High temperature resistance alumina ceramic scr...

Introducing our premium Alumina Ceramic Screw, a cutting-edge solution designed for a variety of industrial and engineering applications. Crafted from high-purity alumina ceramic, these screws offer exceptional strength, durability, and resistance to wear and corrosion, making them an ideal choice for environments that demand reliability and performance.

Cordierite Mullite Setter Plate for Metal Firing

Mirror Polished Waterjet Ceramic Plunger Zircon...

Zirconium oxide ceramics are white, yellow or gray when containing impurities, and generally contain HfO 2, which is not easily separated. Pure ZrO2 has three crystal states under normal pressure.

The production of zirconia ceramics requires the preparation of high-purity, good dispersion properties, ultra-fine particles, narrow particle size distribution, zirconia ultrafine powder preparation methods, zirconia purification mainly chlorination and thermal decomposition, alkali metal Oxidative decomposition method, lime melting method, plasma arc method, precipitation method, colloid method, hydrolysis method, spray pyrolysis etc.

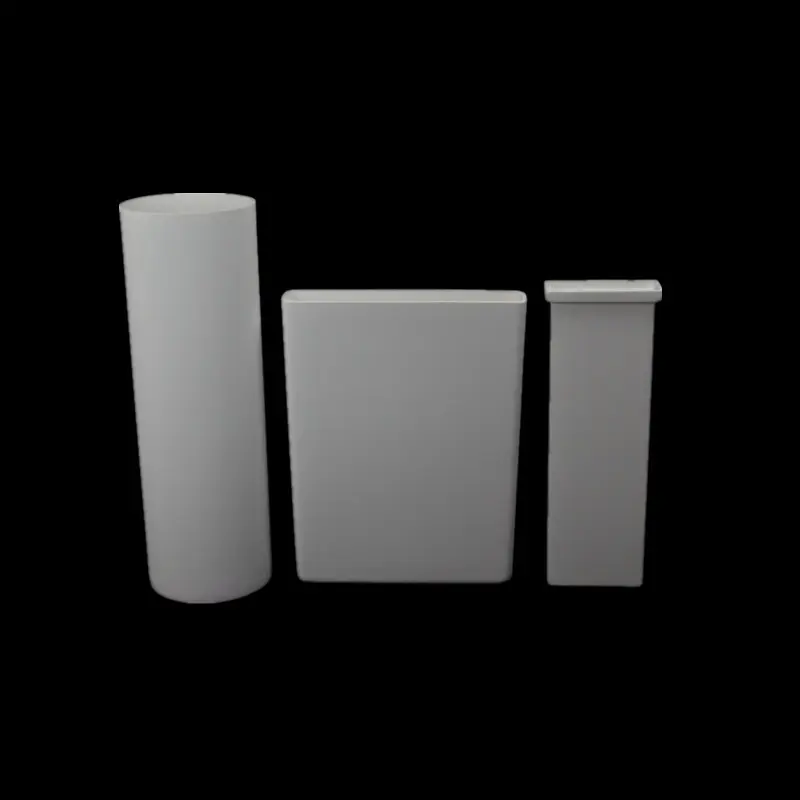

High Strength Alumina Ceramic Tube For High Tem...

Alumina ceramic tube high-performance materials made from aluminum oxide (Al2O3) and are widely used in various industrial applications due to their excellent mechanical, thermal, and electrical properties. Here are some key features and applications of alumina ceramic tubes.

Porous Electrolytic Ceramic Diaphragm In Chrome...

Electrolytic ceramic diaphragm is also called biscuit firing tube(barrel), electrolytic ceramic cylinder, Trivalent chromium ceramic gall, Porcelain gall, Regeneration ceramic tank, Trivalent chromium electrolysis machine and so on.

Electrolytic ceramic diaphragm is a plastic plating roughening liquid regeneration device, it can make roughening liquid of the regeneration process into automation, which is easy to operate.

95% Al2O3 Alumina Ceramic Engineering Alumina C...

Alumina ceramics have a very high temperature resistance and are able to remain intact and non-embrittlement at high temperatures. Therefore, alumina ceramics are often used in parts, electronic components, thermal components and other industries in high temperature environments.The hardness of alumina ceramics is very high, and can even reach the hardness level of quartz.

This makes alumina ceramics very wear-resistant and impact-resistant, and is widely used in protective materials, body ceramics and other fields.Due to the chemical stability of alumina, its ceramics can also have good corrosion resistance. Therefore, alumina ceramics are also widely used in chemical, pharmaceutical and other corrosive substance environment parts.

Custom High Strength 99% Al2o3 Alumina Ceramic ...

The Alumina ceramic plate is 99% pure alumina, which is chemically inert and dimensionally stable to 1800°C. Dense alumina ceramic plates have exceptional resistance to both oxidizing and reducing atmospheres at high temperatures and most corrosive environments and are normally used as hearth plates in rapid-heat electric furnaces.The alumina ceramic plate is the best choice in the sintering process for Metal Injection Molding, there are there ceramic materials to choose from for the MIM setter plate.

Aluminum Oxide(Al2O3) ceramic plate: lower cost and is the most popular ceramic setter plate for Metal Injection Molding.

High Temperature Resistance Alumina Ceramic Dis...

Alumina ceramic is made of aluminosilicate natural minerals as a main raw material, and is formed by a reaction sintering method in which a eucalyptus is synthesized in a sintering process or a mullite is first synthesized and then sintered.

Due to the low purity of raw materials and high impurity content, in addition to Al2O3 and SiO2, the components also contain impurities such as TiO2, Fe2O3, CaO, MgO, Na2O, K2O, etc., so that there are a considerable amount of glass phase in the product,resulting in mechanical and thermal properties. Poor, the excellent performance of mullite ceramics at high temperatures cannot befully utilized.

Therefore, ordinary mullite ceramics in the industry can only be used as a general refractory material in the case where the temperature and high temperature strength are not high.

High Heat And High Temperature Resistance Alumi...

Alumina ceramic (Aluminum Oxide, or Al2O3) is one of the most widely used technical ceramic materials, with an excellent combination of mechanical and electrical properties as well as a favorable cost-to-performance ratio. We offers a range of Alumina compositions to meet your most demanding applications.

Alumina components can be formed by a variety of manufacturing techniques such as dry pressing, isostatic pressing, injection molding, extrusion, and tape casting. Finishing can be accomplished by precision grinding and lapping, laser machining, and a variety of other processes.The alumina ceramic components are suitable for metallization in order to create a component that is easily brazed with many materials in subsequent operations.

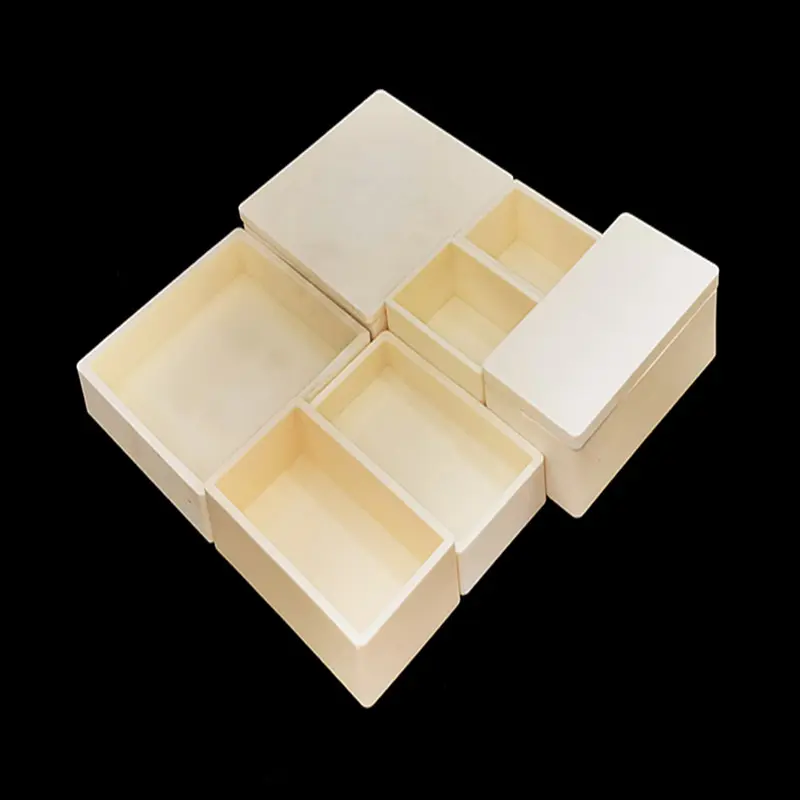

High Temperature Resistance Corundum Mullite sa...

The Corundum mullite Sagger offers an all in one solution for firing of either components or powders. These saggers can be stacked directly on top of each other at Temperatures up to 1500 ℃.

Reduced wall thickness over traditional high alumina or mullite refractory saggers can lead to increased product loading, further weight reduction, decreased cycle time.We produce saggers for the application range up to 1700°C.

We coordinate the respective sagger type and quality with our customers, depending on the chemical, thermal and geometric requirements. Our long years of experience in manufacturing saggers guarantees long service lives and high-speed heating cycles.

High Temperature Resistant Kiln Furniture Refra...

Cordierite mullite sagger is a sagger for sintering powder, which is made of sintered mullite, cordierite, fused magnesia alumina spinel, aluminum oxide micro powder, Guangxi white mud, etc. as raw materials, dextrin as binder by special process, and fired at appropriate temperature.

Cordierite Mullite Saggers Advantages: The Cordierite mullite saggar has excellent characteristics such as high fire resistance, high strength, excellent thermal shock resistance, small coefficient of thermal expansion, and strong resistance to Li and CO ion corrosion, with a service life of more than 60 times.

High Temperature Resistance Good Thermal Shock ...

Ceramic sagger is characterized by high purity (Al2O3≥92%) high density, good mechanical properties and stable chemical properties, is mainly used as linings for the kilns in ceramics and refractories industries and as high temperature devices for gasifier and gas generator in petrochemical industry. It is awarded the Third Prize of Science & Technology Progress by Sinopec and the former Ministry of Metallurgy Ministry.It is mainly used as high temperature (1350-1650℃) kiln linings or kiln furniture in ceramics and refractories industries, gas combustion furnace in petrochemical industry and other high temperature services where thermal shock happens frequently.

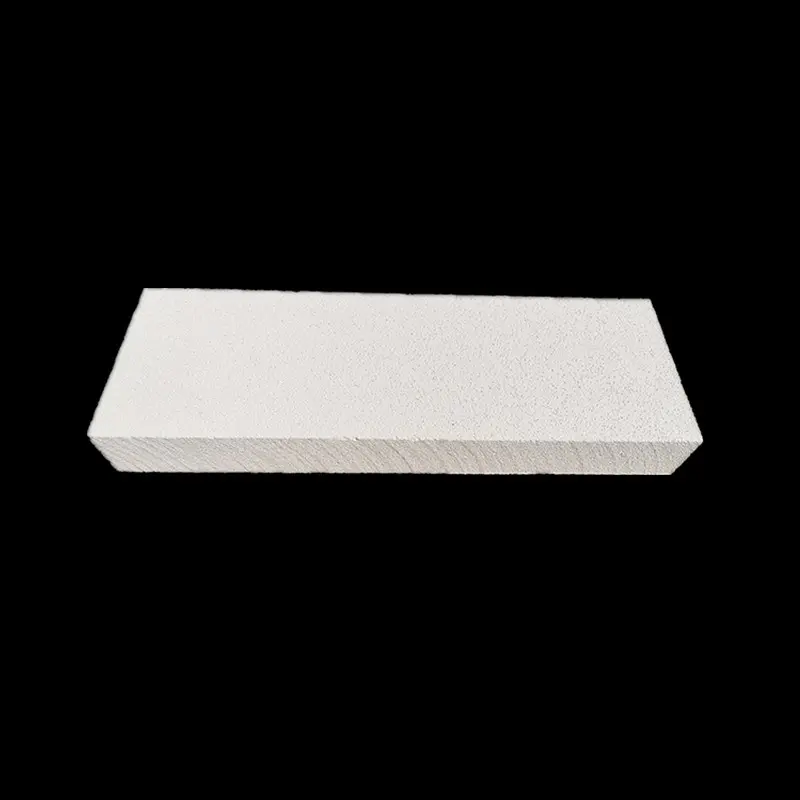

Refractory Materials Alumina Fireproof Brick Al...

Bubble alumina brick is a kind of light neutral heat preservation refractory material with super high temperature and energy saving. Alumina hollow ball bricks are not only small in body density, but can optimize the structure to reduce the weight of the furnace body, but also have low thermal conductivity, which has a good thermal insulation effect. It is mainly used as the lining of high-temperature industrial kilns below 1800°Cz such as petroleum, chemical, electronics, ceramics, refractory materials and other industries. It plays a pivotal role in various industries.

High Temperature Refractory Corundum Mullite Br...

Corundum-mullite brick refers to a high-aluminum refractory product composed of corundum and mullite main crystal phases. Corundum-mullite bricks refer to refractory products made of high-purity or relatively pure raw materials.

High Temperature Resistance Refractory Mullite ...

Mullite insulation brick is a lightweight refractory brick, the main component of which is mullite (3Al₂O₃·2SiO₂), a mineral material with high refractoriness and low thermal conductivity.

Mullite insulation brick is usually used in the thermal insulation layer of industrial kilns and thermal equipment. Its main purpose is to provide a thermal insulation effect while reducing heat loss and improving the thermal efficiency of the equipment.

High temperature resistance Corundum Mullite se...

In the realm of ceramics and high-temperature applications, the corundum mullite setter plate stands out as an essential component for achieving optimal results in kiln operations. These setter plates are specifically designed to withstand extreme temperatures, making them ideal for use in high-temperature kilns where traditional materials may fail.