Leave Your Message

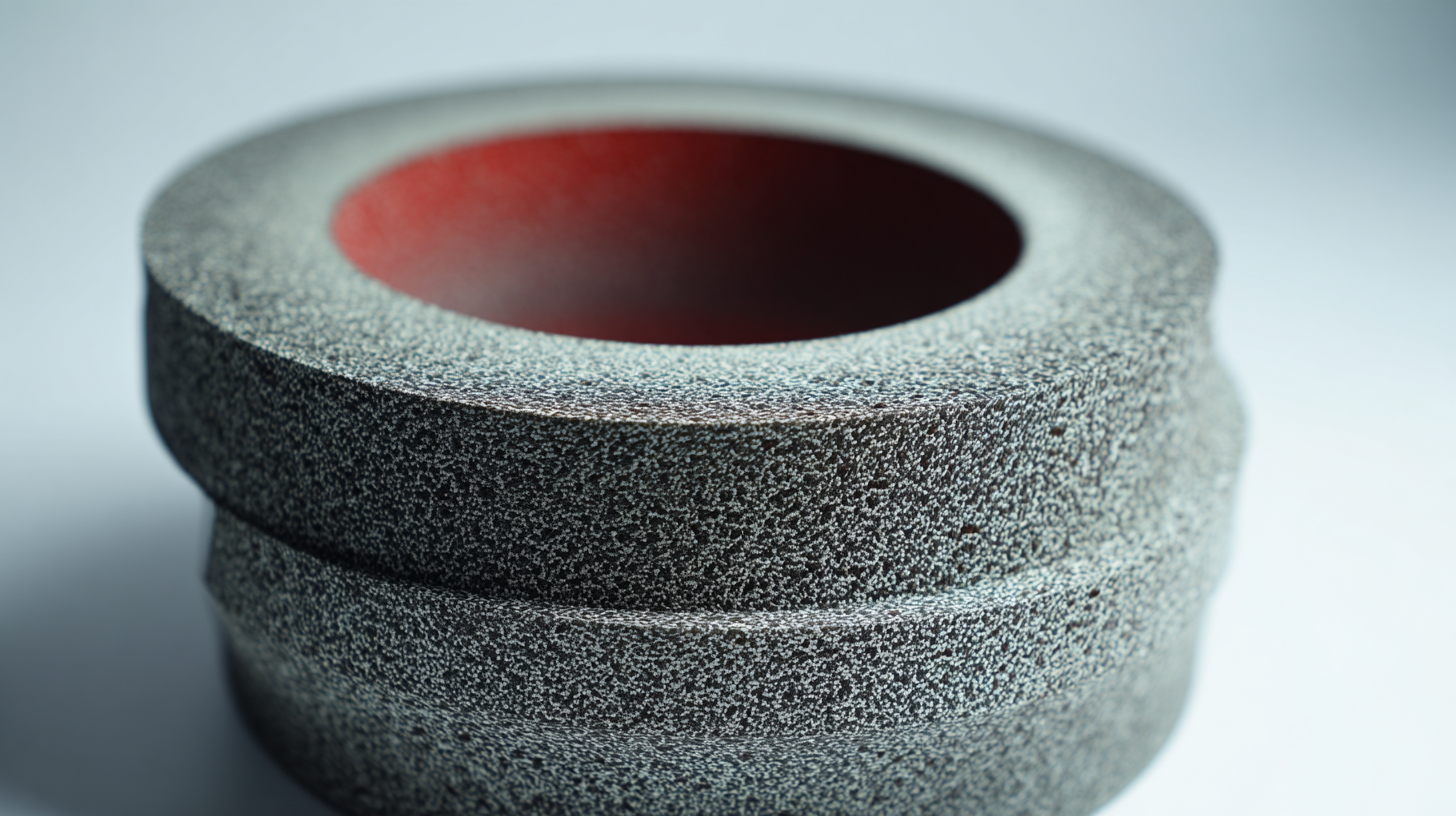

In the realm of advanced materials, Technical Ceramic has emerged as a crucial component for high-temperature applications across various industries, including aerospace, automotive, and energy sectors. According to a report by MarketsandMarkets, the global technical ceramics market is projected to reach USD 101.3 billion by 2025, driven by their superior thermal stability and mechanical properties. These ceramics exhibit exceptional wear resistance and can sustain their integrity under extreme temperatures, making them indispensable in applications such as turbine blades and thermal barriers. However, to harness their full potential, it is vital to optimize their performance through careful material selection, processing techniques, and design considerations.

This blog will delve into effective strategies and practical tips for enhancing the performance of Technical Ceramic in high-temperature scenarios, ensuring reliability and efficiency for manufacturers and end-users alike.

The properties of technical ceramics are crucial for their performance in high-temperature applications. These materials, primarily composed of alumina, silica, and other ceramic compounds, exhibit remarkable thermal stability and resistance to extreme environments. A recent report highlights that the ceramic fiber market is projected to grow significantly, driven by the increasing adoption of lightweight and high-temperature insulating materials across various industries. This growth reflects the essential role that technical ceramics play in enhancing thermal efficiency and safety in high-performance applications.

Advanced ceramics, increasingly recognized as a vital segment of new materials, have demonstrated their potential in sectors like aerospace, where they are used to address lubrication failures in metal bearings under extreme conditions. Innovations in dielectric ceramics have also led to improvements in energy storage performance, vital for high-power applications such as electric vehicles and laser devices. As these technologies advance, adherence to national standards, such as the recently established guidelines for silicon nitride ceramic substrates, will be crucial to ensure reliability and safety in high-temperature applications. This emphasizes the ongoing investment in optimizing the performance of technical ceramics to meet the escalating demands of modern engineering challenges.

| Property | Description | Importance in High Temp |

|---|---|---|

| Thermal Conductivity | Ability to conduct heat | Critical for heat dissipation |

| Thermal Shock Resistance | Ability to withstand sudden temperature changes | Prevents cracking from thermal stress |

| Strength and Toughness | Resistance to deformation and fracture | Ensures reliability under mechanical stress |

| Chemical Stability | Resistance to oxidation and degradation | Prolongs lifespan in harsh environments |

| Electrical Insulation | Ability to resist electric current | Essential in electronic applications at high temperatures |

Selecting the right technical ceramic material for high-temperature applications is pivotal in optimizing performance. Various critical factors come into play, including thermal stability, mechanical strength, and chemical resistance. According to a recent market report, the global ceramics substrate market is projected to reach $13.5 billion by 2032, with a compound annual growth rate (CAGR) of 6.42% from 2023 to 2032. This growth underscores the increasing demand for high-performance ceramics that can withstand extreme conditions.

In high-temperature environments, the thermal properties of ceramics are essential. Materials must be able to maintain their structural integrity while resisting thermal shock. The semiconductor materials industry highlights this need, as these materials need to achieve a balance between conductivity and insulation. With semiconductor materials’ unique properties falling between conductors and insulators, selecting the appropriate ceramic can significantly impact efficiency in electronic applications. As the global market for technical ceramics expands—projected to reach $5.1 billion by 2032 at a CAGR of 6.1%—the focus on optimizing material selection will likely remain a key driver in achieving superior performance in high-temperature scenarios.

Innovative manufacturing techniques play a crucial role in optimizing the performance of technical ceramics for high-temperature applications. Recent advancements have showcased the potential of additive manufacturing, notably ceramic stereolithography, which simplifies the manufacturing process of cellular ceramics. This method addresses traditional additive manufacturing limitations, offering a more streamlined approach that enhances both efficiency and material properties.

By leveraging 3D printing techniques, researchers have achieved notable improvements in the design and production of catalytic supports, demonstrating how these innovative processes can lead to enhanced performance in thermal management applications.

In addition, the integration of high-entropy alloy (HEA) doping within melt-grown eutectic ceramic composites marks another significant development. This innovative approach has proven effective in improving the mechanical properties and damage tolerance of ceramics, which are pivotal for applications in extreme environments. As detailed in recent reviews, the enhancement of ceramic materials through advanced manufacturing techniques is essential for meeting the demanding requirements of industries focusing on high-performance thermal and structural applications. These innovations not only promise improved functionality but also contribute to the development of sustainable manufacturing practices, ensuring that ceramics can effectively meet future energy and environmental challenges.

High temperature ceramics are essential in various industrial applications, from aerospace to energy production, where extreme thermal environments are the norm. To evaluate their performance effectively, a range of testing methods must be employed. One key technique is the use of thermal cycling tests, which assess a material's ability to withstand rapid temperature fluctuations while maintaining structural integrity. These tests simulate real-world conditions, providing valuable insights into the durability and reliability of the ceramic materials under stress.

Another important evaluation method is mechanical testing at elevated temperatures. This involves subjecting the ceramic to tensile, compressive, and flexural tests at high temperatures to measure its strength and elasticity. Understanding how these materials behave under load in a high-temperature context is crucial for ensuring their suitability in demanding applications. Additionally, advanced methods like thermal shock testing and oxidation resistance evaluations further enhance the understanding of a ceramic’s performance in extreme conditions, helping engineers optimize material selection and enhance overall operational efficiency.

In high temperature applications, the long-term performance of technical ceramics can be significantly enhanced through strategic maintenance practices. Regular inspections are essential to identify any potential wear or degradation early, especially in environments where thermal cycling and mechanical stress are prevalent. According to a recent report by the Advanced Materials Research Institute, ceramics in high-stress applications can experience up to 30% performance degradation over time if not properly maintained.

In high temperature applications, the long-term performance of technical ceramics can be significantly enhanced through strategic maintenance practices. Regular inspections are essential to identify any potential wear or degradation early, especially in environments where thermal cycling and mechanical stress are prevalent. According to a recent report by the Advanced Materials Research Institute, ceramics in high-stress applications can experience up to 30% performance degradation over time if not properly maintained.

Tip: Implement a scheduled maintenance routine that includes visual inspections and measurement of material properties to ensure early detection of issues.

Moreover, the application of protective coatings can greatly improve the lifespan of technical ceramics. Research shows that coatings not only provide a barrier against harsh environments but can also mitigate the effects of thermal shock. A study conducted by the Ceramic Engineering Society indicates that applying a suitable coating can extend the operational life of technical ceramics by up to 50%.

Tip: Choose coatings specifically designed for high-temperature applications, as they must withstand thermal cycling without compromising adhesion or integrity.

By adopting these maintenance strategies, industries can ensure optimal performance and durability of technical ceramics in high temperature applications, ultimately leading to cost savings and improved efficiency.