The Application of Silicon Carbide Flame Spray Nozzle in Industrial Furnaces

Understanding Silicon Carbide Flame Spray Nozzles

Silicon carbide is a compound of silicon and carbon, known for its exceptional hardness, thermal conductivity, and resistance to wear and corrosion. These properties make silicon carbide an ideal material for flame spray nozzles, which are essential in various industrial applications, particularly in furnaces where high temperatures and abrasive conditions are prevalent.

The Application of Silicon Carbide Beams in Daily Ceramic Sintering

Silicon carbide (SiC) has emerged as a pivotal material in various industrial applications, particularly in the realm of ceramics. One of the most significant uses of silicon carbide is in the form of beams, which play a crucial role in the sintering process of ceramics. This article explores the application of Silicon Carbide Beams in daily ceramic sintering, highlighting their advantages and the impact they have on the efficiency and quality of ceramic products.

Silicon Carbide Ceramics: Market Overview and Application Field Analysis

Silicon carbide (SiC) ceramics have emerged as a pivotal material in various industries due to their exceptional properties, including high thermal conductivity, excellent wear resistance, and remarkable mechanical strength. As the demand for advanced materials continues to grow, the silicon carbide ceramics market is witnessing significant expansion. This article provides an overview of the silicon carbide ceramics market and delves into its application fields, highlighting the factors driving its growth and the challenges it faces.

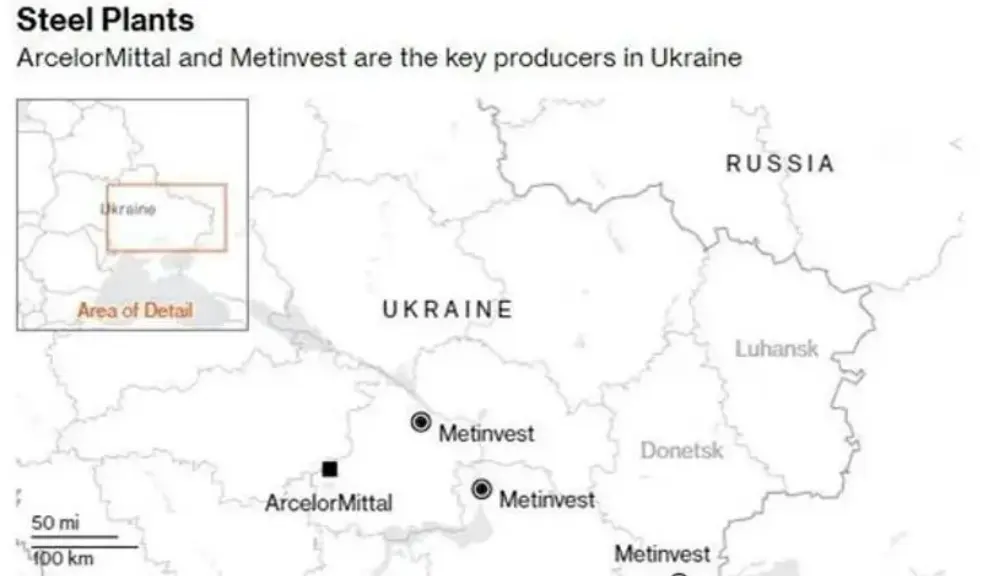

The Impact of the Russian-Ukrainian Conflict on the Global Refractory Industry

The ongoing conflict between Russia and Ukraine, which escalated dramatically in February 2022, has had far-reaching consequences across various sectors of the global economy. One of the industries significantly affected is the refractory industry, which plays a crucial role in manufacturing materials that can withstand high temperatures and harsh environments. This article explores the multifaceted impact of the Russian-Ukrainian conflict on the global refractory industry, examining supply chain disruptions, price volatility, and shifts in market dynamics.

The Impact of Refractory Materials on Modern Industry

Refractory materials play a crucial role in various industrial processes, serving as the backbone of high-temperature applications. These materials are designed to withstand extreme heat, corrosion, and mechanical stress, making them indispensable in sectors such as metallurgy, ceramics, glass manufacturing, and energy production. As industries evolve and demand for efficiency and sustainability increases, the impact of refractory materials on modern industry becomes even more pronounced.

Refractory Industry Status and Development: A Global Perspective

The refractory industry plays a crucial role in various sectors, including steel, cement, glass, and ceramics, by providing materials that can withstand extreme temperatures and harsh environments. As of October 2023, the global refractory industry is experiencing significant transformations driven by technological advancements, changing market dynamics, and increasing environmental regulations. This article explores the current status and development trends within the refractory industry on a global scale.

Corundum Brick: The Pinnacle of High-Temperature Refractory Materials

Corundum Brick, a vital component in the realm of refractory materials, is renowned for its exceptional properties and versatility in high-temperature applications. Made from high-purity fused corundum and super micro powder, these bricks are formed under high pressure and subjected to high-temperature sintering, resulting in a product that stands out in both performance and durability.

Application of Mullite Lightweight Insulation Brick

Mullite lightweight Insulation Bricks have emerged as a vital component in various industries due to their exceptional thermal properties and lightweight nature. These bricks, primarily composed of mullite, a silicate mineral, are known for their high-temperature resistance, low thermal conductivity, and mechanical strength. As industries continue to seek energy-efficient and cost-effective solutions, the application of mullite lightweight insulation bricks has gained significant traction.

13 Types of Refractory Materials and Their Applications

Refractory materials are used in various fields of the national economy, such as iron and steel, nonferrous metal, glass, cement, ceramics, petrochemical, machinery, boiler, light industry, electric power, military industry, etc. It is an essential basic material to ensure the production and operation of the above-mentioned industries and the development of technology. In this article, we'll take a look at the types of refractory materials and their applications.

The Role of Refractory Sagger in Alumina Powder Sintering

In the realm of advanced ceramics and materials science, the sintering process plays a pivotal role in determining the final properties of ceramic products. Among the various materials involved in this process, alumina powder stands out due to its exceptional hardness, thermal stability, and chemical resistance. However, the successful sintering of alumina powder is heavily reliant on the use of refractory saggers, which serve as essential components in the sintering process.