Leave Your Message

In the competitive landscape of ceramic manufacturing, sourcing high-quality materials is crucial for maintaining product integrity and operational efficiency. A pivotal component that has gained traction in the industry is the Corundum Mullite Sagger, which offers exceptional thermal stability and mechanical strength.

According to a recent market research report by Grand View Research, the global ceramic industry is projected to reach USD 466.9 billion by 2026, with a growing emphasis on advanced materials like corundum mullite. This material not only withstands extreme temperatures but also plays a vital role in enhancing the overall quality of fired ceramic products.

As businesses strive to meet increasing demands while optimizing production processes, understanding the nuances of procuring the right Corundum Mullite Sagger becomes essential. This ultimate guide aims to provide valuable insights into effectively sourcing this critical component for your business needs.

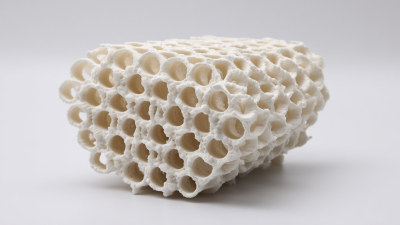

Corundum mullite saggers are essential in high-temperature applications due to their exceptional thermal shock resistance and mechanical strength. Composed of aluminum oxide and silica, these materials exhibit superior durability and are commonly used in the ceramics industry, particularly for firing high-value ceramics. Their ability to withstand extreme temperatures makes them a preferred choice for applications like kiln furniture, ensuring that products retain their shape and integrity during the firing process.

In the context of sustainable practices, the recent focus on hydrometallurgical recycling highlights the importance of waste saggar. With environmental regulations tightening and the need for resource conservation becoming prominent, industries are exploring efficient recycling methods. The leaching kinetics and mechanisms influenced by various additives can significantly affect the recovery of valuable elements from waste saggar. This shift not only aids in resource conservation but also aligns with the push towards more eco-friendly operations.

Tips: When selecting corundum mullite saggers, consider their thermal properties and compatibility with your specific firing processes. Additionally, investing in recycling technology can enhance your resource efficiency and reduce environmental impact. Embrace innovative approaches to reuse materials, which can help drive sustainability in your business.

The demand for corundum mullite saggers has been witnessing a steady rise, driven by the booming ceramics and refractory industries. As manufacturers seek to enhance product quality and efficiency, the need for high-performance saggers that can withstand extreme temperatures and provide excellent thermal stability has never been greater. Recent market analysis indicates a shift towards sourcing materials that are not only durable but also cost-effective, prompting businesses to explore innovative supply chains.

In addition to the current trends, projections for the corundum mullite sagger market suggest sustained growth in the coming years. Factors such as the expansion of the construction sector and the increasing popularity of advanced ceramics are likely to influence demand significantly. Furthermore, technological advancements in sagger production are expected to improve product quality, thereby attracting a wider customer base. As companies navigate this evolving landscape, understanding these trends will be crucial for sourcing the right products to meet their business needs effectively.

When sourcing high-quality corundum mullite saggers for your business needs, evaluating their quality is crucial to ensure optimal performance and durability in your applications. One essential tip is to check the raw materials used in the production of the saggers. High-purity alumina and mullite should be prioritized, as they significantly enhance thermal shock resistance and structural integrity. Look for manufacturers who provide detailed specifications and certification for the materials they use.

Another important consideration is the manufacturing process. Pay attention to the firing temperature and duration, as these factors directly influence the strength and stability of the saggers. A high-quality sagger should exhibit uniform density and minimal porosity. Request samples whenever possible, so you can conduct tests to assess their performance under your specific working conditions.

Lastly, customer reviews and industry reputation can be invaluable resources. Choose suppliers who have a proven track record of supplying reliable products and excellent customer service. Engage with other businesses in your field to gain insights and recommendations on the best sources for corundum mullite saggers. This approach will help ensure you make informed decisions that align with your operational requirements.

| Specification | Value | Comments |

|---|---|---|

| Material Composition | Corundum & Mullite | High thermal stability |

| Temperature Resistance | Up to 1650°C | Suitable for high-temperature applications |

| Size (mm) | 300 x 300 x 500 | Common size for industrial use |

| Weight (kg) | 25 | Lightweight yet durable |

| Thermal Conductivity | 0.2 W/m·K | Excellent insulation properties |

| Application | Ceramic firing | Suitable for various firing processes |

When considering the investment in corundum mullite saggers, one must conduct a thorough cost analysis to recognize the long-term savings they can bring. While the initial price may seem higher compared to lower-quality alternatives, the durability and performance of high-quality saggers significantly reduce replacement and maintenance costs. Over time, these savings can surpass the upfront investment, making them a wise choice for businesses aiming for efficiency and longevity in their production processes.

Furthermore, high-quality corundum mullite saggers enhance operational productivity by maintaining consistent thermal stability and excellent load-bearing capacities. This reliability minimizes production downtime caused by sagger failures, which can be costly in terms of both time and resources.

By investing in these superior products, businesses not only benefit from immediate operational efficiencies but also position themselves for success in the competitive market, where high standards and reliability are paramount for customer satisfaction and retention.

When selecting a manufacturer for high-quality corundum mullite saggers, it's essential to understand the nuances of supplier selection criteria. The guidance provided in recent insights emphasizes the difference between selection and award criteria, underscoring the importance of mandatory versus discretionary criteria. This clarity allows businesses to make informed decisions that align with industry standards, ensuring the chosen supplier meets both operational needs and regulatory requirements.

Supply chain transparency has emerged as a vital component in supplier selection, offering manufacturers insights into the complexity of their supply chains. By understanding the journey from raw materials to finished products, businesses can better assess potential suppliers. Implementing a rigorous evaluation system based on sustainability pillars—economic, environmental, and social performance—enhances supplier identification and fosters partnerships that promote long-term success. Furthermore, leveraging digital tools for supply chain risk assessment can streamline the selection process, helping companies navigate today’s demanding marketplace with greater confidence.