High temperature resistance 95% Alumina ceramic...

When it comes to firing ceramics, the choice of kiln stilts is crucial for achieving optimal results. Among the various options available, alumina ceramic kiln stilts stand out for their durability and performance. These specialized supports are designed to elevate ceramic pieces during the firing process, ensuring that they do not come into contact with the kiln shelf, which can lead to unwanted sticking or damage.

High purity 99% Alumina ceramic setter plate fo...

In the realm of advanced manufacturing, Metal Injection Molding (MIM) has emerged as a revolutionary technique, allowing for the production of complex metal parts with high precision and efficiency. A critical component in the MIM process is the alumina ceramic setter plate, which plays a vital role in ensuring the quality and integrity of the final product.

High temperature Corundum Mullite Saggers For Z...

The Corundum Mullite Sagger is expertly designed to endure the challenging conditions of tooth sintering processes. This advanced sagger is specifically engineered to resist a variety of stress factors, including compression, thrust, and extreme temperatures.

High temperature resistance Silica bonded Silic...

Introducing our high-performance Silica Bonded Silicon Carbide kiln furniture, specifically designed for high-temperature industrial applications:

Refractory high temperature use Corundum-mulli...

Corundum-mullite is a composite material formed by the reaction of corundum (Al₂O₃) and mullite (3Al₂O₃·2SiO₂) at high temperatures. Its chemical formula is typically Al₄Si₂O₁₃, made up of varying proportions of corundum and mullite. This unique combination gives corundum-mullite excellent stability and performance at high temperatures.

- Corundum (Corundum): Made primarily of aluminum and oxygen, corundum is an extremely hard mineral (Mohs hardness 9), known for its excellent high-temperature resistance and chemical stability.

- Mullite (Mullite): A silicate mineral containing aluminum and silicon, mullite is famous for its low thermal expansion and good thermal shock resistance, making it commonly used in high-temperature ceramics.

High temperature resistance Corundum-mullite ce...

Ceramic setter trays play a pivotal role in ceramic kilns, ensuring the safe transport and firing of ceramic green bodies. With the sintering temperature for materials like MLCC (Multilayer Ceramic Capacitors) often exceeding 1200°C, the demand for high-specification ceramic setter trays is on the rise. Addressing this need, we introduce our top-tier corundum-mullite ceramic setter trays, designed for enhanced performance and longevity. Dive into the features, benefits, and applications of these state-of-the-art trays.

High wear resistance high strength zirconia c...

Zirconia ceramic, known for its exceptional strength, durability, and biocompatibility, has emerged as a revolutionary material in various industries, particularly in medical and dental applications. One of the most innovative uses of zirconia ceramic is in the production of zirconia ceramic needles, which are gaining popularity due to their unique properties and advantages.

High temperature resistance high strength Alumi...

Alumina ceramic stud is one of the most thermally resistant studs available. Due to their outstanding thermal resiustance, alumina ceramic studs are geared for the most demanding high temperature applications.

High temperature resistance High purity 99% Alu...

99% Alumina Ceramic Crucible: The Ideal Choice for High-Temperature Applications

In the realm of materials science and engineering, the 99% alumina ceramic crucible stands out as a premier choice for various high-temperature applications. Known for its exceptional thermal stability and chemical resistance, this type of crucible is widely utilized in laboratories, industrial settings, and research facilities.

High heat resistance cordierite ceramic setter ...

Cordierite (2MgO·2Al2O3·5SiO2) is a naturally occurring substance. It belongs to the silicate family and is composed of magnesium, aluminum, silicate, and iron elements. Cordierite ceramic was discovered in 1813 and got its name from the French geologist Louis Cordier.

High heat Resistance Refractory Cordierite plai...

Batts (otherwise known as plates, tiles and shelves) are used as a basic support element in most kiln and furnace structures, forming a flat, rigid surface which carries the ware during firing, sintering or heat treatment. Made from cordierite, they are flat, strong, and dependable products used throughout the ceramic industry for a range of applications (including biscuit, decorative and glost firings for the tableware industry, casting in the powder metal industry, and linings for the food industry).

High temperature refractory Cordierite mullite ...

A cordierite-mullite saggar was prepared via high-temperature sintering with cordierite, mullite and alumina (α-Al2O3) and yellow dextrin as raw materials.

High temperature resistance mullite ceramic was...

Ceramic washers are manufactured from steatite ceramic and alumina ceramic. Fully dense ceramic washers offer very good performance in terms of wear resistance, corrosion resistance and strength at a reasonable price. The high dielectric properties of steatite ceramic are beneficial in electronic products.

High temperature resistance silicon carbide pus...

Silicon carbide push plate is made of high-purity silicon carbide ceramic material, which has high hardness, high strength, high temperature stability and excellent wear resistance. It also has excellent chemical stability and good resistance to corrosive media such as acids and alkalis.

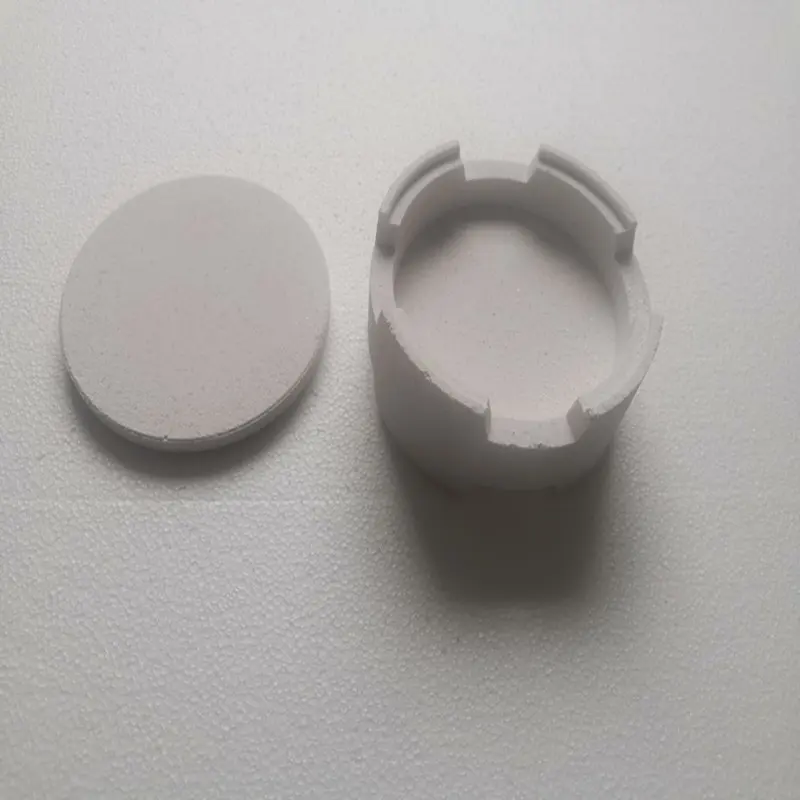

High heat resistance ceramic cuplocks for fixin...

Ceramic cuplocks have emerged as a revolutionary solution in the world of ceramics, particularly in the context of kiln operations. These innovative locking systems are designed to enhance the efficiency and effectiveness of kiln firing processes, making them an essential component for ceramic manufacturers and artists alike.

Alumina ceramic roller for heating use

Ceramic roller is a kind of refractory material in roller kiln, as the role of bearing and transmission in the furnace. Ceramic

rollers project is a key component of modern industrial track kilns, and can transmiss and bear ceramic products at temperatures

of up to 1400 °C