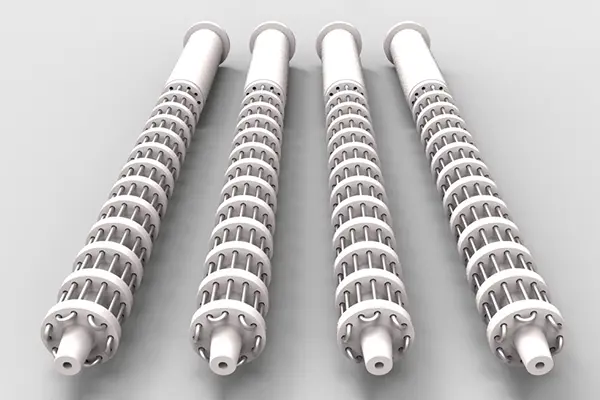

High Temperature Resistance Alumina Ceramic Disc For Heating Use

Product Feature

● High temperature resistance

● Strong thermal shock stability

● Resisting corrosion and stripping

● Long working life

● Effectively reduce probability of product's deformation, slag stripping etc defects

● Environment friendly

Product Parameter

|

Name |

Dense Cordierite |

Porous Cordierite |

Mullite |

Corundum mullite |

|

|

Density(g/cm3) |

2.1 ~2.5 |

1.5 ~1.9 |

2.0 ~2.5 |

2.3 ~2.7 |

|

|

Coefficient of heat expansion(×10-6K-1)(20~800°C) |

≤3.5 |

≤3.0 |

≤5 |

≤6 |

|

|

Specific Heat (J/Kg.K)(20~1000°C) |

900~1100 |

900~1100 |

1000~1150 |

1100 ~1300 |

|

|

Thermal Conductivity (W/m.k) (20~1000°C) |

1.5~2.5 |

1.2~1.8 |

1.5~2.0 |

1.5~2.5 |

|

|

Impact Thermal Resistance(°C/min) |

≥300 |

≥350 |

≥350 |

≥300 |

|

|

Max. Working Tem.(°C) |

1300 |

1300 |

1450 |

1550 |

|

|

Water absorption(%) |

≤2 |

15~25 |

15~25 |

15 ~25 |

|

|

Compressive strength(MPa) |

≥28 |

≥25 |

≥28 |

≥30 |

|

|

Chemical composition (%) |

Al2O3 |

25 ~38 |

28 ~38 |

60 ~70 |

70 ~80 |

|

SiO2 |

50 ~60 |

45 ~55 |

25 ~35 |

15 ~25 |

|

|

MgO |

5 ~10 |

11 ~14 |

0 ~1 |

0 ~2 |

|

|

others |

<5 |

<5 |

<5 |

<5 |

|

Application Area

Electric Appliance Industry

Automotive Industry

Mechanical Industry

Metal Smelting

Product Detail

Our Factory

FAQ

-

1. How can you get quotation ?

-

2. How can you get samples ?

A: We can supply free samples if we have them in stock. If we haven’t produced the products, we can supply some free samples after getting mold fee. Please take note that the courier fee should be at destination. -

3. Are you trade company or manufacturer ?