid heating and cooling occur. A suitable plate can withstand heat fluctuations more reliably.

Next, consider the strength ratings of the chosen plates. Strength ratings reflect how much pressure the material can endure. This is vital for industrial uses where stability is essential. Materials may look good but may fall short in load-bearing scenarios. Always verify the strength specifications and test results. If unsure, seek guidance or perform tests yourself to ensure they're reliable. Balancing these factors may take time, but it’s necessary for long-term performance.

| Dimension (mm) | Thermal Shock Resistance (°C) | Flexural Strength (MPa) | Density (g/cm³) | Coefficient of Thermal Expansion (x 10⁻⁶ /°C) |

|---|---|---|---|---|

| 300 x 300 | 600 | 40 | 2.4 | 6.2 |

| 400 x 400 | 650 | 42 | 2.5 | 5.8 |

| 500 x 500 | 580 | 45 | 2.6 | 6.0 |

| 600 x 600 | 620 | 43 | 2.7 | 6.1 |

| 800 x 800 | 600 | 41 | 2.8 | 5.9 |

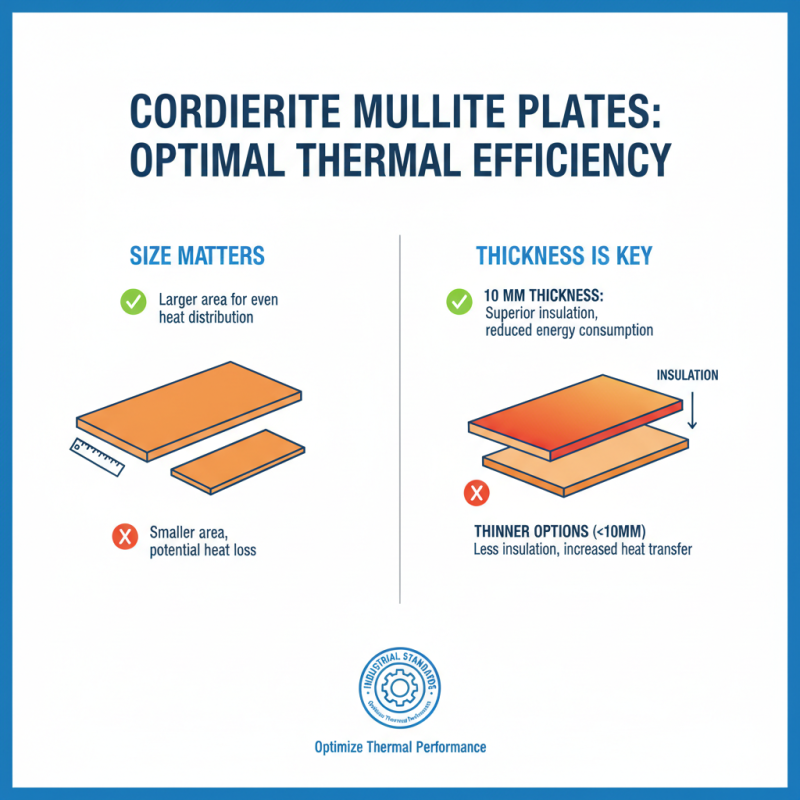

When selecting cordierite mullite plates, size and thickness are crucial factors. Industrial standards emphasize that the right dimensions optimize thermal efficiency. For example, plates with a thickness of 10 mm often provide better insulation than thinner options.

Understanding your specific application is vital. For instance, a report from the Materials Research Society notes that heavier machinery requires thicker plates. In these cases, a 15 mm thickness can withstand higher stress and temperature fluctuations. Consult industry data to assess the heat resistance needed for your environment.

Measuring the correct size isn’t always straightforward. Variability in production can lead to inconsistencies. A poorly sized plate can compromise performance. The importance of precision is highlighted in a recent study, which found that even a 1 mm difference can affect thermal conductivity by up to 10%. This underscores the need for careful evaluation.

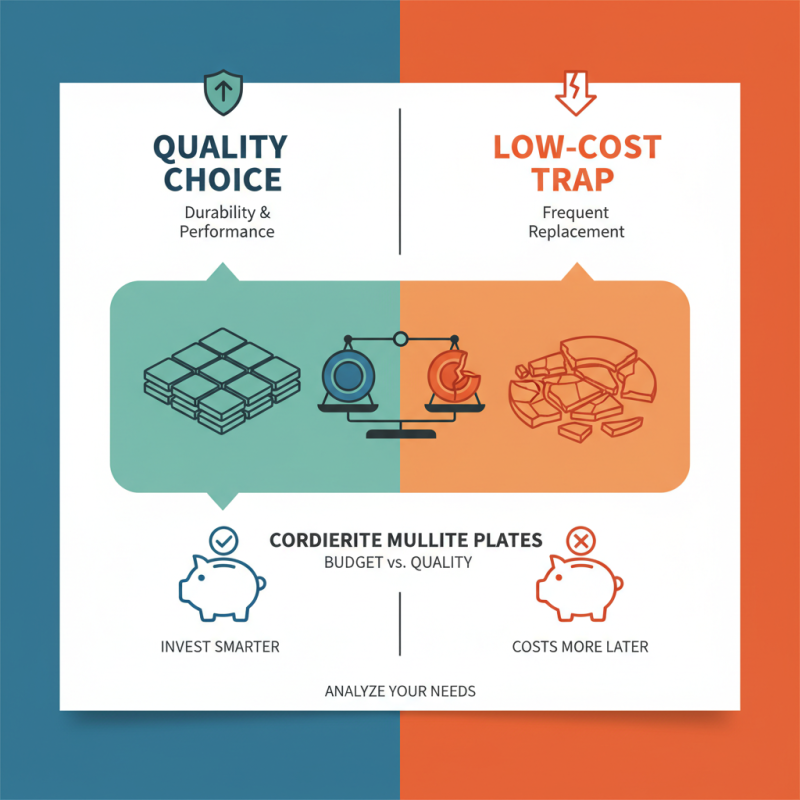

When selecting cordierite mullite plates, cost is a critical factor. High-quality materials often come at a premium. However, low-cost options can lead to poor performance. Analyzing your budget against quality requirements is essential. Sometimes the cheapest option costs more in the long run. It might crack or wear out quickly.

Finding a balance between price and quality can be tricky. Researching the market helps identify cost-effective choices that do not compromise durability. Look for suppliers who offer detailed specifications. Compare them to understand what you're really paying for. Remember, quality may save money over time. Reflect on the expected lifespan of the plates. Short-term savings can lead to greater expenses later.

It's vital to consider your specific needs. Ask yourself how the plates will be used. Will they endure extreme temperatures? Will they be exposed to harsh chemicals? Each use case demands different performance criteria. A mismatched choice can result in unforeseen costs. Prioritize essential features while remaining mindful of your budget. Keeping these factors in check drives better purchasing decisions.

Cordierite mullite plates are valued in various industries for their unique properties. These plates withstand high temperatures and thermal shocks. Applications in the ceramic industry often showcase their strength. For instance, they serve as kiln shelves, helping to support heavy loads during firing. Their ability to resist thermal expansion is beneficial. This quality prevents warping or cracking, which can be critical for precision tasks.

In the glass industry, cordierite mullite plates play a significant role. They are used in glass melting furnaces where high stability is crucial. Their resistance to chemical attacks further enhances their utility. However, selecting the right plate requires consideration of specific needs. Not every plate suits every application. An improperly chosen plate can lead to costly errors and production delays. Reflecting on these factors can save time and resources.