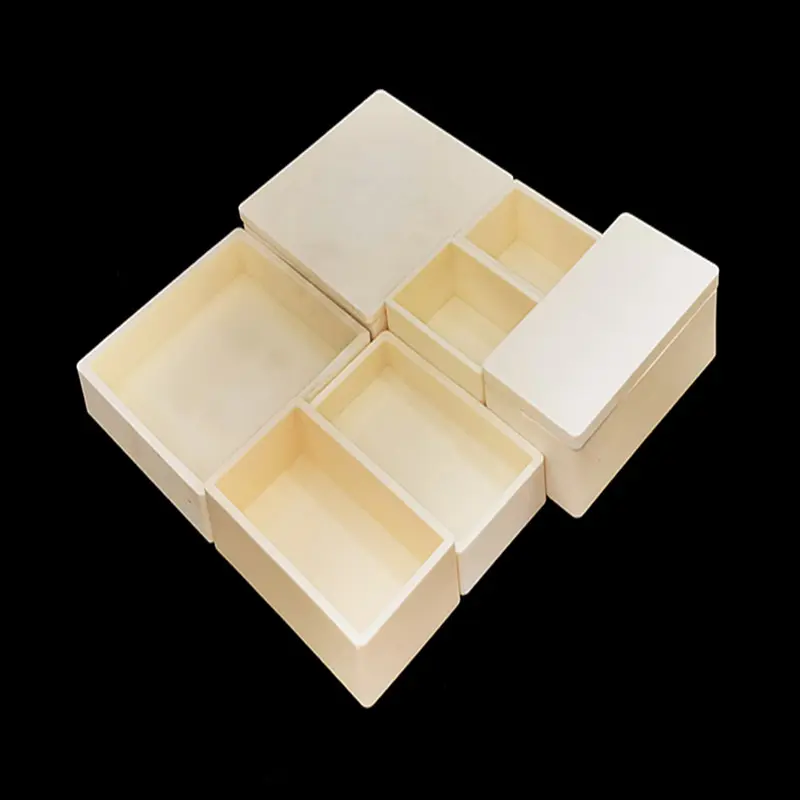

High Heat And High Temperature Resistance Alumina Ceramic Sagger

Product Feature

● High purity: Al203> 99%, Good chemical resistance

● Good temperature resistance: Long-term use in 1600°C, short-term in 1800°C

● Good resistance to rapid cooling and rapid heating, not easy to burst

● Slip casting and high density

● Various kinds of shapes and sizes

Product Parameter

|

Unit |

95% |

99% |

|

|

Density |

g/cm3 |

3.6 |

3.8 |

|

Water absorption |

% |

<0.4 |

<0.2 |

|

Firing temperature |

°C |

1600 |

1800 |

|

Hardness |

HRA |

70 |

80 |

|

Coefficient of linear expansion |

*10-6/°C |

5.5 |

5.3 |

|

Dielectric constant |

|

9 |

10.5 |

|

Volume resistivity |

Ω·cm |

— |

1013 |

|

Breakdown voltage |

KV/mm |

14 |

15 |

|

Breaking strength |

Mpa |

250 |

300 |

Precautions For The Use Of Alumina crucible

Various Laboratory Metal Analysis

Shuttle Kiln Burning Pigment

● Preheating and cooling :

Before using the alumina cruciblemust be preheated to prevent the damage of the crucible cauby rapid temperature change. Similarly, a slow cooling proce!also required after use to prevent the sudden loss of heat frorcausing damage to the crucible.

● Avoid collision :

Alumina crucible is relatively fragile, avoid cwith hard objects, in order to prevent breakage affecting theexperiment.

● Cleaning method :

Clean it after use to avoid residue affectinext experiment.

Product Application

Laboratory Fumace

Melting Optical Glass

Melting Metal

Analysis Of Mineral Raw Materials

Product Detail

Our Advantage

● Many grades of ceramic materials to choose from for your applications.

● Technical support on consultation, design, and prototypes.

● Fast delivery from prototype to production quantities.

● In-house capabilities in forming, sintering, machining, glazing, metalizing, brazing, and assembly.

● Our highly trained team of quality assurance staff uses advanced measuring devices to ensure that our products always meet the customers' requirements.

FAQ

-

1. What are your prices ?

-

2. Do you have a minimum order quantity ?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website. -

3. Can you supply the relevant documentation ?

-

4. What is the average delivery time ?

-

5. What kinds of payment do you accept ?