Leave Your Message

In the ceramic and metallurgy industries, the term "Refractory Sagger" is crucial. These protective containers are designed to withstand extreme temperatures. Dr. Emily Chen, a leading expert in materials science, stated, “A Refractory Sagger is essential for maintaining product integrity during firing.”

The applications of Refractory Saggers are diverse, ranging from pottery to advanced ceramics. They play a pivotal role in ensuring that materials do not warp or break under high heat. However, not all saggers perform equally. The choice of materials can impact their effectiveness and lifespan.

Despite their importance, many industries overlook the significance of proper maintenance and selection. A poorly chosen Refractory Sagger can lead to costly production delays. Thus, understanding their properties and applications is vital for success in high-temperature processes. Ignoring these aspects can result in wasted resources and time.

A refractory sagger is a critical component used in high-temperature applications. It is designed to support and protect ceramic materials during firing processes. Made from durable and heat-resistant materials, a sagger can withstand extreme temperatures without deforming or breaking.

Refractory saggers come with unique characteristics. They are typically made from alumina or silica composites. This composition provides excellent thermal stability. Their construction allows them to absorb thermal shock efficiently. Properly designed, they can enhance the overall firing process, ensuring uniform temperature distribution.

**Tip:** When selecting a refractory sagger, consider its thermal conductivity. High thermal conductivity can lead to more efficient heating.

Another notable feature is their resistance to chemical attack. This makes them suitable for use in various industries. For example, they can be found in pottery, glass, or metal applications. However, not all saggers perform equally well. Some may show wear over time, affecting performance.

**Tip:** Regular inspection of saggers is recommended. Early detection of wear can prevent costly errors. Always update your inventory based on usage and wear patterns.

| Characteristic | Description |

|---|---|

| Material Composition | Typically made from alumina or other high-temperature ceramics. |

| Temperature Resistance | Able to withstand temperatures above 1300°C (2372°F). |

| Applications | Used in the firing of ceramics, glass production, and metallurgy. |

| Shape and Design | Available in various shapes including plates, trays, and custom designs. |

| Durability | High durability under extreme conditions, reducing wear and tear. |

| Thermal Shock Resistance | Resistant to rapid temperature changes which prevents cracking. |

| Cost Efficiency | Long lifespan can lead to cost savings in high-volume production. |

Refractory saggers are essential in high-temperature applications. They support materials during firing processes. These structures must withstand extreme conditions. The right materials are crucial for their effectiveness.

Common materials used in refractory sagger manufacturing include alumina, silica, and fire clay. Alumina is known for its high melting point. Silica contributes to thermal stability. Fire clay is often chosen for its plasticity and strength. Mixing these materials requires careful attention. The proportions can influence the final product's performance.

Some saggers face issues like thermal shock or wear. These challenges arise from improper material choices. Addressing these problems demands ongoing research and innovation. The balance of strength and thermal resistance is vital. Ultimately, the materials selected can dictate the success of refractory saggers in industrial applications.

Refractory saggers are essential in various industrial processes. These durable containers hold materials at high temperatures. They prevent contamination and protect products during firing. Commonly found in ceramics, glass, and metal industries, saggers offer a reliable way to manage heat.

In the ceramics industry, for example, saggers support pottery during firing. They can withstand extreme conditions. However, they may wear down over time. It's crucial to regularly inspect and replace them to avoid product defects. A small crack can lead to a big problem in the final product.

Tips: Always check for signs of wear. Look for cracks or discoloration. Address issues promptly to maintain quality.

In the glass industry, saggers play a vital role in shaping glass products. They help in achieving uniform heating. Yet, improper use can lead to uneven results. Operators must understand how to load saggers correctly for optimal outcomes.

Tips: Ensure even loading of materials. Avoid overcrowding saggers to allow for proper airflow. This simple adjustment can enhance productivity.

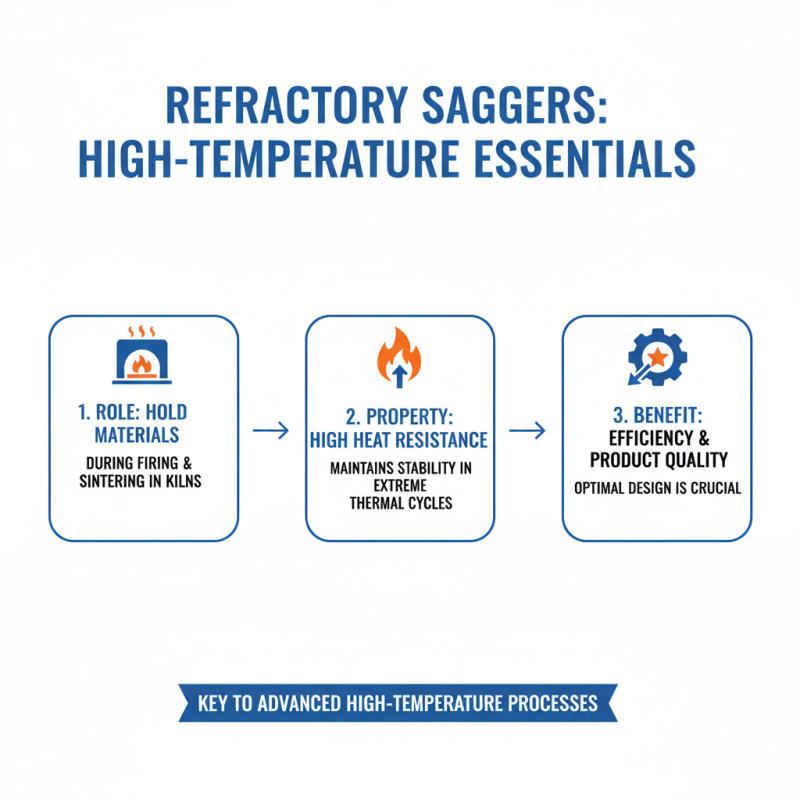

Refractory saggers are essential in high-temperature processes. They hold materials during firing and sintering in kilns. Their high resistance to heat helps maintain stability. This is crucial during intense thermal cycles. With the right design, saggers can improve efficiency and product quality.

Using refractory saggers offers significant benefits. They reduce contamination risk. Sagger materials are inert, preventing unwanted reactions. This is especially important in ceramics and metal industries. The durability of these saggers also contributes to lower maintenance costs. They withstand harsh conditions without failure.

Tip: Always inspect your saggers regularly for signs of wear. This can prevent unexpected issues in high-temperature operations. Another consideration is the type of refractory materials used. Not all saggers suit every process. Make sure to evaluate your specific needs carefully.

Refractory saggers are essential in high-temperature processes. They provide support and protection to ceramic products during firing. Proper maintenance ensures optimal performance and longevity. Many industries rely on these saggers, including ceramics and glass manufacturing. A study by the International Ceramics Society indicates that well-maintained refractory saggers can last up to 30% longer than neglected ones.

Routine inspections are vital. Check for cracks, warping, or signs of wear regularly. Cleaning is equally important. Residue can compromise their integrity and efficiency. Experts recommend a cleaning schedule every few weeks, depending on usage. An industry survey found that 40% of users reported improved product quality after implementing a strict maintenance routine for saggers.

Documentation can be a challenge. Keeping track of maintenance records is often overlooked. It is essential for identifying patterns and preempting failures. Some facilities lack clear guidelines for handling saggers. This leads to inconsistencies in care and frequent replacements. A reflective approach to maintenance can improve reliability and reduce costs.