Leave Your Message

In today's competitive landscape, selecting the appropriate materials is crucial for maintaining quality and performance in manufacturing. Zirconia Ceramic has emerged as a leading choice across various industries due to its exceptional properties, including high strength, wear resistance, and biocompatibility. According to a recent market analysis by Research and Markets, the zirconia ceramics market is projected to reach USD 2.2 billion by 2025, growing at a CAGR of 4.7% from 2020. This surge is driven by increasing applications in dental, biomedical, and electronics sectors, where the demand for high-performance materials is on the rise. Understanding the different types of zirconia ceramic, their specific properties, and their suitability for various applications is vital for businesses aiming to enhance product quality and operational efficiency. In this ultimate guide, we will delve into essential factors to consider when choosing the right zirconia ceramic for your business needs, ensuring informed decisions that align with industry standards and expectations.

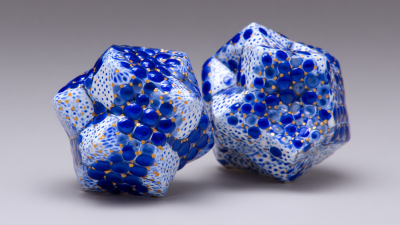

Zirconia ceramics stand out in various industries due to their exceptional properties and versatile benefits. Composed primarily of zirconium dioxide, these materials are known for their incredible strength and durability, making them suitable for high-stress applications. Their high fracture toughness, along with resistance to wear and corrosion, positions zirconia ceramics as a reliable choice for demanding environments, such as dental applications and industrial machinery components.

In addition to their mechanical advantages, zirconia ceramics exhibit excellent thermal properties. They have low thermal conductivity and high thermal stability, which allows them to maintain performance under extreme temperatures. This makes them ideal for applications in aerospace and automotive sectors, where thermal resistance is crucial. Furthermore, their biocompatibility enhances their appeal in the medical field, particularly for dental implants and prosthetics, ensuring they can be safely integrated into the human body without adverse effects. Understanding these key properties and benefits is essential for businesses looking to select the right zirconia ceramic tailored to their specific needs.

When selecting zirconia ceramic for your business, understanding your specific needs is paramount. Begin by evaluating the operational environment where the material will be utilized. Consider factors such as temperature, pressure, and exposure to chemicals, as these will directly influence the longevity and performance of the zirconia. For instance, if your application involves high temperatures, it's crucial to choose a zirconia that can withstand thermal stress without compromising structural integrity.

Next, assess the mechanical properties required for your application. Different industries may demand varying strengths, toughness, and wear resistance from their materials. For instance, in the dental industry, zirconia ceramics must exhibit high aesthetic appeal along with durability, while in industrial applications, exceptional wear resistance might be the key criterion. By clearly identifying these requirements, you ensure that the zirconia ceramic chosen not only meets current demands but also aligns with future business goals, ultimately leading to enhanced performance and customer satisfaction.

When selecting zirconia ceramics for your business, understanding the different types available is essential to meet your specific needs. Zirconia ceramics come in various forms, including fully stabilized, partially stabilized, and transformation-toughened options. Fully stabilized zirconia is known for its high mechanical strength and excellent wear resistance, making it an ideal choice for high-stress applications such as dental prosthetics and industrial tools. On the other hand, partially stabilized zirconia offers enhanced thermal stability and is often used in applications requiring resistance to thermal shock, such as in thermal barrier coatings.

Another important consideration is the transparency of the zirconia ceramic. For aesthetic applications, like dental restorations, translucent zirconia is preferred due to its ability to mimic the natural appearance of teeth. In contrast, opaque zirconia is better suited for structural applications where appearance is not a primary concern but strength and durability are vital. Evaluating your project's requirements, including mechanical properties, aesthetic needs, and application environments, is crucial in choosing the right type of zirconia ceramic for optimal performance and longevity.

When it comes to incorporating zirconia ceramics into your business, cost analysis plays a crucial role in budget planning. Zirconia ceramics are an investment that can yield benefits such as durability and aesthetic appeal, but understanding the associated costs is essential for making informed decisions. Begin by assessing the specific requirements of your project, as different applications will have varying material needs and pricing structures. Explore the market for options ranging from high-end professional 3D printers to more affordable desktop solutions, which can significantly impact your budget.

Tips for Cost-Effective Budgeting:

1. Research various suppliers and compare prices not only for the zirconia materials but also for the machinery required for producing or printing them.

This will help you gain a comprehensive view of your total expenditure.

2. Consider the long-term benefits of investing in higher-quality materials and machinery versus the potential drawbacks of cheaper alternatives.

Quality often correlates with longevity and performance, which can save costs over time.

3. Don’t overlook the potential for bulk purchasing discounts.

If your business plans to use zirconia ceramics extensively,

negotiating with suppliers for bulk pricing can lead to significant savings.

Zirconia ceramics have become increasingly pivotal in various industries due to their exceptional mechanical properties and thermal stability. According to a recent report from ResearchAndMarkets, the global market for zirconia ceramics is projected to reach approximately $2 billion by 2026, driven by the burgeoning demand in sectors such as biomedical, automotive, and electronics. In the biomedical field, zirconia is widely utilized in dental implants due to its biocompatibility and aesthetic appearance, providing an optimal solution for patients and practitioners alike.

In the automotive industry, zirconia ceramics are used in fuel cells and oxygen sensors, enhancing performance and reducing emissions. A study published in the Journal of Materials Science indicates that the integration of zirconia can improve the durability and efficiency of these components significantly. Furthermore, in the electronics sector, zirconia's dielectric properties make it ideal for capacitors and insulators, enabling manufacturers to produce smaller, more efficient devices. As industries continue to innovate, zirconia ceramics are poised to play a critical role in meeting the diverse needs and challenges of modern technology.