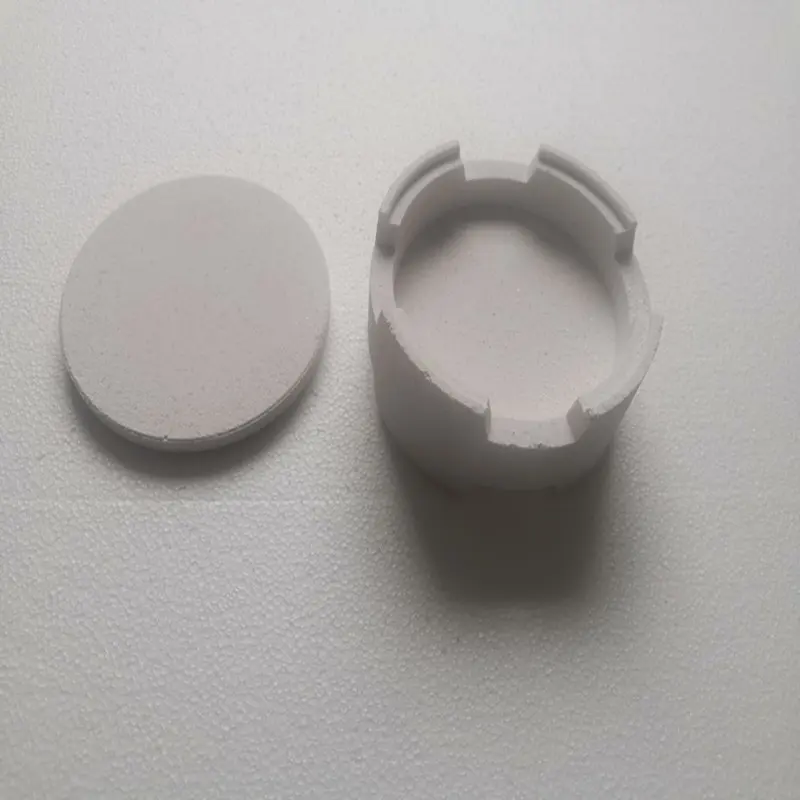

High temperature Corundum Mullite Saggers For Zirconia Teeth Sintering

Product Description

In the realm of dental ceramics, the importance of high-quality materials cannot be overstated. One such material that has gained significant attention is corundum mullite, particularly in the context of saggers used for zirconia teeth sintering. These specialized containers play a crucial role in the manufacturing process of dental prosthetics, ensuring optimal results and durability.

Product Feature

Corundum mullite saggers are designed to withstand the extreme temperatures and conditions present during the sintering process. Sintering is a critical step in the production of zirconia teeth, where the powdered zirconia is heated to high temperatures to achieve a dense, strong, and aesthetically pleasing final product. The use of corundum mullite saggers in this process offers several advantages, including excellent thermal stability, low thermal expansion, and resistance to chemical corrosion.

One of the primary benefits of using corundum mullite saggers for zirconia teeth sintering is their ability to maintain uniform temperature distribution. This is essential for achieving consistent sintering results, which directly impacts the mechanical properties and translucency of the zirconia. Additionally, these saggers minimize the risk of contamination during the sintering process, ensuring that the final dental products meet the highest standards of quality.

Moreover, corundum mullite saggers are lightweight and easy to handle, making them a practical choice for dental laboratories. Their durability also means that they can withstand multiple sintering cycles, providing a cost-effective solution for dental technicians.

Its standout feature is the exceptional thermal shock resistance, crucial for maintaining structural integrity under high-temperature compressive forces. Furthermore, the Corundum Mullite Sagger’s robust design ensures reliable performance against friction and thermal fluctuations, making it an ideal choice for applications that demand high endurance and efficiency.

Application Scope

Long-term usage temperature of 1700℃, outstanding thermal shock resistance, high compressive strength, good elastic modulus, and exceptionally long service life.

In conclusion, corundum mullite saggers are an indispensable tool in the production of zirconia teeth. Their unique properties not only enhance the sintering process but also contribute to the overall quality and longevity of dental ceramics. As the demand for high-performance dental materials continues to grow, the role of corundum mullite saggers will undoubtedly remain pivotal in the field of dental technology.