Mullite Setter Plate with Zirconia Coating for ...

In the realm of advanced ceramics and materials engineering, the importance of high-performance setter plates cannot be overstated. Among these, the mullite setter plate with zirconia coating has emerged as a critical component in the firing process of Mn-Zn ferrite cores. This article delves into the unique properties and advantages of using mullite setter plates with zirconia coating, particularly in the context of Mn-Zn ferrite core production.

Refractory Andalusite(mullite ) Pusher Plates i...

Andalusite Pusher Plates in High-Temperature Applications

In the realm of high-temperature applications, the choice of materials is critical to ensuring efficiency, durability, and performance. One such material that has gained significant attention is andalusite, particularly in the form of andalusite pusher plates. These plates are increasingly being utilized in various industries, including metallurgy, ceramics, and glass manufacturing, due to their unique properties and advantages.

High quality high strength refractory Corundum ...

Introducing our premium corundum mullite push trays, the ultimate solution for high performance applications in demanding environments. These trays are engineered to withstand extreme temperatures while maintaining exceptional strength and durability.

Manufacture Custom High Temperature Refractory ...

In the world of ceramics and pottery, the importance of firing techniques cannot be overstated. One of the most innovative tools that has emerged to enhance the firing process is the Sic Setter Plate. This specialized plate is designed to support and optimize the firing of dishware, ensuring that each piece is treated with the utmost care and precision.

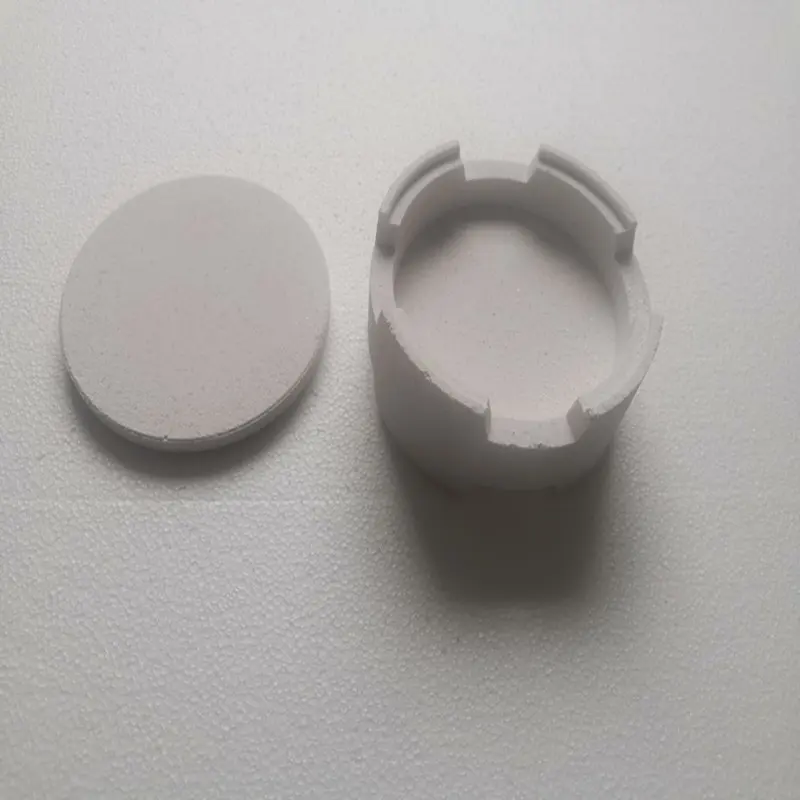

High temperature Corundum Mullite Saggers For Z...

The Corundum Mullite Sagger is expertly designed to endure the challenging conditions of tooth sintering processes. This advanced sagger is specifically engineered to resist a variety of stress factors, including compression, thrust, and extreme temperatures.

High temperature resistance Silica bonded Silic...

Introducing our high-performance Silica Bonded Silicon Carbide kiln furniture, specifically designed for high-temperature industrial applications:

Refractory high temperature use Corundum-mulli...

Corundum-mullite is a composite material formed by the reaction of corundum (Al₂O₃) and mullite (3Al₂O₃·2SiO₂) at high temperatures. Its chemical formula is typically Al₄Si₂O₁₃, made up of varying proportions of corundum and mullite. This unique combination gives corundum-mullite excellent stability and performance at high temperatures.

- Corundum (Corundum): Made primarily of aluminum and oxygen, corundum is an extremely hard mineral (Mohs hardness 9), known for its excellent high-temperature resistance and chemical stability.

- Mullite (Mullite): A silicate mineral containing aluminum and silicon, mullite is famous for its low thermal expansion and good thermal shock resistance, making it commonly used in high-temperature ceramics.

High temperature resistance Corundum-mullite ce...

Ceramic setter trays play a pivotal role in ceramic kilns, ensuring the safe transport and firing of ceramic green bodies. With the sintering temperature for materials like MLCC (Multilayer Ceramic Capacitors) often exceeding 1200°C, the demand for high-specification ceramic setter trays is on the rise. Addressing this need, we introduce our top-tier corundum-mullite ceramic setter trays, designed for enhanced performance and longevity. Dive into the features, benefits, and applications of these state-of-the-art trays.

High heat Resistance Refractory Cordierite plai...

Batts (otherwise known as plates, tiles and shelves) are used as a basic support element in most kiln and furnace structures, forming a flat, rigid surface which carries the ware during firing, sintering or heat treatment. Made from cordierite, they are flat, strong, and dependable products used throughout the ceramic industry for a range of applications (including biscuit, decorative and glost firings for the tableware industry, casting in the powder metal industry, and linings for the food industry).

High temperature refractory Cordierite mullite ...

A cordierite-mullite saggar was prepared via high-temperature sintering with cordierite, mullite and alumina (α-Al2O3) and yellow dextrin as raw materials.

High temperature resistance silicon carbide pus...

Silicon carbide push plate is made of high-purity silicon carbide ceramic material, which has high hardness, high strength, high temperature stability and excellent wear resistance. It also has excellent chemical stability and good resistance to corrosive media such as acids and alkalis.

Cordierite Mullite Setter Plate for Metal Firing

High Heat And High Temperature Resistance Alumi...

Alumina ceramic (Aluminum Oxide, or Al2O3) is one of the most widely used technical ceramic materials, with an excellent combination of mechanical and electrical properties as well as a favorable cost-to-performance ratio. We offers a range of Alumina compositions to meet your most demanding applications.

Alumina components can be formed by a variety of manufacturing techniques such as dry pressing, isostatic pressing, injection molding, extrusion, and tape casting. Finishing can be accomplished by precision grinding and lapping, laser machining, and a variety of other processes.The alumina ceramic components are suitable for metallization in order to create a component that is easily brazed with many materials in subsequent operations.

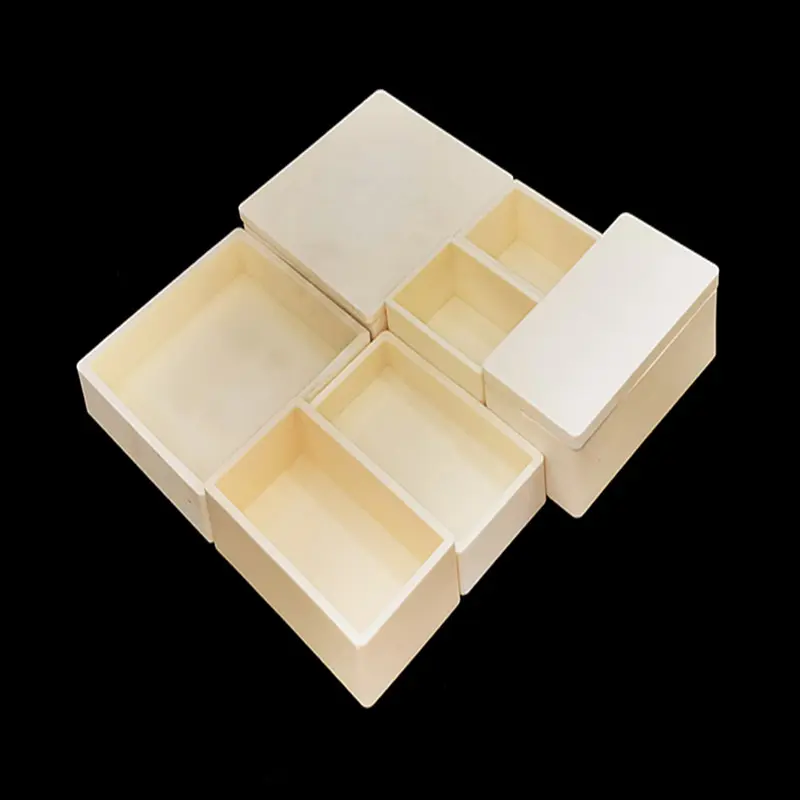

High Temperature Resistance Corundum Mullite sa...

The Corundum mullite Sagger offers an all in one solution for firing of either components or powders. These saggers can be stacked directly on top of each other at Temperatures up to 1500 ℃.

Reduced wall thickness over traditional high alumina or mullite refractory saggers can lead to increased product loading, further weight reduction, decreased cycle time.We produce saggers for the application range up to 1700°C.

We coordinate the respective sagger type and quality with our customers, depending on the chemical, thermal and geometric requirements. Our long years of experience in manufacturing saggers guarantees long service lives and high-speed heating cycles.

High Temperature Resistant Kiln Furniture Refra...

Cordierite mullite sagger is a sagger for sintering powder, which is made of sintered mullite, cordierite, fused magnesia alumina spinel, aluminum oxide micro powder, Guangxi white mud, etc. as raw materials, dextrin as binder by special process, and fired at appropriate temperature.

Cordierite Mullite Saggers Advantages: The Cordierite mullite saggar has excellent characteristics such as high fire resistance, high strength, excellent thermal shock resistance, small coefficient of thermal expansion, and strong resistance to Li and CO ion corrosion, with a service life of more than 60 times.

High Temperature Resistance Good Thermal Shock ...

Ceramic sagger is characterized by high purity (Al2O3≥92%) high density, good mechanical properties and stable chemical properties, is mainly used as linings for the kilns in ceramics and refractories industries and as high temperature devices for gasifier and gas generator in petrochemical industry. It is awarded the Third Prize of Science & Technology Progress by Sinopec and the former Ministry of Metallurgy Ministry.It is mainly used as high temperature (1350-1650℃) kiln linings or kiln furniture in ceramics and refractories industries, gas combustion furnace in petrochemical industry and other high temperature services where thermal shock happens frequently.