Kiln Furniture for Vacuum Furnaces: The Silent Workhorses of High-Temperature Processing

Kiln Furniture for Vacuum Furnaces: The Silent Workhorses of High-Temperature Processing

Within the controlled, airless environment of a vacuum furnace, achieving precise thermal processing relies heavily on a critical, yet often understated, component: Kiln Furniture. These are the structural supports, setters, boats, trays, and other fixtures that hold, protect, and position the workload during heating, soaking, and cooling cycles. Unlike their counterparts in atmospheric furnaces, kiln furniture operating in vacuum faces a unique set of demands, making material selection, design, and maintenance paramount for successful and efficient operations.

Refractory Kiln Furniture in Industrial Furnaces: An Overview

In industrial thermal processing, kiln furniture—comprising various refractory components designed to support, protect, and transport materials during high-temperature operations—plays a critical role in ensuring efficient and reliable furnace performance. These components must withstand extreme temperatures (often exceeding 1600°C), rapid thermal cycling, mechanical stress, and chemical corrosion, all while maintaining structural integrity. This article explores the types, materials, and applications of refractory kiln furniture, emphasizing their significance in industries such as ceramics, metallurgy, glassmaking, and advanced materials manufacturing.

Ceramic Materials in New Energy Vehicles: Key Applications and Technological

The rapid development of new energy vehicles (NEVs), including electric vehicles (EVs) and hybrid electric vehicles (HEVs), has driven innovations in advanced materials to address challenges in energy efficiency, safety, thermal management, and lightweight design. Among these materials, ceramics have emerged as a cornerstone due to their unique properties, such as high thermal conductivity, electrical insulation, wear resistance, and structural stability. Below is an overview of the critical applications of ceramic materials in NEVs and their transformative roles.

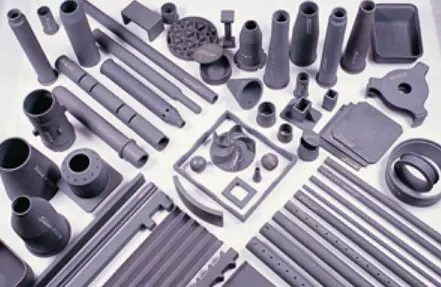

Applications of Pressureless Sintered Silicon Carbide

Pressureless sintered silicon carbide (SiC) is an advanced ceramic material renowned for its exceptional mechanical, thermal, and chemical properties, making it suitable for a wide range of demanding applications across various industries. Unlike traditional sintering methods that require external pressure, pressureless sintering allows for the production of complex-shaped components with high precision and cost-effectiveness, while still achieving near-theoretical density and superior performance.

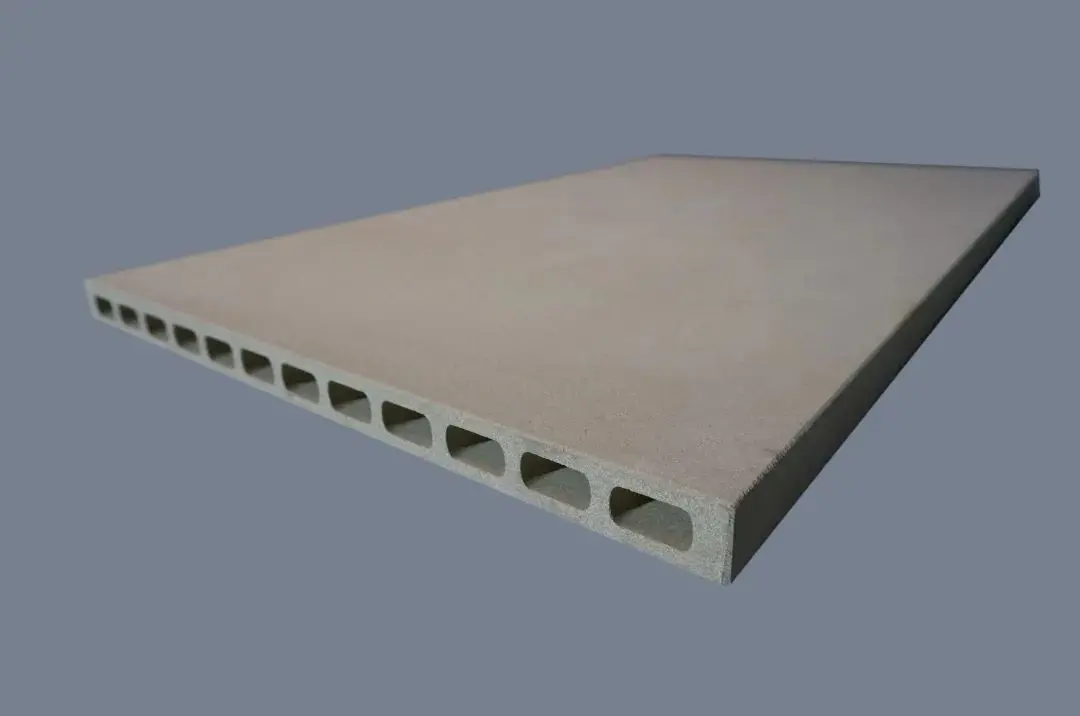

Extruded Cordierite Batts for Sanitary Ceramics in Kiln Applications

Extruded cordierite batts are a critical component in the firing of sanitary ceramics, providing essential support and thermal stability within industrial kilns. These batts are manufactured through an extrusion process, which ensures uniformity in density, dimensional accuracy, and structural integrity, making them highly reliable for high-temperature applications. Cordierite, a magnesium-aluminum-silicate ceramic (2MgO·2Al₂O₃·5SiO₂), is specifically chosen for its exceptional thermal shock resistance, low thermal expansion, and mechanical durability—properties that are indispensable in the demanding environment of sanitaryware production.

Application of Ceramic Rollers in Roller Hearth Kilns

Ceramic rollers, also known as ceramic roller tubes or ceramic roller bars, play a critical role in the efficient operation of roller hearth kilns, which are widely used in industries such as ceramics, metallurgy, glass, and electronics for high-temperature processing. These rollers are typically made from advanced ceramic materials such as alumina (Al₂O₃), silicon carbide (SiC), or mullite (3Al₂O₃·2SiO₂), chosen for their exceptional thermal stability, mechanical strength, and resistance to wear and corrosion. Their ability to withstand extreme temperatures—often exceeding 1600°C—makes them indispensable in continuous kiln systems where consistent material transport is essential.

Refractory Kiln Furniture in the Ceramic Tableware Firing Process

Refractory Kiln Furniture in the Ceramic Tableware Firing Process

The production of ceramic tableware involves a series of complex steps, with firing being one of the most critical stages. During this process, refractory kiln furniture plays an indispensable role in ensuring the proper sintering of ceramic products. Kiln furniture refers to the supporting structures and components used inside the kiln to hold, separate, and protect ceramic ware during high-temperature firing. These materials must withstand extreme thermal and mechanical stresses while maintaining dimensional stability and chemical inertness. This article explores the types, properties, and functions of refractory kiln furniture in the ceramic tableware firing process

The Production of Advanced Materials for New Energy Batteries

The development of new energy batteries, particularly lithium-ion batteries (LIBs), has revolutionized energy storage systems, enabling advancements in electric vehicles (EVs), renewable energy integration, and portable electronics. Central to these batteries are the electrode materials, electrolytes, and separators, each requiring precise synthesis and optimization for performance, safety, and cost-effectiveness. This article explores the key steps in manufacturing these critical components.

Applications of Magnetic Materials in Modern Industrial Production

Magnetic materials play a vital role in modern industrial production, with extensive applications in energy, electronics, transportation, healthcare, and smart manufacturing. Below are their key applications and future trends:

Characteristics and Applications of Recrystallized Silicon Carbide (R-SiC)

Recrystallized Silicon Carbide (R-SiC) is a pure silicon carbide ceramic material produced by high-temperature sintering of SiC powder (without sintering aids), resulting in grain growth and bonding. Its unique manufacturing process and microstructure give it exceptional performance, making it widely applicable in high-temperature, corrosive, and abrasive environments. Below are its key characteristics and applications.