Leave Your Message

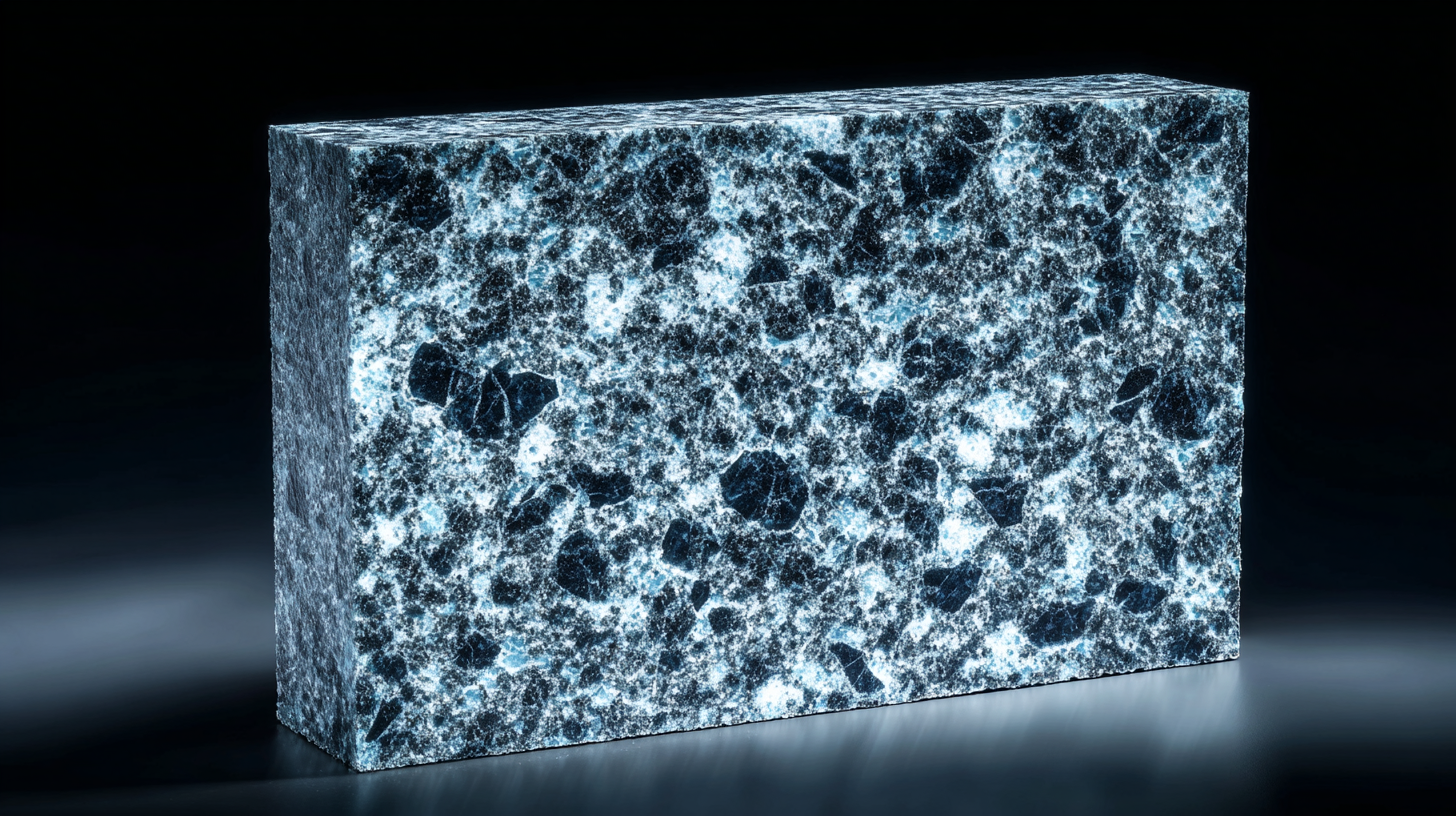

The exploration of Corundum Mullite Plate has garnered significant attention in modern industries due to its exceptional properties and versatile applications. This unique material, characterized by its high thermal stability, low thermal conductivity, and excellent mechanical strength, plays a crucial role in various sectors such as manufacturing, aerospace, and metallurgy. By understanding the inherent qualities of Corundum Mullite Plate, businesses can harness its capabilities to optimize processes, enhance product performance, and achieve greater economic efficiency. This article aims to delve into the distinctive features of Corundum Mullite Plate while offering practical tips for its effective utilization in different industrial applications. As industries continue to evolve, the integration of advanced materials like Corundum Mullite Plate can pave the way for innovations that redefine manufacturing standards and performance benchmarks.

Corundum mullite plates exhibit remarkable physical and chemical properties that make them indispensable in various industrial applications. Their high melting point and excellent thermal shock resistance allow them to withstand extreme temperatures, which is critical for sectors such as aerospace and automotive manufacturing. These plates also exhibit low thermal conductivity, making them highly efficient insulators. Additionally, their mechanical strength ensures durability and longevity in demanding environments, thereby reducing maintenance costs and enhancing operational efficiency.

Moreover, corundum mullite plates are highly resistant to chemical corrosion, making them suitable for use in industries that involve harsh chemical processes. This property is particularly beneficial in the production of metal alloys and glass ceramics, as these materials require stable substrates that can withstand intense reactive conditions. As industries continue to seek materials that can enhance performance while minimizing environmental impact, corundum mullite plates are poised to play a crucial role in the evolution of modern manufacturing processes. Their unique properties align well with the growing demand for high-performance ceramics, underscoring their potential in the global market.

Corundum mullite plates are emerging as vital materials in high-temperature industrial applications due to their outstanding thermal and mechanical properties.

These plates are particularly valued in sectors that require exceptional durability and thermal stability, such as aerospace, metallurgy, and ceramics.

The recent advancements in alumina/aluminum titanate ceramic composites highlight their ability to withstand extreme conditions without compromising structural integrity.

This makes corundum mullite plates an ideal choice for applications that demand high performance under thermal stress.

Tips: When selecting materials for high-temperature applications, always consider the specific thermal and mechanical requirements of your project.

Incorporating materials like corundum mullite can lead to significant improvements in product longevity and efficiency.

Furthermore, ongoing research into the synthesis of refractory ceramics from industrial waste points to a sustainable path forward for the usage of corundum mullite in modern industry.

This not only enhances the performance of the materials but also reduces environmental impact.

The trend towards utilizing natural and recycled resources will likely drive further innovation in the field, ensuring that corundum mullite continues to play a pivotal role in high-temperature applications for years to come.

Tips: Explore the potential of recycled materials in your processes; you may discover innovative solutions that reduce costs while enhancing performance.

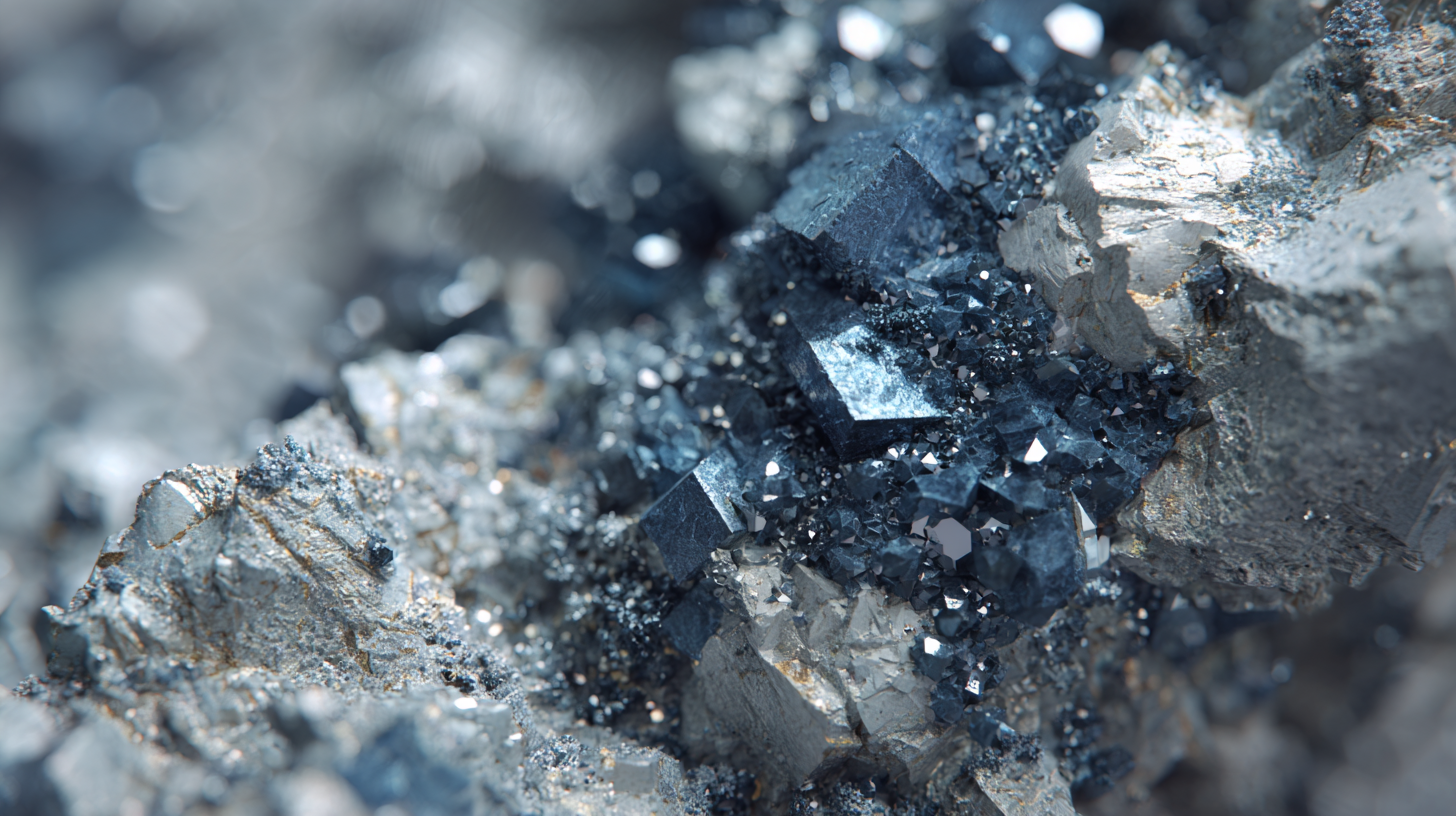

Corundum mullite plates have garnered attention in advanced ceramics due to their exceptional thermal stability and mechanical properties. Specifically, a comparative analysis of corundum mullite with other advanced ceramic materials reveals distinct advantages in terms of density and microstructural characteristics. Calibrated studies indicate that zirconium-doped calcium hexaaluminate (CA6), with a structural formula of CaAl11.73◊0.25Zr0.02O18.41◊0.59, exhibits enhanced density, indirectly improving its potential applications in demanding environments.

Notably, the apparent porosity and bulk density of corundum-mullite samples, which are fired at varying temperatures, highlight crucial performance metrics. Research indicates that as firing temperature increases, both the apparent porosity decreases and the bulk density improves, thus aligning with industry demands for more resilient and less porous materials.

**Tips:** When selecting materials for high-temperature applications, prioritize those with low porosity and high density, as these characteristics significantly enhance durability. Additionally, consider the specific microstructural features of materials, as they can greatly influence fracture behavior in operational conditions. Understanding these parameters will aid in making informed decisions for industrial applications.

| Material | Density (g/cm³) | Thermal Conductivity (W/m·K) | Max Service Temperature (°C) | Applications |

|---|---|---|---|---|

| Corundum Mullite | 3.0 | 20-30 | 1600 | Refractory linings, kiln furniture |

| Alumina | 3.95 | 30-40 | 1700 | Ceramics, electrical insulators |

| Silicon Carbide | 3.21 | 120-150 | 2000 | Abrasives, armor |

| Zirconia | 6.05 | 2.5-3.5 | 2400 | Dental ceramics, fuel cells |

| Silica | 2.65 | 1.4 | 1700 | Glass, ceramics |

The production of corundum mullite plates presents unique sustainability challenges and opportunities within modern industry. This advanced material, known for its high thermal stability and mechanical strength, is increasingly favored in high-temperature applications. However, the environmental impact of its production process necessitates a critical examination. Efforts to source raw materials sustainably, coupled with innovations in manufacturing techniques, can mitigate negative effects on ecosystems. Utilizing recycled alumina and silica not only conserves resources but also reduces energy consumption associated with extraction and processing.

Moreover, incorporating renewable energy sources into the production processes of corundum mullite plates enhances sustainability. By transitioning to solar, wind, or other renewable energy techniques, manufacturers can significantly decrease their carbon footprint. Additionally, the durability of corundum mullite plates contributes to a longer product lifespan, which reduces waste and the need for frequent replacements. Overall, the commitment to sustainable practices in the production of corundum mullite plates not only benefits the environment but also aligns with the growing demand for eco-friendly materials in various industries.

The innovative landscape of corundum mullite technology is witnessing significant advancements, particularly in high-purity mullite powder applications. As industries increasingly demand materials that can withstand extreme temperatures and serve diverse functions, corundum mullite is emerging as a crucial solution. The high-purity mullite powder market, projected to embark on a growth trajectory starting from USD 195.2 million in 2025, highlights the ascending interest in this versatile material. It serves as a vital component in refractory products, ceramics, and various high-performance applications.

Emerging technologies in corundum mullite production not only enhance material properties but also expand its industrial applications. Innovations in synthesis methods and improvements in purity levels are setting new benchmarks for performance, making corundum mullite an ideal choice for both traditional and novel applications. As market trends lean towards sustainability and efficiency, corundum mullite’s role in high-temperature environments positions it as a key player in the future of material science, promising to meet the evolving needs of modern industries.