Ceramic Diaphragm for Removing Chrome: A Revolutionary Solution

In the realm of industrial applications, the need for effective and efficient methods to remove chrome from various surfaces has become increasingly important. One innovative solution that has emerged is the use of a ceramic diaphragm specifically designed for this purpose. This technology not only enhances the removal process but also ensures environmental safety and sustainability.

Corundum-Mullite: Performance and Application Analysis

Corundum-mullite is a composite material formed by the reaction of corundum (Al₂O₃) and mullite (3Al₂O₃·2SiO₂) at high temperatures. Its chemical formula is typically Al₄Si₂O₁₃, made up of varying proportions of corundum and mullite. This unique combination gives corundum-mullite excellent stability and performance at high temperatures.

- Corundum (Corundum): Made primarily of aluminum and oxygen, corundum is an extremely hard mineral (Mohs hardness 9), known for its excellent high-temperature resistance and chemical stability.

- Mullite (Mullite): A silicate mineral containing aluminum and silicon, mullite is famous for its low thermal expansion and good thermal shock resistance, making it commonly used in high-temperature ceramics.

How to Enhance the Wear Resistance of Mullite saggers

Mullite saggers are essential components in the ceramics industry, particularly in the firing process of porcelain and other high-temperature materials. Their ability to withstand extreme conditions makes them invaluable; however, enhancing their wear resistance is crucial for improving their longevity and performance. Here are several strategies to enhance the wear resistance of mullite saggers.

Silica Bonded Silicon Carbide Kiln Furniture: The Future of High-Temperature Applications

In the realm of high-temperature applications, the choice of kiln furniture is crucial for achieving optimal performance and durability. Among the various materials available, silica bonded Silicon Carbide Kiln Furniture has emerged as a leading option, thanks to its unique properties and advantages.

Mullite Ceramics: Its Properties, Structure, and Synthesis

Mullite, a relatively rare mineral in nature, is characterized by its good thermal, electrical, and properties. As a result, it has found extensive use in traditional and advanced industries, including ceramics, refractories, and foundries. Notably, mullite is the only crystalline phase in the aluminosilicate system that is stable in a wide range of compositions and temperatures.

What is cordierite ceramic ?

Cordierite is a man-made refractory low thermal expansion crystalline solid that forms at very high temperatures (in the right mix of kaolin and talc).

We are on Shanghai exhibition for Powder metallurgy, cemented carbides and advanced ceramics

The exhibition is held from Mar 10 to 12th.It is for Powder metallurgy,cemented carbides and adbanced ceramics.

Application of refractory materials in modern production

Refractory materials refer to materials that can maintain their shape and performance under high temperature environments. They are widely used in many industrial fields such as metallurgy, ceramics, glass, cement, etc. With the continuous advancement of modern production technology, the application of refractory materials has become increasingly widespread and has become an indispensable and important part of modern industry.

99% Alumina ceramic's application

99% alumina ceramic, known for its exceptional hardness and durability, has become a material of choice in various industries. This high-purity ceramic is composed primarily of aluminum oxide (Al2O3), which contributes to its impressive mechanical properties, thermal stability, and resistance to wear and corrosion. As a result, 99% alumina ceramic finds extensive applications across multiple sectors.

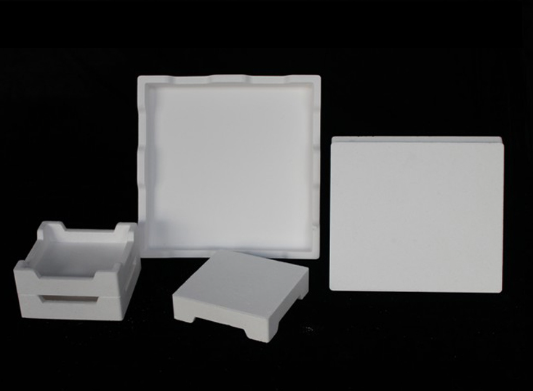

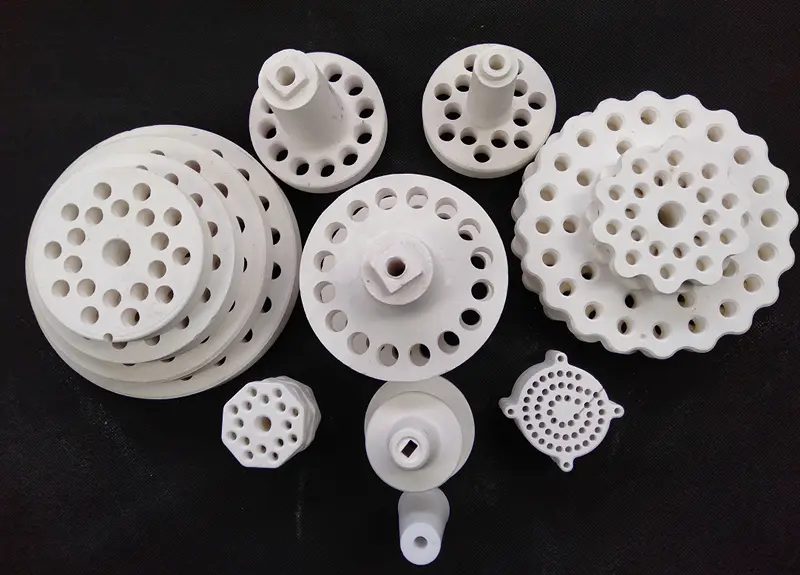

Refractory Saggar: Applications in Powder Firing

Refractory saggars are essential components in the ceramics and metal industries, particularly in processes involving high-temperature firing. These specialized containers are designed to protect delicate items during firing, ensuring that they maintain their integrity and quality. One of the most significant applications of refractory saggars is in powder firing, where they play a crucial role in achieving optimal results.