Leave Your Message

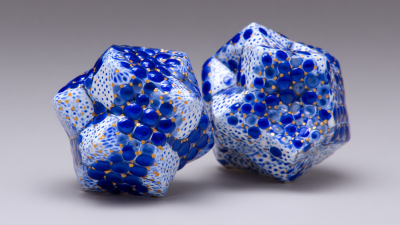

Porous Alumina Ceramics have emerged as a pivotal material in enhancing the efficiency of catalysis and filtration applications. Their unique properties, such as high surface area, chemical stability, and mechanical strength, make them ideal candidates for a variety of industrial processes. However, the integration of Porous Alumina Ceramics into these applications is not without challenges. Problems such as pore irregularity, reduced permeability, and durability issues can affect their performance and longevity. This blog aims to explore the potential and challenges associated with the use of Porous Alumina Ceramics, highlighting specific examples in catalysis and filtration. By understanding these difficulties, we can pave the way for improved designs and applications of these versatile materials, ultimately contributing to advancements in technology and environmental sustainability.

Porous Alumina Ceramics have emerged as a pivotal material in enhancing the efficiency of catalysis and filtration applications. Their unique properties, such as high surface area, chemical stability, and mechanical strength, make them ideal candidates for a variety of industrial processes. However, the integration of Porous Alumina Ceramics into these applications is not without challenges. Problems such as pore irregularity, reduced permeability, and durability issues can affect their performance and longevity. This blog aims to explore the potential and challenges associated with the use of Porous Alumina Ceramics, highlighting specific examples in catalysis and filtration. By understanding these difficulties, we can pave the way for improved designs and applications of these versatile materials, ultimately contributing to advancements in technology and environmental sustainability.

Porous alumina ceramics have gained significant traction in catalysis due to their unique structural properties and versatility in catalytic processes. Recent advancements have highlighted their role in enhancing reaction efficiencies, particularly in hydro-isomerization and cracking applications. For instance, the synthesis of amorphous silica-alumina with enhanced acidity through novel sol-gel methods has shown promising results, enabling more effective catalytic activity. Industry data indicates that the use of these materials can increase catalytic turnover rates by over 30%, making them a crucial component in modern chemical engineering.

Porous alumina ceramics have gained significant traction in catalysis due to their unique structural properties and versatility in catalytic processes. Recent advancements have highlighted their role in enhancing reaction efficiencies, particularly in hydro-isomerization and cracking applications. For instance, the synthesis of amorphous silica-alumina with enhanced acidity through novel sol-gel methods has shown promising results, enabling more effective catalytic activity. Industry data indicates that the use of these materials can increase catalytic turnover rates by over 30%, making them a crucial component in modern chemical engineering.

In the field of filtration, alumina ceramic membranes have demonstrated exceptional chemical and thermal stability, making them ideal for advanced separation processes. Recent reports suggest improvements in porosity regulation through innovative fabrication techniques, leading to higher rejection rates of contaminants. For example, tailored micro-structured ceramic beads have been effective in degrading pollutants in wastewater through advanced oxidation processes.

Tips: When selecting porous alumina ceramics for catalytic applications, consider the specific surface area and pore size, as these factors can drastically affect performance. Additionally, employing advanced fabrication techniques can enhance the characteristics of these ceramics, allowing for customization to meet specific industrial needs. Always stay updated with the latest research to incorporate state-of-the-art strategies into your processes.

Porous alumina ceramics have revolutionized air and water filtration systems due to their unique properties. With a highly porous structure, these materials allow for superior filtration efficiency, capturing contaminants as small as 0.2 microns. According to a recent report by Research and Markets, the global market for porous ceramics is expected to grow at a CAGR of nearly 10% through 2025, indicating a rising demand for advanced filtration technologies. In air purification systems, porous alumina's high surface area enhances adsorption capacity, effectively removing volatile organic compounds (VOCs) and particulate matter from the air.

When it comes to water treatment, porous alumina plays a crucial role in removing heavy metals and organic pollutants. A study published in the Journal of Environmental Management highlighted that porous alumina can reduce lead concentrations by up to 97% in contaminated water samples. This capability makes it an invaluable resource in developing sustainable filtration systems that meet regulatory standards.

Tip: To maximize the effectiveness of porous alumina in your filtration system, ensure proper maintenance and periodically replace the filters as recommended by manufacturers. This will help maintain optimal performance and extend the lifespan of your filtration setup. Additionally, consider combining porous alumina with other filtration techniques, such as activated carbon, to enhance overall efficiency.

Porous alumina ceramics have gained attention in catalysis and filtration applications due to their excellent structural stability, high surface area, and tunable porosity. A comparative analysis shows that porous alumina exhibits unique advantages over traditional catalysts, particularly in terms of catalytic efficiency and operational versatility. For instance, when utilizing alumina-supported platinum catalysts for ethanol reforming, advancements like the competitive impregnation method have been developed to achieve superior catalyst dispersion, ultimately enhancing catalytic performance.

Porous alumina ceramics have gained attention in catalysis and filtration applications due to their excellent structural stability, high surface area, and tunable porosity. A comparative analysis shows that porous alumina exhibits unique advantages over traditional catalysts, particularly in terms of catalytic efficiency and operational versatility. For instance, when utilizing alumina-supported platinum catalysts for ethanol reforming, advancements like the competitive impregnation method have been developed to achieve superior catalyst dispersion, ultimately enhancing catalytic performance.

In a recent study, the properties of alumina-supported iron-based catalysts have been compared to alternative materials for methane pyrolysis applications. This exploration highlights how various catalyst formulations can influence hydrogen production efficiency. Additionally, contrasting the dehydrogenation performances of cobalt, molybdenum, and manganese metal oxides with platinum/alumina structures reveals the nuanced trade-offs between performance and cost-effectiveness in catalyst selection.

Tip: When selecting a catalyst for specific applications, consider not only the performance metrics but also the synthesis methods and material stability.

Tip: Conduct thorough comparisons between catalysts to determine the best fit for your operational needs.

Tip: Pay attention to the influence of different support materials, as they can drastically change the catalytic behavior and overall performance.

Porous alumina ceramics have demonstrated significant advantages in environmental remediation, particularly in catalysis and filtration applications. Their structural integrity and high surface area enable effective absorption and separation processes, making them ideal materials for addressing various environmental concerns. Recent advancements in ceramic membrane technology highlight their effective utilization in wastewater treatment. These membranes offer critical benefits, including high chemical and thermal stability, which are essential in harsh operational environments.

Moreover, buried within the realm of sustainable solutions, porous alumina ceramics contribute to eco-friendly remediation methods, akin to the development of geopolymers. Both materials play a pivotal role in reducing dependencies on harmful substances, showcasing their potential in the filtration of high-temperature flue gases and the treatment of polluted water. Innovations in porous materials not only enhance traditional separation methods but also pave the way for new applications, reaffirming their status as vital components in modern environmental remediation strategies.

The development of porous alumina ceramic technologies is paving the way for innovative applications in various industrial sectors, particularly in catalysis and filtration. As industry demands evolve, these materials are being engineered to achieve higher porosity and enhanced mechanical properties. This advancement opens up possibilities for improved reaction kinetics in catalytic processes and more efficient pollutant removal in filtration systems.

One key trend is the integration of nanotechnology into the fabrication of porous alumina ceramics. By manipulating the microstructure at the nanoscale, manufacturers can enhance the surface area and optimize pore sizes for specific applications. This not only improves performance but also reduces material consumption, making processes more sustainable.

**Tip:** When sourcing porous alumina ceramics for industrial applications, consider the specific pore structure required to maximize efficiency in your process. Additionally, collaborating with suppliers who focus on innovative production methods can lead to customized solutions tailored to your needs. Evaluating the compatibility of these materials with existing processes will also ensure seamless integration and optimal results.

| Application | Key Properties | Advantages | Future Trends |

|---|---|---|---|

| Catalysis | High surface area, thermal stability | Enhanced reaction rates, durability | Nanostructured catalysts for improved efficiency |

| Filtration | Porosity, chemical resistance | Effective removal of particles, contaminants | Development of ultra-fine pore structures |

| Wastewater Treatment | Biocompatibility, structural integrity | Sustainable waste management solutions | Integration with advanced oxidation processes |

| Gas Separation | Selective permeability, high porosity | Efficient separation of gases | Development of tailored pore architectures |

| Biomaterials | Porosity, osteoconductivity | Support for bone regeneration | Customized scaffolds for tissue engineering |