Leave Your Message

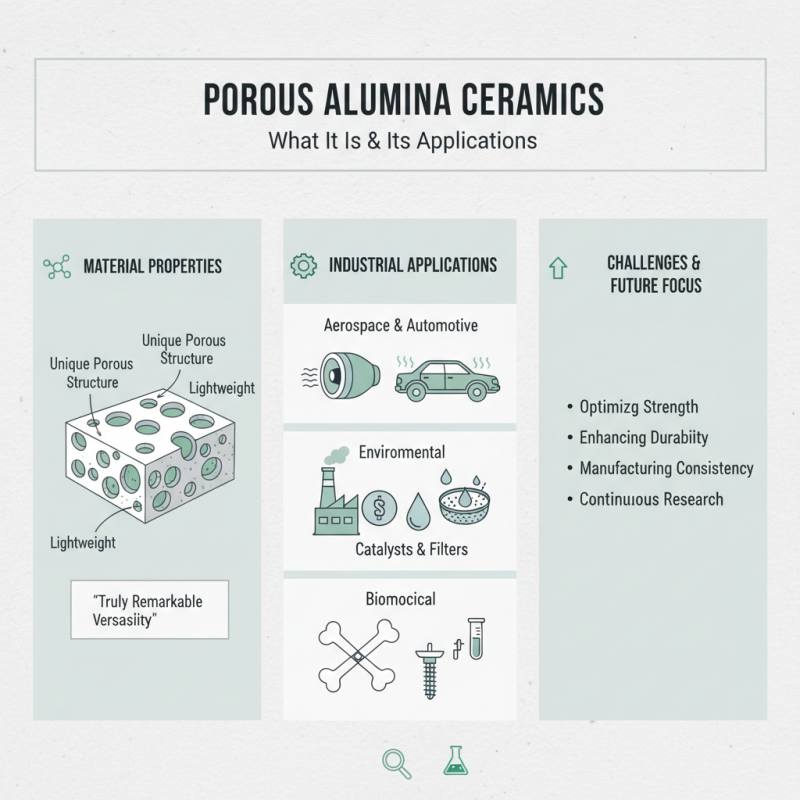

Porous Alumina Ceramics have gained significant attention in various industries. Renowned expert Dr. Emily Chang states, "The versatility of porous alumina ceramics is truly remarkable." These materials possess unique porous structures that enable various applications, from filtration to biomedical uses.

The distinct properties of Porous Alumina Ceramics make them suitable for high-temperature environments. Their lightweight design and thermal stability are assets in aerospace and automotive sectors. However, challenges remain in optimizing their mechanical strength and durability.

In the realm of environmental applications, these ceramics are used in catalysts and filters. Yet, flaws in manufacturing processes can lead to inconsistencies. Continuous research is needed to address these issues and enhance the material's performance.

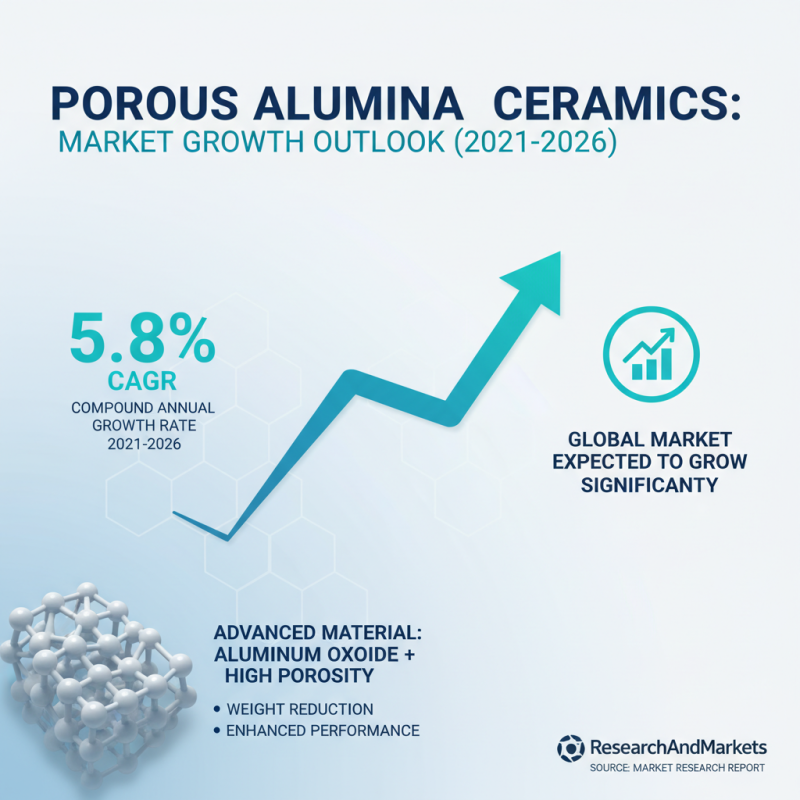

Porous alumina ceramics are advanced materials known for their unique properties. They consist of aluminum oxide with a highly porous structure. This design promotes weight reduction and enhances performance in various applications. According to a market research report by ResearchAndMarkets, the global porous alumina ceramics market is expected to grow significantly, with a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026.

These ceramics find extensive use in industries like filtration and catalysis. Their porous nature allows for efficient fluid and gas transport. For instance, they are critical in wastewater treatment plants, where they help remove contaminants. A study published in the Journal of Materials Science found that porous alumina can effectively capture heavy metals, making environments safer. However, challenges exist in manufacturing these ceramics to required standards. Variability in pore size can affect their effectiveness.

Additionally, researchers are exploring new applications for porous alumina. This includes biomedical uses, such as bone grafts and drug delivery systems. The biocompatibility has potential, yet more studies are necessary. While promising, not all porous alumina ceramics perform equally. The optimization of their properties remains a topic for further investigation in the industry.

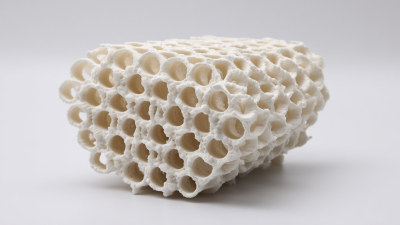

Porous alumina ceramics are known for their unique characteristics. These materials possess a high porosity, which allows them to be lightweight and highly permeable. The porous structure enhances their ability to filter and separate, making them suitable for various industrial applications. The high temperature resistance of these ceramics adds to their versatility. They can be used in harsh environments without significant degradation.

These ceramics also exhibit excellent mechanical properties. They have good strength and are chemically stable, which is crucial for many applications. The ability to withstand high temperatures while maintaining structural integrity makes them popular for thermal insulation. Many industries benefit from their properties, such as aerospace and energy production.

Tips: When working with porous alumina ceramics, consider their brittleness. They can break under stress or impact. Proper handling is key. Also, explore different grades for specific applications. The right choice can greatly influence performance. Keep in mind that the porosity level can change based on production methods, affecting overall characteristics. Understanding these factors can lead to better material selection.

Porous alumina ceramics are known for their unique properties, including high porosity and excellent thermal stability. The manufacturing of these ceramics involves various methods. One common technique is the slip casting process. In this process, a mixture of alumina powder and water is poured into a mold. The water is absorbed by the mold, leaving behind a solid structure. This method can achieve precise shapes but may generate some waste during production.

Another effective technique is gel casting. This process uses a gel polymer to bind alumina particles before shaping. Gel casting can produce highly uniform structures with controlled porosity. According to a 2022 industry report, the gel casting method enhances the mechanical strength of the final product by up to 30%. However, the complexity of gel preparation can lead to variability in results.

Furthermore, additive manufacturing techniques have gained traction. Techniques like 3D printing offer flexibility in design and customization. However, achieving the desired density and strength remains a challenge. Inadequate control of parameters like nozzle speed and temperature can lead to defects. This aspect highlights the ongoing need for optimization in manufacturing processes. Achieving consistency in porous alumina ceramics requires balancing innovation with established methods.

Porous alumina ceramics have gained significant traction in industries like filtration and catalysis. Their unique properties make them ideal for applications that require efficient separation and reaction processes. A 2021 market report highlighted a predicted growth rate of 6.5% annually in the filtration sector, driven by increasing demand for clean water and air. This growth underscores the importance of high-performance materials like porous alumina.

In the filtration industry, porous alumina ceramics serve as effective media. They exhibit high porosity and excellent chemical stability. Their ability to trap particles as small as 0.2 microns enhances operational efficiency in various water treatment facilities. Additionally, the ceramics can withstand harsh chemical environments, making them suitable for diverse applications. However, sourcing raw materials for high-quality ceramics can be challenging, leading to variability in performance.

Catalysis is another area where porous alumina ceramics excel. They provide a favorable surface for reactions. Their high surface area facilitates increased catalytic activity, essential for processes like petrochemical production. According to industry data, catalytic converters using these materials improved efficiency by up to 15%. However, the challenge remains in optimizing the pore structure for specific reactions. This optimization is critical for maximizing yield.

Porous alumina ceramics have gained attention due to their unique properties. They are lightweight and highly porous. This makes them ideal for various applications, especially in environmental and medical fields. With ongoing research, more innovative uses are emerging.

One key trend is the development of bioactive porous alumina for medical implants. Researchers are exploring how these materials can enhance bone growth. Additionally, porous ceramics are finding roles in filtration and catalysis. They can efficiently filter pollutants from air and water because of their large surface area. However, the manufacturing processes must still improve for better consistency.

Another exciting innovation is the integration of smart materials. Future porous alumina could incorporate sensors. This would allow for real-time monitoring of structural integrity. Yet, challenges remain in ensuring durability and cost-effectiveness. As the industry evolves, continuous evaluation of these materials will be crucial.

| Property | Value | Application |

|---|---|---|

| Porosity | 30-80% | Filtration Systems |

| Thermal Conductivity | 30-50 W/mK | Insulation Materials |

| Mechanical Strength | 100-300 MPa | Structural Components |

| Chemical Stability | Excellent | Chemical Processing |

| Biocompatibility | High | Biomedical Applications |

| Cost | $30-$100 per kg | Manufacturing |