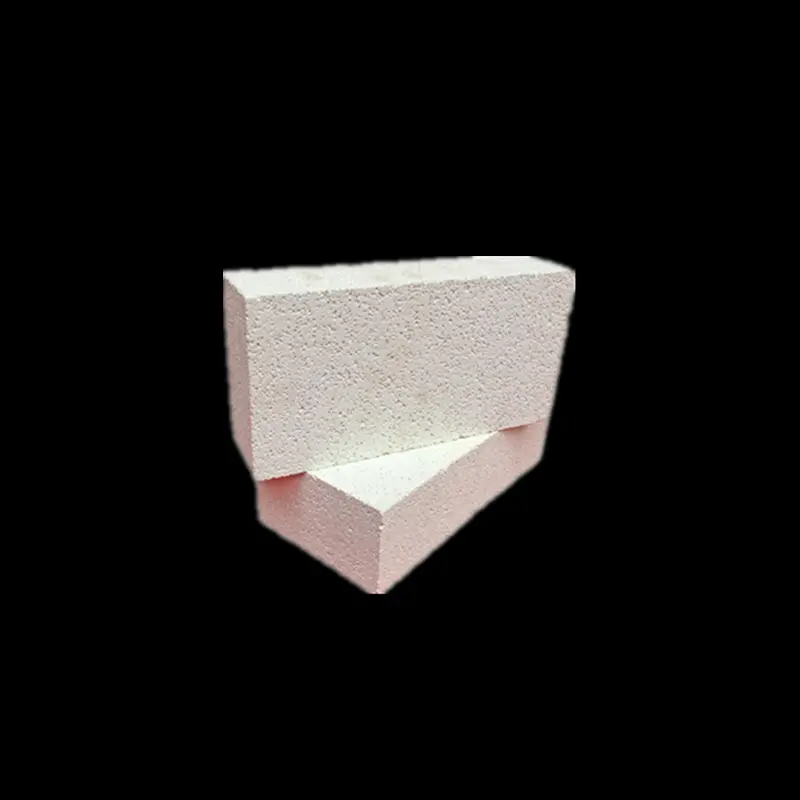

High Temperature Resistance Refractory Mullite Lightweight Bricks For Kiln

Product Feature

● High refractoriness, up to 1790℃ or above;

● Load softening starting temperature between 1600 and 1700℃;

● Extremely low thermal conductivity, usually between 0.21 and 0.40 W/m·K;

● Good thermal shock resistance;

● High hot compressive strength;

● Precise appearance dimensions, faster masonry speed.

Product Parameters

|

Item/Category |

JT23 |

JT26 |

JT28 |

JT30 |

JT32 |

|

(℃) Using temp |

1300 |

1430 |

1520 |

1550 |

1600 |

|

(g/cm3) Density |

0.55-0.65 |

0.8 |

0.9 |

1 |

1.1 |

|

(%) Reheating linear shrinkage |

0.4 |

0.5 |

0.8 |

0.8 |

1 |

|

(Mpa) Cold crushing strength |

1.8 |

1.8 |

2.5 |

2.8 |

3.5 |

|

(Mpa) Room temperature flexural strength |

1.2 |

1.2 |

1.6 |

1.6 |

2.2 |

|

(350℃ W/mk) Thermal Conductivity |

0.25 |

0.26 |

0.32 |

0.37 |

0.42 |

|

(×10-6/℃) Thermal expansion coefficient |

0.47 |

0.47 |

0.48 |

0.48 |

0.49 |

|

Al2O3 |

45 |

54 |

64 |

72 |

80 |

|

Fe2O3 |

0.9 |

0.9 |

0.8 |

0.7 |

0.5 |

Product Parameters

● Metallurgical industry: Used for lining of blast furnaces, steelmaking furnaces, aluminum smelting furnaces, etc., to help improve thermal efficiency and extend equipment life.

● Ceramic industry: As a thermal insulation layer in ceramic kilns to protect other materials from high temperatures.

● Glass industry: Used in glass melting furnaces, annealing furnaces, etc., to help maintain the stability of the furnace temperature and reduce heat loss.

● Cement industry: Used in high-temperature equipment such as cement rotary kilns, providing good fire resistance and thermal insulation effects.

● Industrial furnaces: Applicable to the lining and thermal insulation layer of various industrial furnaces to ensure safety and efficiency under high temperature conditions.

● Petrochemical: Provide thermal insulation and fire resistance protection in high-temperature reactors in oil refining and chemical processes.

● Other fields: It can also be used in other processes that require high temperature environments such as heat treatment and welding.

These applications reflect the wide adaptability and importance of mullite insulation bricks in high temperature and harsh environments.

Iron & Steel

Non-ferrous Metals

Power Industry

Building Materials

Oil Industry

Non-ferrous Metals

Product Detail

Our Factory

FAQ

-

1. Can I get some samples ?

-

2. Do you receive customized order ?

-

3. What's the lead time ?

-

4. What's your payment terms ?

-

5. Are you a manufacturer or a trading company ?