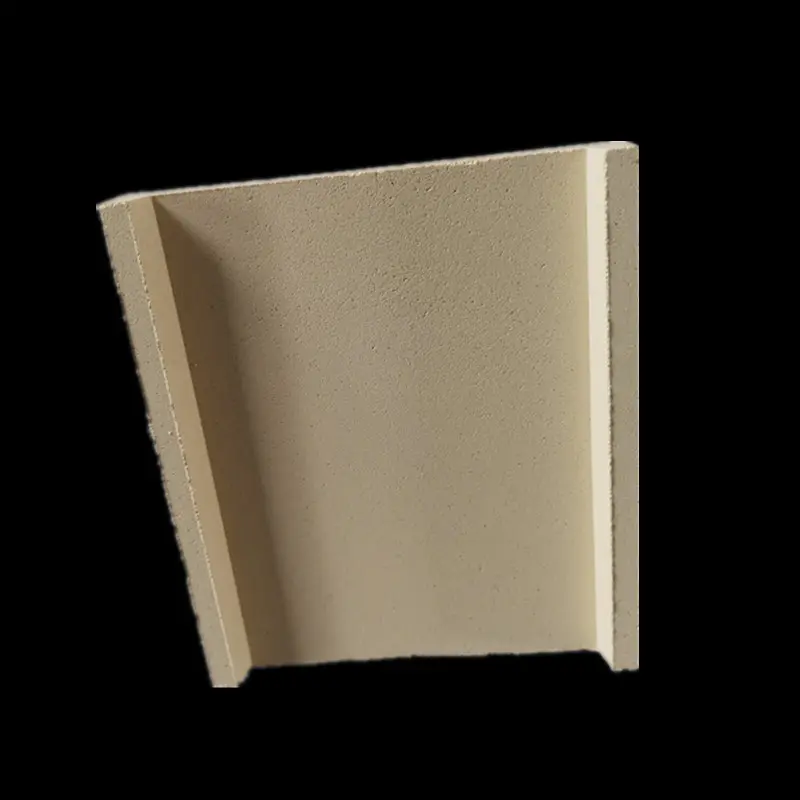

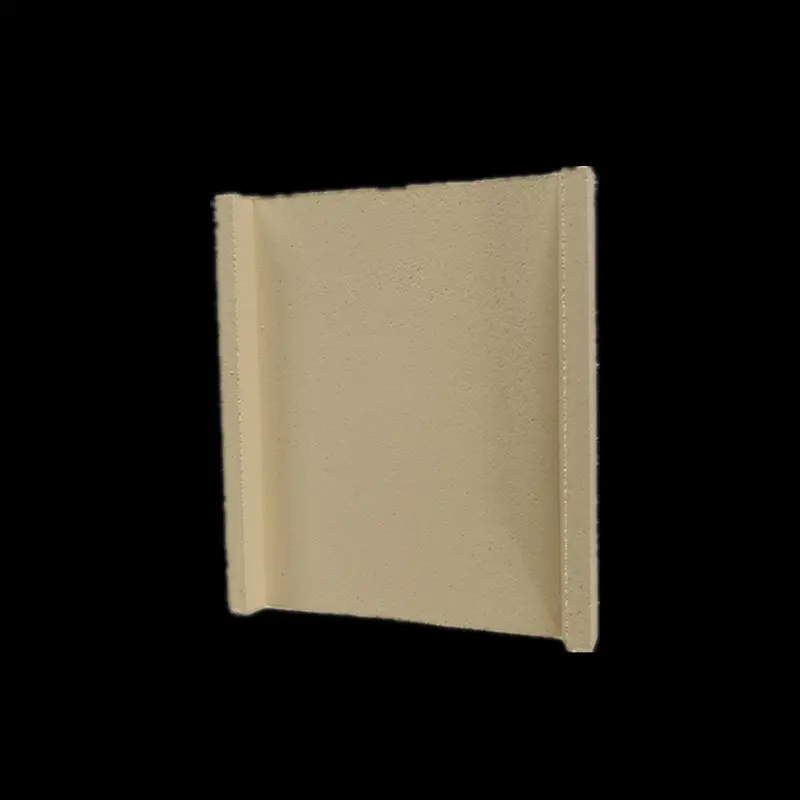

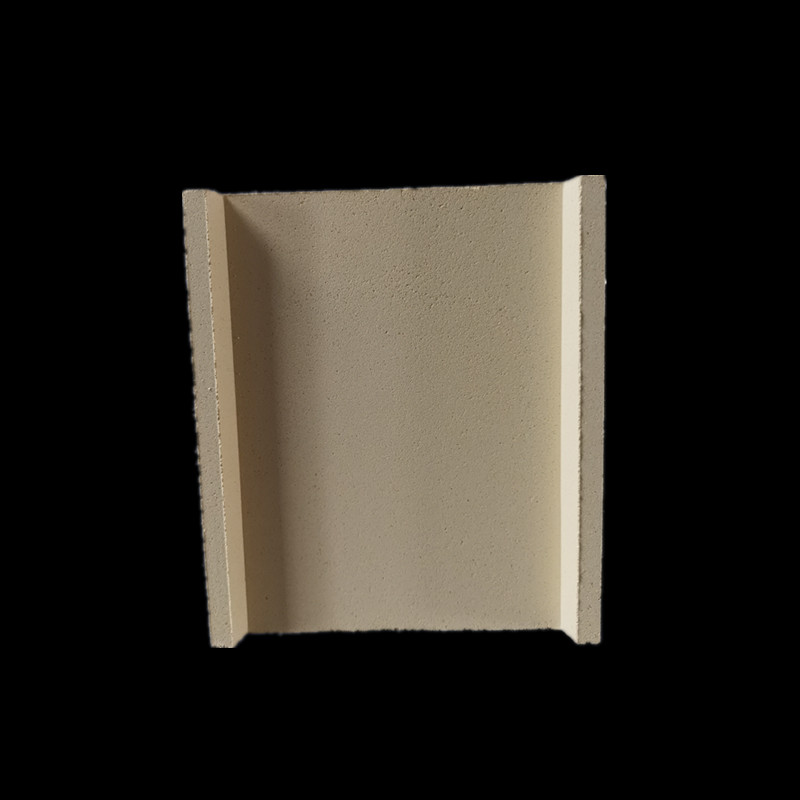

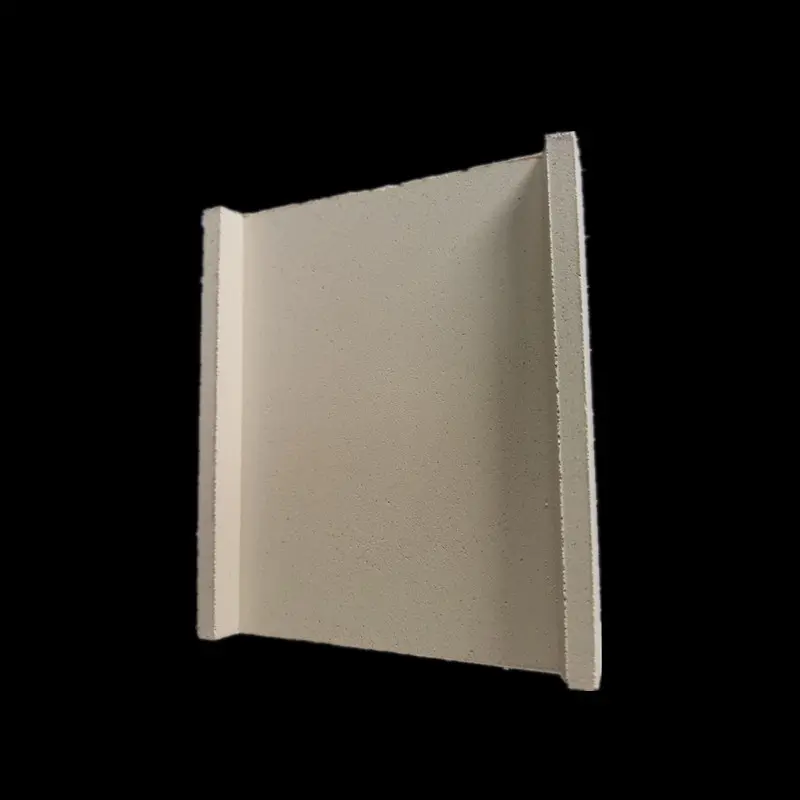

High temperature use Zirconia support trays for firing electronic components

In the realm of advanced manufacturing and electronics, the importance of high-quality materials cannot be overstated. One such material that has gained significant traction in recent years is zirconia, particularly in the form of zirconia support trays. These trays are essential for the firing of electronic components, providing a reliable and efficient solution for various applications in the electronics industry.

Zirconia, or zirconium dioxide (ZrO2), is a ceramic material known for its exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. These characteristics make zirconia an ideal choice for support trays used in the firing process of electronic components. The firing process, which involves subjecting components to high temperatures to achieve desired physical and chemical properties, requires materials that can withstand extreme conditions without deforming or reacting adversely.

One of the primary advantages of zirconia support trays is their ability to maintain structural integrity at elevated temperatures. During the firing of electronic components, temperatures can reach upwards of 1500°C. Zirconia support trays can endure these conditions without losing their shape or compromising the quality of the components being fired. This stability is crucial, as any deformation of the support tray can lead to misalignment or damage to the electronic components, ultimately affecting their performance and reliability.

Moreover, zirconia support trays exhibit excellent thermal insulation properties. This is particularly beneficial in the firing process, as it helps to minimize heat loss and ensures that the components are evenly heated. Uniform heating is essential for achieving consistent results, as it allows for the proper sintering of materials and the elimination of defects. By using zirconia support trays, manufacturers can enhance the efficiency of their firing processes, leading to improved product quality and reduced production times.

Another significant benefit of zirconia support trays is their chemical inertness. In the context of firing electronic components, it is vital that the support material does not react with the components or the atmosphere within the firing chamber. Zirconia’s resistance to chemical reactions ensures that the integrity of the electronic components is preserved throughout the firing process. This characteristic is particularly important when working with sensitive materials that may be adversely affected by contaminants or reactive substances.

In addition to their functional advantages, zirconia support trays are also lightweight and easy to handle. This makes them a practical choice for manufacturers who require efficient and effective solutions for their firing processes. The ease of handling can lead to reduced labor costs and improved workflow, further enhancing the overall efficiency of production.

As the demand for high-performance electronic components continues to grow, the role of zirconia support trays in the manufacturing process becomes increasingly critical. Their unique properties make them an indispensable tool for ensuring the quality and reliability of fired components. Manufacturers looking to optimize their production processes should consider the integration of zirconia support trays into their operations.

In conclusion, zirconia support trays are a vital component in the firing of electronic components, offering numerous advantages such as high-temperature stability, excellent thermal insulation, chemical inertness, and ease of handling. As the electronics industry evolves, the reliance on advanced materials like zirconia will only increase, making these support trays an essential element in the quest for superior product quality and manufacturing efficiency.