What is Alumina Ceramic Injection Molding?

Alumina ceramic is the most widely used special ceramic materials in industry. It is not only cheap and easy to obtain, but also has high mechanical properties, high electrical insulation and low dielectric loss. Therefore, it is used in aerospace, machinery, It is widely used in the fields of electronics, electric power, automobile, chemical industry, medicine and so on.

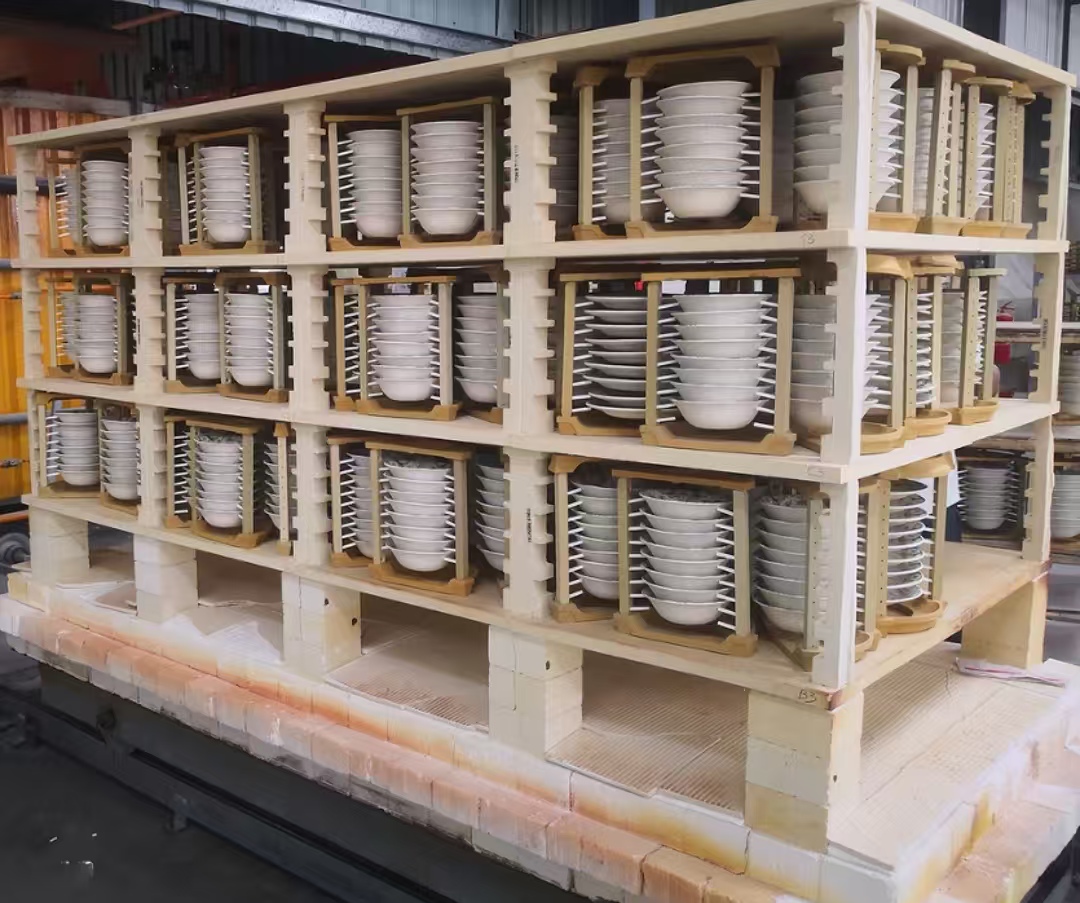

Functions of Kiln furniture

Functions of Kiln Furniture include carrying the kiln/furnace load and protecting the load from various kind of damage: open file, smoke, debris, from deforming or sticking the components to each other. In addition to various carriers and plates, capsules with heating material may be used

Application of refractory materials in modern production

Refractory materials refer to materials that can maintain their shape and performance under high temperature environments. They are widely used in many industrial fields such as metallurgy, ceramics, glass, cement, etc. With the continuous advancement of modern production technology, the application of refractory materials has become increasingly widespread and has become an indispensable and important part of modern industry.

99% Alumina ceramic's application

99% alumina ceramic, known for its exceptional hardness and durability, has become a material of choice in various industries. This high-purity ceramic is composed primarily of aluminum oxide (Al2O3), which contributes to its impressive mechanical properties, thermal stability, and resistance to wear and corrosion. As a result, 99% alumina ceramic finds extensive applications across multiple sectors.

What is kiln furniture ?

Kiln furniture are devices and implements inside furnaces used during the heating of manufactured individual pieces, such as pottery or other ceramic or metal components.Kiln furniture is made of refractory materials, i.e., materials that withstand high temperatures without deformation.Kiln furniture can account for up to 80% of the mass of a kiln charge.

Refractory Saggar: Applications in Powder Firing

Refractory saggars are essential components in the ceramics and metal industries, particularly in processes involving high-temperature firing. These specialized containers are designed to protect delicate items during firing, ensuring that they maintain their integrity and quality. One of the most significant applications of refractory saggars is in powder firing, where they play a crucial role in achieving optimal results.