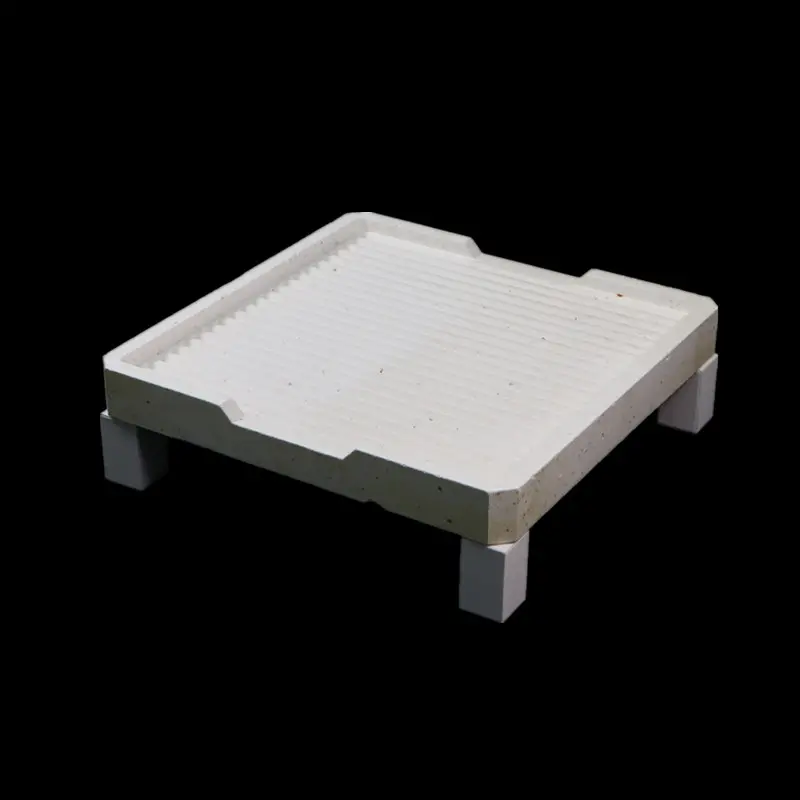

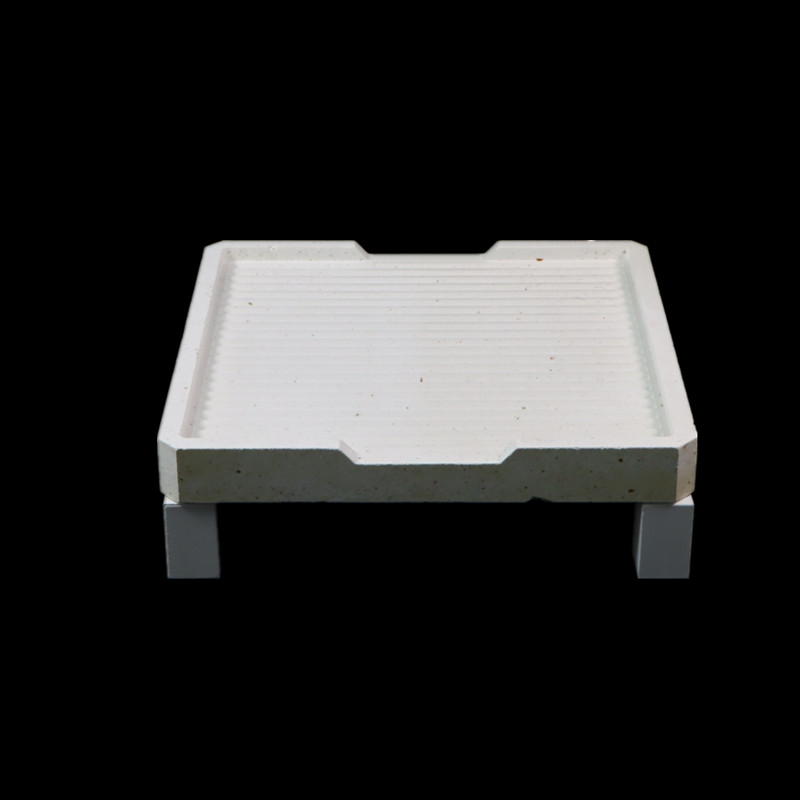

Refractory Andalusite(mullite ) Pusher Plates in High-Temperature Applications

Product Description

Andalusite is a naturally occurring aluminosilicate mineral that exhibits remarkable thermal stability and resistance to thermal shock. This makes it an ideal candidate for high-temperature applications where materials are subjected to extreme conditions. The use of andalusite pusher plates is particularly beneficial in processes that involve the handling of molten materials, as they can withstand the intense heat without deforming or degrading.

Product Feature

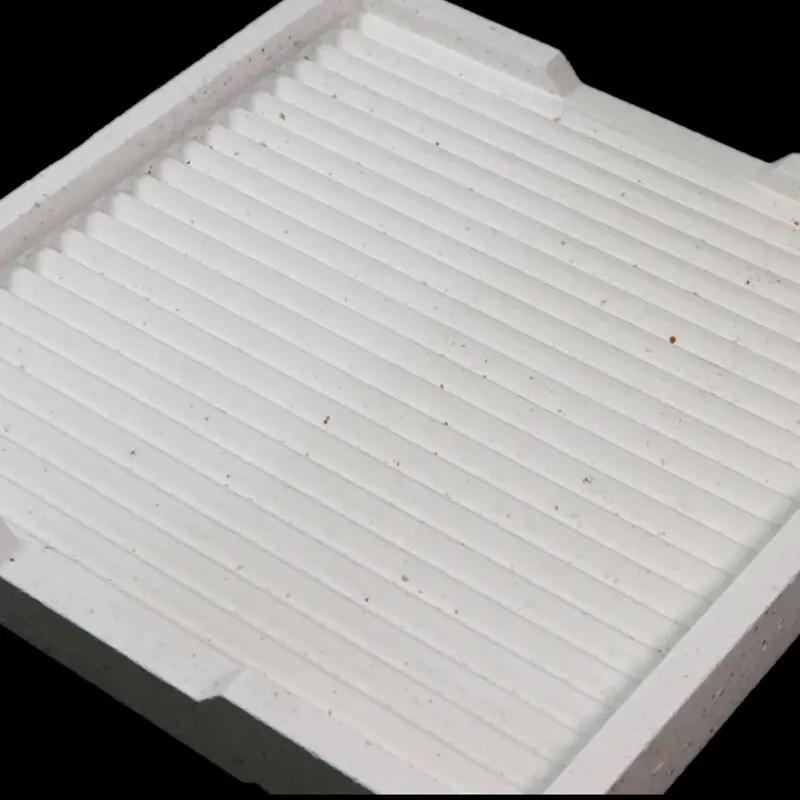

● Thermal stability

One of the primary advantages of andalusite pusher plates is their ability to maintain structural integrity at elevated temperatures. Unlike other materials that may warp or lose strength when exposed to high heat, andalusite retains its form, ensuring consistent performance in demanding environments. This characteristic is crucial in industries where precision and reliability are paramount, such as in the production of refractory materials and kiln linings.

● Wear resistance

In addition to their thermal stability, andalusite pusher plates also exhibit excellent wear resistance. In high-temperature applications, materials are often subjected to abrasive conditions that can lead to rapid wear and tear. The hardness of andalusite helps mitigate this issue, allowing pusher plates to endure prolonged use without significant degradation. This not only extends the lifespan of the plates but also reduces maintenance costs and downtime, making them a cost-effective solution for manufacturers.

● Environmental protection

Furthermore, andalusite pusher plates are also environmentally friendly. As a naturally occurring mineral, andalusite is abundant and can be sourced sustainably. This aligns with the growing trend towards eco-friendly practices in manufacturing, where companies are increasingly seeking materials that have a lower environmental impact. By utilizing andalusite pusher plates, manufacturers can not only improve their operational efficiency but also contribute to sustainability efforts.

In conclusion, andalusite pusher plates are emerging as a vital component in high-temperature applications across various industries. Their exceptional thermal stability, wear resistance, low thermal conductivity, and environmental benefits make them an ideal choice for processes that demand reliability and efficiency. As industries continue to evolve and seek innovative solutions to meet the challenges of high-temperature environments, the adoption of andalusite pusher plates is likely to increase, paving the way for enhanced performance and sustainability in manufacturing. With ongoing advancements in material science, the future looks promising for andalusite and its applications in high-temperature settings.