Leave Your Message

Porous Alumina Ceramics are gaining traction across various industries. Dr. Emily Chen, a noted expert in advanced ceramics, emphasizes, "Porous Alumina Ceramics are revolutionizing how materials are used in engineering applications." This highlights the material's unique properties and potential.

The versatility of Porous Alumina Ceramics makes them suitable for filtration, catalysis, and even biomedical applications. With advancements in production techniques, we see enhanced performance and customized solutions. This material's high porosity allows for efficient fluid flow, which is crucial in many industrial processes.

However, challenges remain. Issues with mechanical strength and processing costs can hinder broader adoption. Companies must consider these factors to fully leverage the benefits of Porous Alumina Ceramics. Continued research and innovation are essential for overcoming these obstacles and maximizing their industrial impact.

Porous alumina ceramics are gaining traction in the aerospace industry. Their lightweight nature makes them ideal for reducing overall aircraft weight. According to a recent industry report, the global aerospace ceramics market is projected to grow to $2 billion by 2026. This growth reflects the increasing demand for advanced materials that offer durability and thermal resistance.

One key application is in thermal protection systems. These ceramics can withstand high temperatures, making them crucial for components exposed to extreme conditions. Some manufacturers have noted that porous alumina can reduce thermal conductivity by up to 70%. This property helps protect sensitive components and enhances overall safety.

However, there's a learning curve. Not all porous alumina ceramics meet the rigorous standards set by the aerospace sector. Quality control remains a challenge. Researchers state that inconsistencies in pore structure can affect mechanical performance. This area will need more focused efforts to ensure reliability in critical applications.

Porous alumina ceramics have gained immense traction in the medical field. Their biocompatibility makes them ideal for implantable technologies. Doctors use these materials in bone grafts and dental implants. The open pore structure allows for cell growth and nutrient flow. This enhances healing and integration with tissues.

When considering porous alumina for medical devices, focus on manufacturing processes. The production must adhere to strict standards. Inconsistent pore sizes can impact performance. A balance between porosity and strength is essential. It's not just about using the material; it’s about optimizing it for specific applications. Poorly designed implants can lead to complications. Reflecting on manufacturing flaws helps in enhancing overall quality.

**Tips:** Always consult with material scientists during the design phase. Regular testing can reveal flaws early in production. Consider the long-term effects of the implanted material on the human body. This oversight could save lives.

Porous alumina ceramics play a pivotal role in modern filtration systems. Their unique structure allows for effective particle removal in water and air purification. According to a recent industry report, nearly 50% of water treatment processes utilize advanced ceramic materials. This highlights the growing trend towards sustainable filtration solutions.

In air purification, porous alumina ceramics enhance the removal of volatile organic compounds (VOCs). A significant study indicated that these materials can reduce VOC levels by up to 90%. This efficiency is crucial in various industries, where clean air is mandated. However, challenges remain in scaling up production and ensuring consistent quality. Variability in porous structure can lead to inconsistent filtration performance.

Moreover, while the benefits are clear, the environmental impact of ceramic production cannot be ignored. High energy consumption during manufacturing raises concerns about sustainability. Continuous innovation in production methods is necessary. This requires a balance between efficiency and environmental responsibility. The future of porous alumina ceramics in filtration systems is promising, but it calls for critical examination and improvements.

Porous alumina ceramics play a significant role in catalysts and chemical processing. Their unique structure allows them to maximize surface area and enhance reactions. This feature is crucial in catalytic converters, where efficiency is essential.

In chemical processing, these ceramics serve various functions. They can act as supports for catalysts, improving reaction rates and product yields. Their thermal stability is impressive, allowing them to withstand harsh environments. However, optimizing their properties can be challenging. Variations in pore size may affect their performance.

The integration of porous alumina in industry remains an area of exploration. Researchers constantly seek to improve their functionalities. While progress has been made, some applications still face limitations. Finding the balance between cost-effectiveness and performance is vital. Thus, further inquiry is necessary to unlock their full potential.

The chart below illustrates the top applications of porous alumina ceramics in catalysts and chemical processing, showcasing the percentage distribution across various industries in 2026.

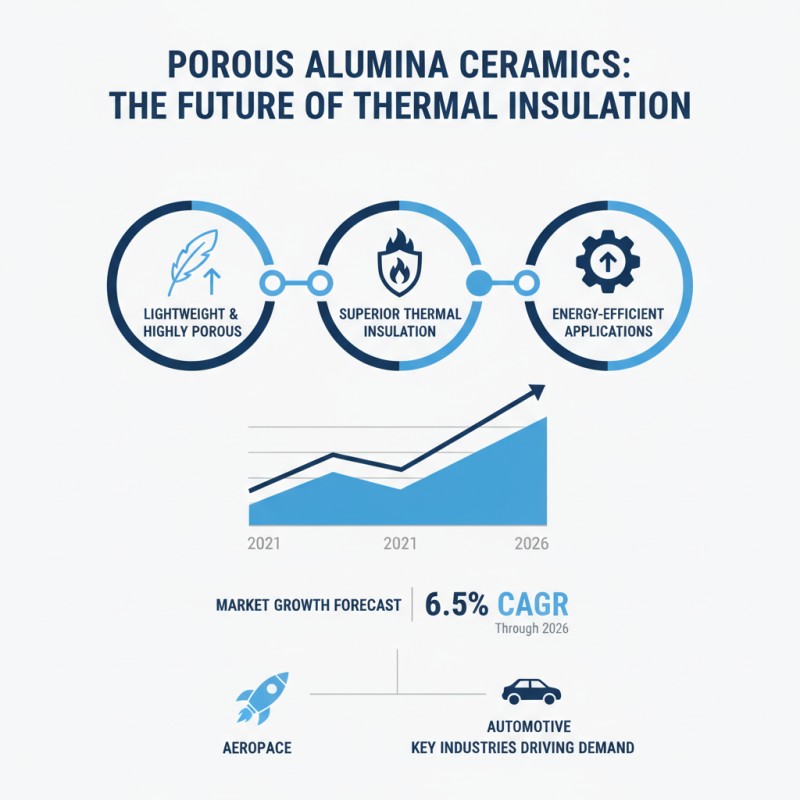

Porous alumina ceramics are gaining traction in various industries, especially for their thermal insulation capabilities. They are lightweight and highly porous, making them ideal for energy-efficient applications. Recent industry reports show that the market for advanced ceramics is estimated to grow at a CAGR of 6.5% through 2026. This growth is driven by demands for better thermal management solutions in sectors such as aerospace and automotive.

The high thermal stability of porous alumina ceramics allows them to withstand extreme temperatures without compromising performance. For instance, their thermal conductivity can be as low as 0.08 W/mK, making them superior insulators compared to traditional materials. However, some challenges persist. The brittleness of these materials can lead to issues during fabrication and installation. Companies must invest in innovative engineering solutions to mitigate these drawbacks while optimizing performance.

Moreover, energy efficiency is becoming a critical factor in regulatory compliance. The push for greener technologies is evident in the significant investments in research and development. A notable statistic reveals that adopting insulation materials like porous alumina could reduce energy consumption by up to 30%. Nevertheless, the cost of production remains a concern, posing a barrier to widespread adoption. Industry stakeholders must address these issues to unlock the full potential of porous alumina ceramics in enhancing thermal insulation solutions.