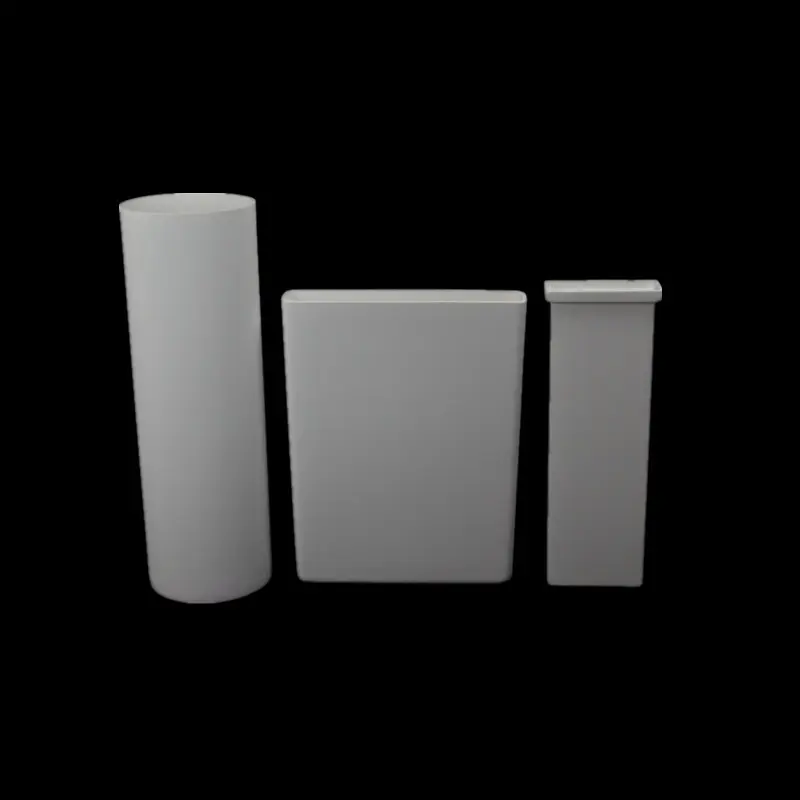

Porous Electrolytic Ceramic Diaphragm In Chrome Electroplating

Product Descripition

Electrolytic ceramic diaphragm is also called sinter tube (barrel), electrolytic ceramic cylinder, trivalent chrome ceramic gall, porcelain gall, regenerative ceramic pot, trivalent chrome electrolysis machine and so on. This electrolytic unglazed diaphragm cell is a plastic electroplating roughening liquid regeneration device, which realizes the automation of the roughening regeneration process and is simple in operation. It is widely used in Japan's plastic plating industry and China's domestic large-scale plastic plating factories, especially used in those high-quality parts, such as automotive plastic parts, bathroom parts, etc., In Japan, companies such as Toyota, Nissan, and TOTO Sanitary are all using this product. The cell can prevent the aging of the roughening liquid, reduce the concentration of trivalent chromium in the roughening liquid, maintain a good roughening effect, reduce the cost of replacing the bath, and greatly reduce the environmental pollution of chromic acid.

Product Feature

● High density, high purity

● Good wear-resistant, sealing ability

● Good tensile strength

● Good high temperature tolerance

● Excellent cold crushing and thermal shock resistance

● Excellent chemical stability and corrosion resistance

● No staining for long-term use

Product Parameter

|

Properties |

99% Alumina |

|

Color |

white |

|

Porosity |

>40% |

|

Bulk Density (g/cm3) |

3.9 |

|

Aperture |

0.5~2um |

|

Flexural strength |

>20MPa |

|

Acid resistance |

>99% |

|

Alkali resistance |

>94% |

Application Area

● Minig opening, chemical, electroplating, electrolyzation, waste water treatment, pure water treatment, high temperature flue gas filtration.

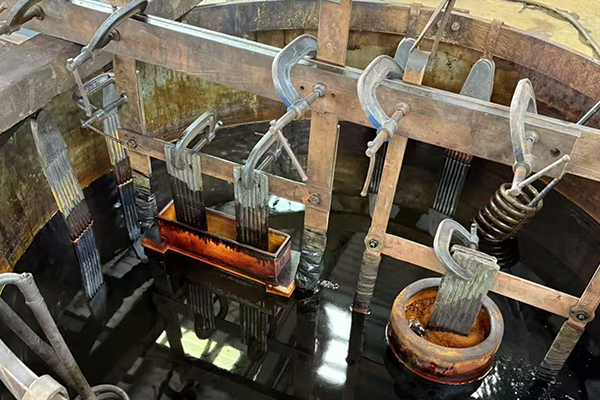

Electrolytic ceramic diaphragm cell is mainly used in the electroplating industry for the following two aspects:

1. Reduce the trivalent chromium of the roughening liquid by the principle of electrolytic oxidation reduction. The quality of the rough process of ABS plastic plating directly affects the plating quality of the plastic parts. During the roughening process, the hexavalent chromic acid in the roughening solution reacts with the product to form trivalent chromium and organic matter. And the hexavalent chromium becomes trivalent chromium, and as the content of trivalent Chromium increases, the oxidizing ability of the roughening liquid will be weakened, and the rate of formation of hydrophilic polar groups with ABS will decrease sharply, resulting in a decrease in the roughening effect. The adhesion between the plastic workpiece and the plating layer will be obviously reduced due to poor roughening. When the trivalent chromium concentration rises above 30 grams per liter, it will seriously affect the roughening quality and cause the roughening liquid to be scrapped. The waste liquid contains a lot of chromic anhydride and sulfuric acid, and it is not only a waste of resources, but also a serious pollution of the environment. Foreign countries (especially the automotive industry) have long adopted ceramic diaphragm electrolysis technology to reduce trivalent Chromium and regenerate the roughening liquid, thus achieving the goal of energy conservation and environmental protection.

2. Used in decorative chrome-plating and hard chrome-plating to remove impurities. In the production of decorative chrome and hard chrome, due to the uncleanness of the workpiece, the impurity cations in the plating tank are gradually increased. Too many impurities will cause the color and performance of the chrome plating to decrease, and even make the plating solution scrap. It costs much electricity and takes a long time. The electrolytic ceramic diaphragm cell is used to treat the plating solution, which can better remove the impurity cations in the plating solution, thereby improving the quality of the electroplating product and prolonging the service life of the plating solution.

Minig Opening

Chemical

Electroplating

Electrolyzation

Waste Water Treatment

Pure Water Treatment

High Temperature Flue Gas Filtration

Our Factory

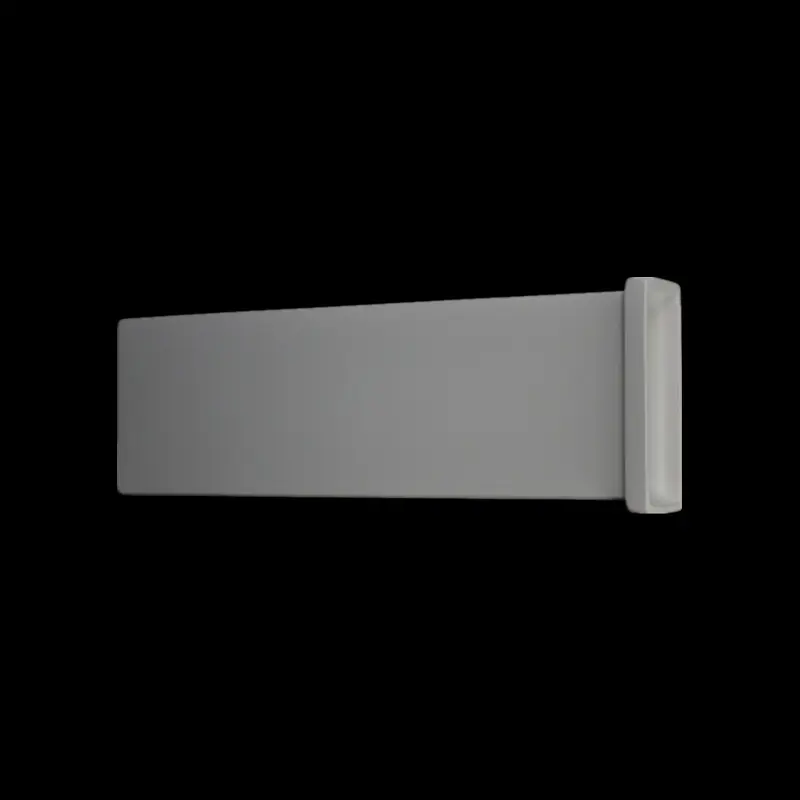

Product Detail

FAQ

-

1. Do you offer samples ?

A: Yes, we'll offer you samples if we have stock, but some will charge sample fee. Shipping cost will pay by customer. -

2. What is your terms of payment ?

-

3. How about your delivery time ?

-

4. How to contact us ?