Leave Your Message

In today's fast-paced industrial landscape, maximizing efficiency is more critical than ever, and one of the most promising materials for achieving this is Porous Alumina Ceramics. According to a recent report by MarketsandMarkets, the global ceramic materials market is poised to reach $320 billion by 2025, with the demand for advanced ceramics, including porous varieties, growing significantly due to their superior performance characteristics.

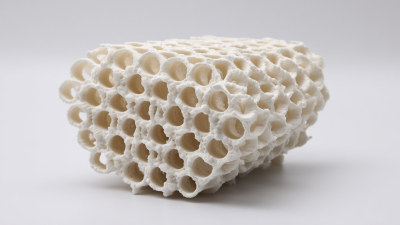

Porous Alumina Ceramics are known for their excellent thermal stability, high mechanical strength, and chemical resistance, making them ideal for applications in filtration, catalysis, and thermal insulation. By leveraging these unique properties, industries can enhance operational efficiency, reduce energy consumption, and lower costs.

This blog will explore strategies for effectively utilizing Porous Alumina Ceramics in various industrial applications, providing valuable insights and tips to help businesses stay ahead in a competitive market.

Porous Alumina Ceramics are known for their excellent thermal stability, high mechanical strength, and chemical resistance, making them ideal for applications in filtration, catalysis, and thermal insulation. By leveraging these unique properties, industries can enhance operational efficiency, reduce energy consumption, and lower costs.

This blog will explore strategies for effectively utilizing Porous Alumina Ceramics in various industrial applications, providing valuable insights and tips to help businesses stay ahead in a competitive market.

Achieving optimal porosity in porous alumina ceramics is a critical challenge that impacts their performance in various industrial applications. The ideal porosity levels can enhance properties like mechanical strength, thermal stability, and filtration efficiency. However, studies reveal that deviations from optimal porosity can drastically affect these attributes. According to a report by the Journal of Advanced Ceramic Materials, a porosity range of 30-50% typically yields the best mechanical properties for alumina ceramics, while exceeding these levels can lead to brittleness and reduce resilience.

Moreover, the methods employed to create porosity significantly influence the final product quality. Techniques such as foam replication, sintering with porogens, and chemical leaching each present unique challenges. A comprehensive analysis published by the International Journal of Applied Ceramic Technology indicates that controlling the pore size distribution is essential; it should ideally fall between 20 to 100 micrometers for effective filtration processes. This control not only addresses the strength-to-weight ratio but also ensures consistent performance across a range of operational conditions. By focusing on these critical parameters, industries can better harness the potential of porous alumina ceramics in their applications.

The mechanical integrity of porous alumina ceramics is crucial for their performance in various industrial applications. The unique porous structure not only facilitates lightweight designs but also enhances thermal and chemical resistance. However, this porosity must be carefully controlled to prevent compromising mechanical strength. Manufacturers must consider factors like pore size, distribution, and interconnectivity, which can significantly influence the material's ability to withstand stress and reduce the risk of fractures.

Tip: When designing components with porous alumina, it's essential to conduct thorough simulations to predict how different porosity levels affect performance under load. Employing advanced modeling techniques can help identify the optimal porosity that balances weight reduction and structural integrity.

Moreover, the processing methods used to create these ceramics play a significant role in defining their mechanical properties. Techniques such as sintering and templating can help achieve a fine-tuned porosity that retains strength while meeting application-specific demands. By refining these methods, manufacturers can enhance the durability and reliability of porous alumina ceramics in challenging environments.

Tip: Regular assessments and tests of mechanical properties during the production phase can lead to improvements in process control, ensuring consistent quality and performance of the final product.

Porous alumina ceramics are widely utilized in various industrial applications due to their exceptional mechanical properties and lightweight characteristics. However, common defects in these materials, particularly porosity, significantly influence their performance. Studies have shown that defects such as large-sized irregular-shaped pores can lead to reduced tensile strength and compromised structural integrity. For example, the experimental assessment of tensile loading on alumina ceramics demonstrates that variations in porosity directly correlate with the materials' strength and fragmentation behavior, highlighting the need for careful consideration during the manufacturing process.

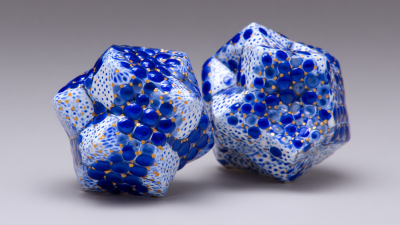

Recent advancements have introduced innovative approaches to mitigating such defects. The introduction of core-shell microspheres as pore-forming agents has led to the formation of closed pores, which can enhance the mechanical properties of porous alumina ceramics. Additionally, refinements in the sintering process, including the use of refining flux like Na3AlF6, have shown promise in transforming shrinkage pores into more desirable spherical hydrogen pores. These modifications not only enhance the structural dynamics but also improve the materials' performance—ultimately paving the way for more efficient applications in industries ranging from automotive manufacturing to catalyst support systems.

This chart illustrates various common defects found in porous alumina ceramics and their associated impact on performance metrics.

Porous alumina ceramics have garnered increasing attention in industrial applications due to their exceptional properties such as lightweight, high porosity, and excellent thermal stability. To enhance the durability of porous alumina ceramics, implementing advanced processing techniques is essential. According to a recent report by the The American Ceramic Society, the durability of alumina ceramics can be significantly improved through optimized sintering processes, which reduce porosity while maintaining permeability. This attention to microstructure enables the ceramics to withstand harsher operating conditions, extending their lifecycle in demanding industrial settings.

Another key strategy for enhancing durability lies in the incorporation of additives during the manufacturing process. Research published in the Journal of Materials Science indicates that adding materials like silica or zirconia can refine the grain structure of alumina ceramics, leading to increased toughness and resistance to crack propagation. These modifications not only improve performance under mechanical stress but also enhance chemical resistance, making porous alumina ceramics suitable for use in environments exposed to corrosive substances, thus boosting their overall reliability in various industrial applications.

Porous alumina ceramics are increasingly recognized for their potential in industrial applications, particularly when balancing cost and performance trade-offs. A key consideration in these applications revolves around optimizing material properties without compromising on efficiency. The challenge lies in achieving the right balance between attributes such as strength and toughness, which can significantly impact performance. For instance, in processes like bioethanol production via pervaporation, the efficiency of separation heavily depends on the interplay between membrane permeability and selectivity, making it critical to choose materials that support these demands.

**Tips:**

1. When selecting porous alumina for your project, consider the specific application requirements to identify the most suitable properties for your needs.

2. Experiment with different fabrication methods to enhance material performance while keeping costs manageable. Advanced techniques can provide better structural integrity without inflating budgetary constraints.

3. Stay informed about recent advancements in material science, such as tight ultrafiltration membranes, to leverage cutting-edge developments that can further amplify efficiency in your applications.