Leave Your Message

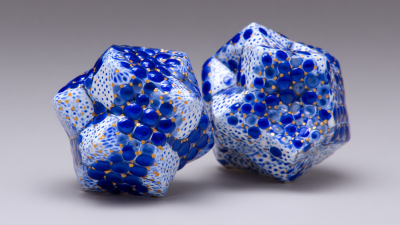

Choosing the right Zirconia Ceramic products can be challenging. With various options available, making an informed decision is crucial. Zirconia Ceramic is known for its durability and aesthetic appeal. These materials are used in many applications, from dental restorations to high-performance engineering components.

When selecting these products, consider factors like quality, price, and purpose. Each item may have unique features that appeal to specific needs. For instance, some Zirconia Ceramic products are designed for extreme conditions, while others focus on beauty and design. It's essential to understand your requirements before making a choice.

Reflect on your preferences and the intended use. Are you looking for strength or elegance? Keep in mind that not every product on the market meets the same standards. Exploring various brands and their offerings can be helpful. Always ask questions and seek reliable information. Making the right choice can lead to satisfaction and better results in your projects.

Zirconia ceramic is widely praised for its durability and aesthetic appeal. Composed primarily of zirconium dioxide, it exhibits remarkable strength, making it ideal for various applications. Studies show that zirconia can withstand extreme pressure and resist wear, leading to a longer lifespan in products. This has made it highly sought after in industries such as dentistry and manufacturing.

When choosing zirconia ceramic products, consider the quality of composition. Higher purity levels translate to better performance. Pay attention to the manufacturing processes used. Advanced techniques enhance the material's properties, resulting in superior outcomes.

Tip: Always ask about the material's density. Higher density zirconia typically offers greater strength and longevity.

Zirconia ceramic also provides aesthetic benefits. Its ability to mimic natural materials makes it popular in dental applications. Nevertheless, achieving the perfect color match can be challenging.

Tip: Test samples before final selections. This helps ensure that the desired appearance meets your expectations. Remember, slight imperfections are common in the manufacturing process, so it's vital to assess every product carefully.

This bar chart illustrates key properties of zirconia ceramics, including strength, density, thermal conductivity, flexural strength, and fracture toughness. The data showcases the exceptional mechanical and thermal properties that make zirconia ceramics suitable for various applications in industries such as dentistry, aerospace, and electronics.

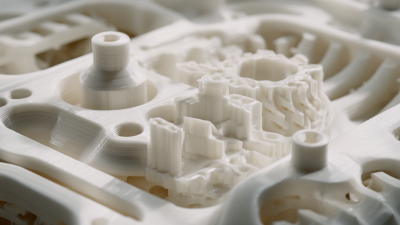

When choosing zirconia ceramic products, several key factors influence their quality and performance. One significant aspect is the manufacturing process. The method used can vary widely. Poor production techniques may lead to defects, compromising the product's durability and aesthetics. Checking for proper sintering processes is crucial. High-quality sintering leads to better density and strength.

Another important factor is material composition. The purity of zirconia affects its resilience. Impurities can weaken the structure. Analyzing the grain size also matters. Smaller grains generally improve strength. This is vital for ceramics used in dental and industrial applications. Additionally, consider the finished surface quality. A smooth finish not only enhances appearance but also functionality. If flaws are present, rethink the choice.

Lastly, temperature stability is essential. Some zirconia ceramics perform poorly under heat, leading to failures in high-stress environments. Testing the thermal properties helps ascertain suitability. These elements require careful consideration. Rushing through the selection process can lead to significant issues later on. A thoughtful approach pays off in the long run.

When comparing zirconia ceramic to other ceramic materials, it's clear that zirconia has unique properties. Zirconia boasts high strength and durability, making it ideal for various applications. This material resists scratches and heat, outperforming traditional ceramics in many tests. However, its production can be more complex and expensive, posing challenges for some consumers.

Other ceramics, like porcelain and stoneware, are widely available and less costly. They offer decent strength but may chip or crack under stress. These materials are often easier to mold and shape into intricate designs. However, their longevity and performance in demanding settings can fall short compared to zirconia. It’s essential to weigh these aspects carefully before making a decision.

One must also consider the aesthetic appeal. Zirconia can be less visually adaptable compared to traditional ceramics. Some designs might not translate well into zirconia due to its manufacturing constraints. Consumers often find themselves reflecting on their priorities: Is durability more crucial than style? That dilemma can shift preferences in the ceramic market.

When evaluating zirconia ceramic products, industry standards and certifications play a crucial role. These benchmarks provide insight into quality and performance. Look for products that meet recognized standards. Certifications indicate that the item has undergone rigorous testing. It reflects reliability and safety in use.

One noteworthy certification is ISO 13485, which applies to medical devices. It ensures that products used in healthcare meet strict quality management criteria. Similarly, there are certifications for dental applications. These assure that the ceramics can withstand the demands of a clinical environment. However, not all manufacturers maintain these standards consistently. Some may overlook necessary tests to cut costs.

Understanding these certifications is essential, yet not always straightforward. Different regions may have varying standards, leading to confusion. Buyers should conduct thorough research before making a choice. Seek detailed specifications, and don’t hesitate to ask questions. Transparency from manufacturers is a red flag if absent. Balancing quality and affordability requires vigilance, not just trust.

When considering Zirconia ceramic products, a cost-benefit analysis is essential. Data reports suggest that Zirconia ceramics can reduce maintenance costs by up to 30% compared to traditional materials. Their durability and resistance to wear make them a worthy investment.

Tip: Evaluate the lifecycle of the product. Zirconia ceramic typically has a longer lifespan, meaning fewer replacements over time. This translates to lower long-term costs. In environments prone to high stress, Zirconia's strength is unmatched.

However, prices can be higher upfront. For some buyers, this may lead to hesitation. Studies indicate that higher initial costs can deter 40% of potential customers. Yet, once maintenance and eventual replacement costs are factored in, Zirconia often becomes more economical.

Tip: Consider your specific application needs. The right Zirconia ceramic solutions can significantly enhance performance. A tailored choice can ensure optimal results and a more effective investment. However, you should always reflect on whether the chosen product meets your anticipated usage scenarios.