The Versatile Applications of Alumina Ceramics in Modern Industries

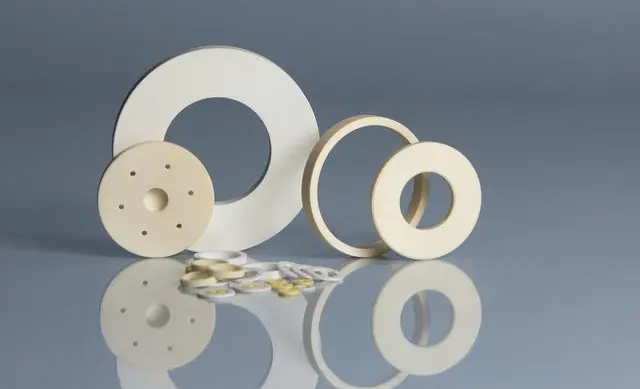

Alumina ceramics, also known as aluminum oxide ceramics, have gained significant attention in various industries due to their exceptional properties and versatility.

The Essential Role of Refractory Kiln Furniture in Modern Ceramics

In the world of ceramics, the application of refractory Kiln Furniture is a critical aspect that often goes unnoticed. Refractory kiln furniture refers to the various supports, shelves, and props made from heat-resistant materials that are used within kilns during the firing process.

Silicon Carbide Kiln Furniture: Empowering Efficiency and Quality in Pottery Firing

The creation of pottery – encompassing functional earthenware, decorative stoneware, and art pieces – relies heavily on controlled firing within kilns. While often unseen, the kiln furniture (saggars, setters, posts, shelves) plays a critical role in this process. Silicon Carbide (SiC) has become the material of choice for advanced pottery studios and manufacturers, offering transformative advantages over traditional refractory ceramics like cordierite or mullite, directly impacting both artistic outcomes and operational efficiency.

Cordierite Ceramics: Engineered for Thermal Resilience

Cordierite, a magnesium aluminosilicate mineral (nominal composition Mg₂Al₄Si₅O₁₈), forms the basis of a unique class of Technical Ceramics prized primarily for its exceptional resistance to thermal shock. When processed into ceramic components via sintering, cordierite exhibits a combination of properties that make it indispensable in demanding high-temperature environments.

The Role and Characteristics of Refractory Saggers in Pigment Sintering

In the high-temperature crucible of pigment manufacturing, particularly for demanding inorganic pigments used in ceramics, glass, and specialty applications, the Refractory Sagger (saggaring box) plays an indispensable, often understated role.

Extrusion Molding of Cordierite Kiln Furniture: Methods, Characteristics, and Applications

Introduction:

Cordierite (2MgO·2Al₂O₃·5SiO₂) kiln furniture, essential components in high-temperature ceramic and metallurgical industries, is predominantly manufactured via extrusion molding. This process efficiently produces complex, lightweight, and highly durable shapes like setters, saggers, beams, and posts, crucial for supporting ware during firing cycles.

Ceramic Cuplocks: Features and Applications

Ceramic cuplocks are specialized components widely used in scaffolding systems, offering superior durability, stability, and safety. These cuplocks are typically made from high-strength ceramic materials, ensuring excellent resistance to wear, corrosion, and extreme weather conditions. Their unique design allows for quick and secure connections between scaffold tubes, making them a preferred choice in construction and industrial applications.

The Multifaceted Role of Alumina Ceramic Plates in Powder Metallurgy Manufacturing

Within the intricate processes of powder metallurgy (PM), where metal powders are transformed into complex, high-performance components, alumina (aluminum oxide, Al₂O₃) ceramic plates serve as indispensable, high-performance workhorses. Their unique combination of properties makes them uniquely suited to withstand the demanding conditions encountered throughout the PM production chain, significantly contributing to process efficiency, dimensional accuracy, part quality, and overall equipment longevity.

Kiln Furniture for Vacuum Furnaces: The Silent Workhorses of High-Temperature Processing

Kiln Furniture for Vacuum Furnaces: The Silent Workhorses of High-Temperature Processing

Within the controlled, airless environment of a vacuum furnace, achieving precise thermal processing relies heavily on a critical, yet often understated, component: kiln furniture. These are the structural supports, setters, boats, trays, and other fixtures that hold, protect, and position the workload during heating, soaking, and cooling cycles. Unlike their counterparts in atmospheric furnaces, kiln furniture operating in vacuum faces a unique set of demands, making material selection, design, and maintenance paramount for successful and efficient operations.

Refractory Kiln Furniture in Industrial Furnaces: An Overview

In industrial thermal processing, kiln furniture—comprising various refractory components designed to support, protect, and transport materials during high-temperature operations—plays a critical role in ensuring efficient and reliable furnace performance. These components must withstand extreme temperatures (often exceeding 1600°C), rapid thermal cycling, mechanical stress, and chemical corrosion, all while maintaining structural integrity. This article explores the types, materials, and applications of refractory kiln furniture, emphasizing their significance in industries such as ceramics, metallurgy, glassmaking, and advanced materials manufacturing.