-

Rich Industry Experience

+Kam Tai Refractories founded in 2006, the company is an economicentity integrating R&D, productionand sales. -

Strict Quality Management Process

+From raw material procurement todelivery, each process has a strictquality management process. -

Complete After-Sales Service System

+The perfect after-sales service systemcan solve practical problems thatarise for enterprises in a timely manner. -

Offer Favorable Cost

+Favorable purchasing costs andoptimized supply chain providecustomers with cost-effectiveproducts and services.

-

21+MFG Experience

-

120+Exporting Regions

-

100%Product Satisfaction

-

500MillionAn Annual Sales

In 2024

2024

Enter the automotive electronics industry. Became a partner of BYD’s new energy vehicle.

Delivery

step9

We have professional and reliable logistic partners, they can help to deliver cargo to all the world.

Package

step8

We make very good package and it will be very safe.

QC

step7

We have professional and advanced QC equipments.

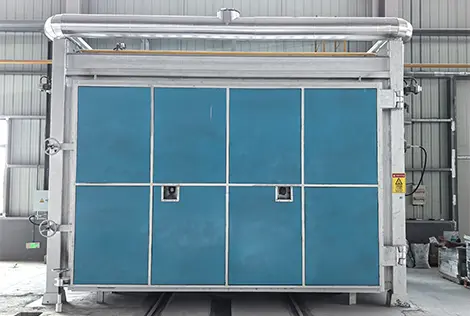

Sintering

step6

After drying, we will have firing process.We have professional automatic firing kilns.

Drying

step5

After moulding, we will have drying process.It is very important before firing.We have professional drying rooms.

Moulding

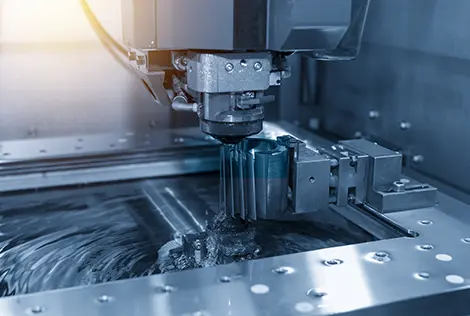

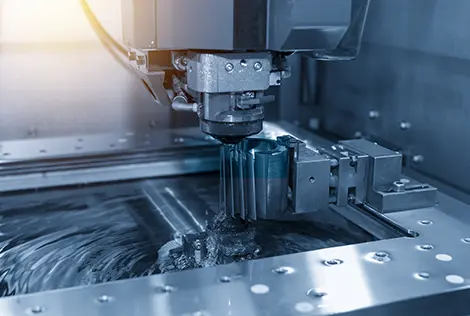

step4

We have large press machine for moulding.It can make our products better quality.

step3

AGING

After mixing and batching, we will have aging process. It can make the material more even.

Batching and mixing

step2

We have large capacity batching and mixing machine.We can have mass production quickly.

Raw material warehouse

step1

We have large warehouse for raw material storage and we will test raw material before using.Every kind of raw material is named and storaged in order.