Leave Your Message

In the realm of high-temperature applications, the significance of selecting the appropriate materials cannot be overstated. Among these materials, the Cordierite Mullite Sagger stands out for its exceptional thermal stability, low thermal expansion, and excellent resistance to thermal shock. These properties make it an ideal choice for various industrial processes, particularly in ceramic and glass production, where precision and efficiency are paramount. As manufacturers seek ways to enhance their operational efficiency while reducing costs, understanding the nuances of Cordierite Mullite Saggers becomes crucial. This guide aims to unlock the potential of Cordierite Mullite Saggers, exploring their types, advantages, and applications, and providing insights into how they can transform high-temperature manufacturing processes. By delving into this topic, readers will gain a comprehensive understanding of how these innovative materials can drive performance and reliability in demanding environments.

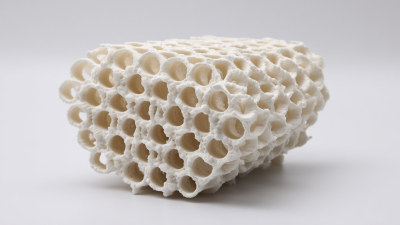

Cordierite mullite saggers have become essential in high-temperature applications, offering unique properties that enhance their performance and longevity. These materials, a composite of cordierite and mullite, exhibit remarkably low thermal expansion and excellent thermal shock resistance. According to a study published by the International Journal of Applied Ceramic Technology, cordierite-based materials show a thermal expansion coefficient of approximately 3.0 x 10^-6/°C, making them ideal for environments that undergo significant temperature fluctuations.

Another critical property of cordierite mullite saggers is their high resistance to deformation under heat, which allows them to maintain structural integrity at temperatures exceeding 1400°C. A report by the American Ceramic Society highlights that these saggers can endure prolonged exposure to temperatures typical in ceramics processing without significant wear or degradation. This stability not only enhances their utility but also contributes to energy savings and reduced maintenance costs in industrial settings, underscoring the efficiency advantages of using cordierite mullite in high-temperature applications.

Cordierite mullite saggers have emerged as a game-changer in high-temperature industrial applications due to their unique properties. These saggers not only withstand extreme temperatures but also provide a range of advantages that enhance efficiency in manufacturing processes. One of the top benefits is their excellent thermal shock resistance, ensuring they perform reliably under rapid temperature changes. Additionally, cordierite's low thermal conductivity contributes to energy savings, offering financial advantages to operations.

When considering the implementation of cordierite mullite saggers, keep in mind a few tips for maximizing their benefits. First, ensure that the saggers are tailored to the specific requirements of your application; this might include accounting for factors like load capacity and temperature stability. Secondly, proper maintenance and handling are crucial to prolonging their lifespan; investing in training for staff on best practices can mitigate wear and damage. Lastly, monitor the performance regularly to identify any changes that could indicate the need for replacement or adjustment, keeping your process efficient and cost-effective.

When selecting the right Cordierite Mullite Sagger for high-temperature applications, understanding your unique needs is paramount. The versatility of Cordierite Mullite is critical for maintaining efficiency in demanding environments. Consider factors such as size, thermal shock resistance, and thermal conductivity when choosing a sagger that aligns with your operational requirements. Just as diverse consumer demands shape product offerings in various marketplaces, identifying the specific parameters that your application requires will help streamline your selection process.

Additionally, as industries evolve toward more customized solutions, it becomes essential to integrate flexibility into your decision-making. Whether you need a standard size for bulk production or a specialized design for custom projects, a tailored approach can significantly enhance performance outcomes. This mirrors the trend in flexible workspace solutions that cater to varying needs, highlighting the importance of adaptability in today’s fast-paced landscape.

By focusing on both standard specifications and unique requirements, you can ensure that your choice of Cordierite Mullite Sagger enhances efficiency and meets the challenges of high-temperature applications effectively.

In the quest for efficiency in high-temperature applications, Cordierite Mullite Saggers have emerged as an indispensable tool. These advanced materials are specifically designed to withstand extreme temperatures while maintaining structural integrity, making them a preferred choice in industries such as ceramics and metallurgy. By utilizing innovative techniques, manufacturers can enhance the performance of these saggers, ultimately leading to reduced energy consumption and improved output.

One effective method to maximize the efficiency of Cordierite Mullite Saggers is through image-based defect detection. By implementing machine learning algorithms to identify defects in real-time, manufacturers can proactively address issues that might compromise the quality of their products. Additionally, incorporating augmented reality in training processes can allow operators to visualize complexities in handling and maintaining these saggers, further enhancing operational efficiency.

For those looking to optimize their processes, here are a couple of tips: First, routinely audit your production line for defects using advanced imaging technologies to ensure only high-quality saggers are used. Second, consider investing in training that incorporates modern technologies like virtual simulations to better equip your team in handling these materials. By embracing such innovations, industries can unlock new levels of efficiency and sustainability in their operations.

Cordierite mullite saggers are essential components in high-temperature applications, especially in the ceramics and refractory industries. To extend their lifespan and maintain operational efficiency, following best maintenance practices is crucial. According to a report by the International Ceramics Association, proper care can increase the lifespan of these saggers by up to 40%. This extension not only reduces production costs but also minimizes material waste, thus enhancing overall sustainability in production processes.

Regular inspections and cleaning are pivotal in maintaining cordierite mullite saggers. Industry standards suggest that scheduled maintenance every 500 heating cycles can significantly mitigate the risk of structural failure. Additionally, temperature management plays a critical role; ensuring that heating ramps are gradual can prevent thermal shock, which is a common cause of premature saggers' failure. By implementing these practices, manufacturers can enjoy better product yield and operational uptime, ultimately contributing to improved profitability in high-temperature environments.

| Parameter | Description | Recommended Value |

|---|---|---|

| Max Operating Temperature | Temperature at which the saggar can perform optimally | 1350°C |

| Thermal Shock Resistance | Ability to withstand sudden changes in temperature | Needle test after 1200°C |

| Chemical Stability | Resistance to chemicals at high temperatures | High |

| Average Lifespan | Expected duration of usage before replacement | 3-5 years |

| Maintenance Frequency | Recommended check-up intervals | Every 6 months |

| Weight | Average weight for standard saggers | 5-7 kg |

| Moisture Absorption | Amount of water that can be absorbed | < 1% |