good wear resistance and insualtion Zirconia Ce...

Zirconia Ceramic Parts for Electronic Component Use: A Comprehensive Overview

In the realm of advanced materials, zirconia ceramic parts have emerged as a pivotal component in various industries, particularly in electronics. Zirconia, or zirconium dioxide (ZrO2), is a highly durable and versatile ceramic material known for its exceptional mechanical properties, thermal stability, and electrical insulation capabilities. This article delves into the significance of zirconia ceramic parts specifically designed for electronic component use, exploring their benefits, applications, and future prospects.

High temperature resistance high strength zirco...

Characteristics and Applications of Zirconia Ceramic Rods

Zirconia ceramic rods have gained significant attention in various industries due to their unique properties and versatile applications. Zirconia, or zirconium dioxide (ZrO2), is a highly durable ceramic material known for its exceptional mechanical strength, thermal stability, and resistance to wear and corrosion. These characteristics make zirconia ceramic rods an ideal choice for a wide range of applications, from industrial to medical fields.

High wear and high temperature resistance zirco...

The Application of Zirconia Ceramic Tubes: A Comprehensive Overview

Zirconia ceramic tubes have emerged as a vital component in various industries due to their unique properties and versatility. Composed primarily of zirconium dioxide (ZrO2), these tubes exhibit exceptional strength, thermal stability, and resistance to wear and corrosion. As a result, they find applications in fields ranging from medical technology to electronics and beyond.

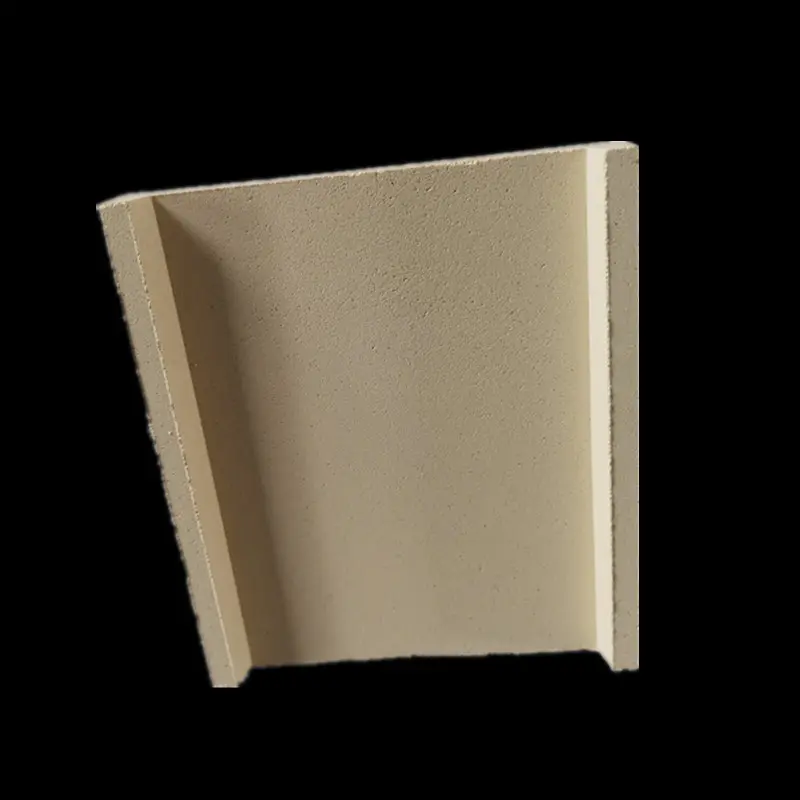

High Pure High Density High Wear Resistance Zir...

Zirconia, or zirconium dioxide (ZrO2), is a white crystalline oxide of zirconium. It is renowned for its remarkable mechanical properties, including high strength, toughness, and resistance to wear and corrosion. When processed into a ceramic plate, zirconia exhibits a unique combination of characteristics that set it apart from other materials. The high purity of zirconia ceramic plates ensures that they are free from contaminants, which is crucial in applications where material integrity is paramount.

High wear resistance Zirconia Ceramic Piston fo...

In the realm of engineering and manufacturing, the quest for materials that can withstand extreme conditions while maintaining performance is never-ending. One such innovation that has garnered significant attention is the zirconia ceramic piston. Known for its exceptional wear resistance, this advanced material is revolutionizing various industries, particularly in applications where durability and reliability are paramount.

High temperature use Zirconia support trays fo...

Zirconia support trays are a type of corrosion-resistant, high-temperature resistant rare-earth refractory material. They are often used as sintering pads for products such as dielectric ceramics, powder metallurgy, multilayer capacitors, and ferrite magnetic materials. These support trays are designed to prevent adhesion during the sintering of parts and to protect the electromagnetic properties of electronic components from degradation.

Zirconia Setter Plates for barium titanate capa...

The Role of Zirconia Setter Plates in Advanced Ceramic Applications

In the realm of advanced ceramics, particularly in the production of barium titanate capacitors, thermistors, and PZT (lead zirconate titanate) piezoelectrics, the importance of high-quality zirconia setter plates cannot be overstated. These setter plates play a crucial role in ensuring the integrity and performance of these sophisticated electronic components.

Insulating Customized High Hardness Mirror Poli...

Zirconia ceramics are used in shaft, plunger, sealing structure, auto mobile industrial, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts,applicable to aerospace, medical, food and other fields

High wear resistance high strength zirconia c...

Zirconia ceramic, known for its exceptional strength, durability, and biocompatibility, has emerged as a revolutionary material in various industries, particularly in medical and dental applications. One of the most innovative uses of zirconia ceramic is in the production of zirconia ceramic needles, which are gaining popularity due to their unique properties and advantages.

Mirror Polished Waterjet Ceramic Plunger Zircon...

Zirconium oxide ceramics are white, yellow or gray when containing impurities, and generally contain HfO 2, which is not easily separated. Pure ZrO2 has three crystal states under normal pressure.

The production of zirconia ceramics requires the preparation of high-purity, good dispersion properties, ultra-fine particles, narrow particle size distribution, zirconia ultrafine powder preparation methods, zirconia purification mainly chlorination and thermal decomposition, alkali metal Oxidative decomposition method, lime melting method, plasma arc method, precipitation method, colloid method, hydrolysis method, spray pyrolysis etc.