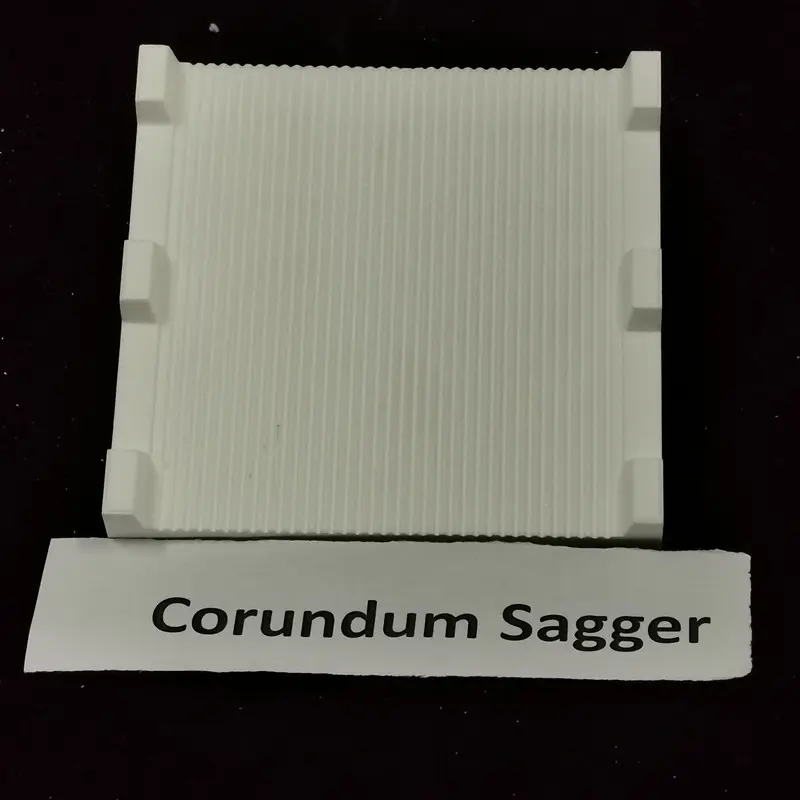

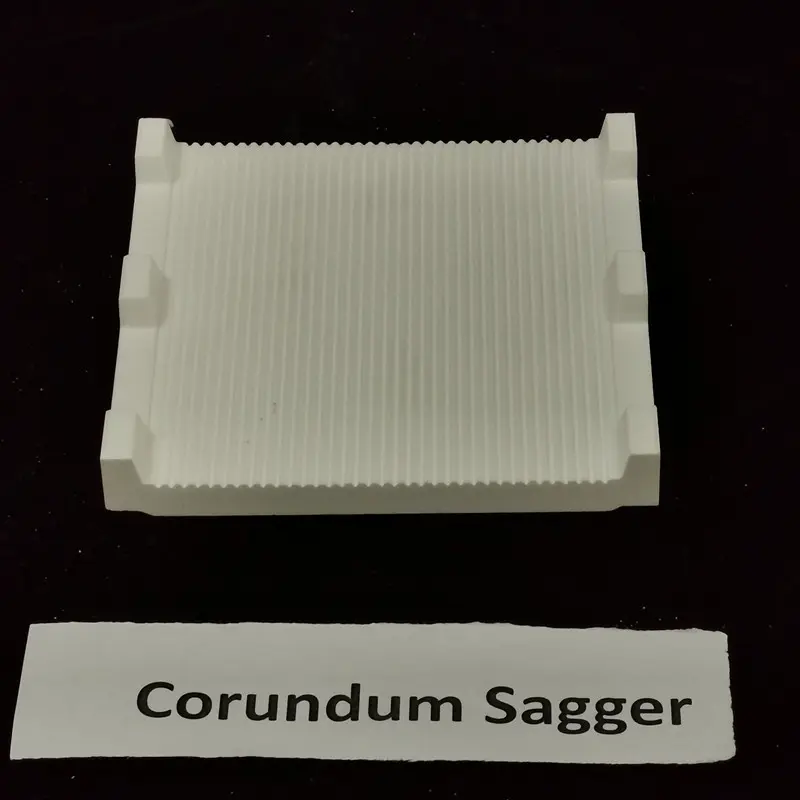

High-Performance Kiln Furniture Stackable Corundum Saggers for Industrial Firing

2. Material Properties and Performance

2.1 Corundum Composition

-

High Purity Alumina (99–99.7% Al₂O₃): Minimizes contamination during firing.

-

Density (3.8–4.0 g/cm³): Enhances thermal shock resistance and load-bearing capacity.

-

Crystalline Structure: α-phase corundum ensures stability up to 1800°C.

2.2 Key Performance Metrics

-

Thermal Shock Resistance: Withstands rapid cooling/heating cycles (ΔT > 500°C) without cracking1.

-

Mechanical Strength: Compressive strength > 300 MPa, suitable for heavy stacked loads.

-

Chemical Inertness: Resists acids, alkalis, and molten metals (e.g., Li-ion battery cathode materials).

3. Design Features

3.1 Stackable Architecture

-

Interlocking Rims: Ensures stable stacking with minimal lateral displacement.

-

Optimized Wall Thickness (10–20 mm): Balances thermal mass and heat transfer efficiency.

-

Precision-machined Surfaces: Flatness tolerance < 0.1 mm/m to prevent warping.

3.2 Customizable Configurations

-

Round/Rectangular Profiles: Adaptable to furnace layouts.

-

Perforated Designs: For gas flow control in reducing atmospheres.

-

Internal Coatings: Zirconia or silicon carbide layers to extend lifespan in corrosive environments.

4. Industrial Applications

| Industry | Use Case | Benefits |

|---|---|---|

| Electronics | Firing of MLCCs, ferrites, and semiconductor substrates | Contamination-free, high dimensional accuracy |

| Energy | Sintering of lithium battery materials (NMC, LFP) | Resists lithium salt corrosion |

| Metallurgy | Heat treatment of rare-earth alloys | Stable in hydrogen/nitrogen atmospheres |

| Advanced Ceramics | Production of structural ceramics (SiC, ZrO₂) | Reusable for 100+ cycles |

5. Advantages Over Traditional Saggers

-

vs. Mullite Saggers: 2× higher thermal conductivity (30 W/m·K vs. 15 W/m·K) for faster heating1.

-

vs. Silicon Carbide: Lower cost while maintaining >90% of SiC’s thermal performance.

-

vs. Cordierite: Superior lifespan (>5 years vs. 1–2 years under cyclic loading).

6. Innovations and Future Trends

-

3D-Printed Saggers: Additive manufacturing enables complex internal geometries for improved gas flow1.

-

Smart Saggers: Embedded IoT sensors for real-time temperature/stress monitoring.

-

Eco-Friendly Materials: Recycled alumina reduces production carbon footprint.

7. Conclusion

Stackable corundum saggers represent the pinnacle of kiln furniture technology, combining unparalleled thermal and mechanical properties with modular efficiency. As industries push toward higher-temperature processes and sustainable manufacturing, advancements in material science and design will further solidify their critical role.